Looking For Quality Custom Injection Mold Manufacturer?

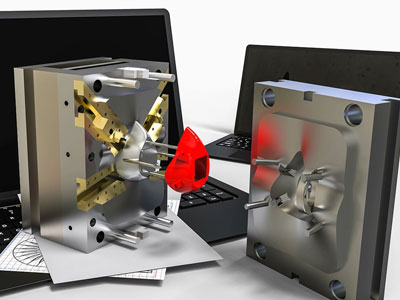

Expertise in Design

Specializing in mold designing that ensure precision, efficiency, and quality of plastic parts.

Rapid Prototyping

Providing quick turnaround times for prototype parts to validate designs before full production.

Customization

Offering tailored solutions to meet the unique requirements of different clients.

Competitive Pricing

Offering affordable solutions while maintaining quaility standards and durability.

About Us

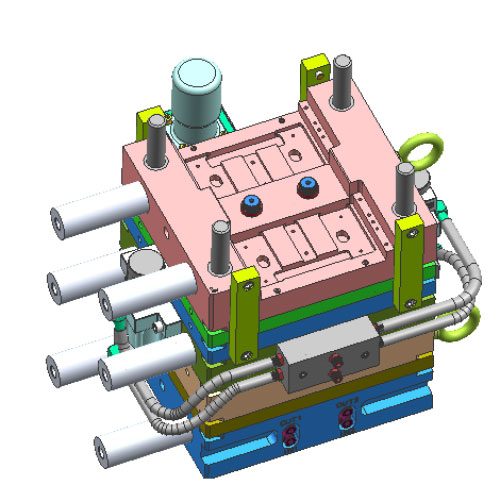

WIN WIN MOLD is a very professional plastic injection mould manufactory located Shenzhen of China. With 15+ years of development, it has grown up to an enterprise providing a full “turn key” services to the customers, starting with product design, prototype parts making, mold design, mold making and molding production etc. Moreover, we are specialized in plastic injection mold designing and manufacturing.

Business policy – long-term strategic planning, short-term goals, to achieve “common growth and shared achievements”.

Quality policy – environmental control, excellence, continuous improvement, customer satisfaction.

Quality objective – break through zero defects of products, and customer satisfaction is above 99%.

What we do

Our Services

Why Choose Us

Experienced staff

We have a team of skilled engineers and technicians to ensure high-quality, precise products.

Cost-Effective

We provide cost-efficient options without compromising quality.

Faster Turnaround

We use advanced technology and streamlined workflows to ensure quick product development.

Comprehensive Service

We offer full support throughout the entire process.

Application

Our products have a wide range of applications, such as automotive, electronics, healthcare, consumer goods etc. , to meet your diverse design needs and material specifications.

Medical & Health Care

Automotive Parts

Household Appliances

Telecommunication

Industrial Parts

CNC Machining Parts

our Clients

what They say

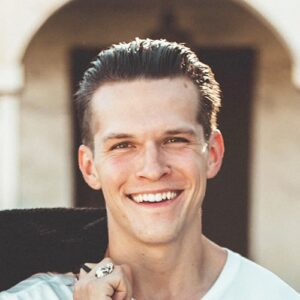

Robert Martin

Ohio,The US

“Winwinmold has always exceeded our expectations when it comes to their services and quality molded parts; their delivery schedules have always been impeccable.”

John Williams

California, The US

“Partnering with Winwinmold was one of the smartest decisions we made for product development. They provide high-quality parts, plus their team is always eager to collaborate with us.”

Tim Meier

Lower Saxony

“As an automotive part manufacturer, our production processes require precision and durability in every part produced. Winwinmold has been our go-to partner for our injection molding needs.”

contact us

Ready to bring your product ideas to life?

From concept to production, we offer precision, customization, and competitive pricing to meet all your molding needs. Let’s create the perfect mold together—reach out now for a consultation!