What is an intelligent mold? The word “intelligence” is a topic that everyone has been concerned about and curious about. There are intelligent robots, smart phones, intelligent sanitary systems… All intelligent products need to be manufactured on the basis of intelligent molds. So what is an intelligent mold? First, let’s talk about intelligent manufacturing equipment.

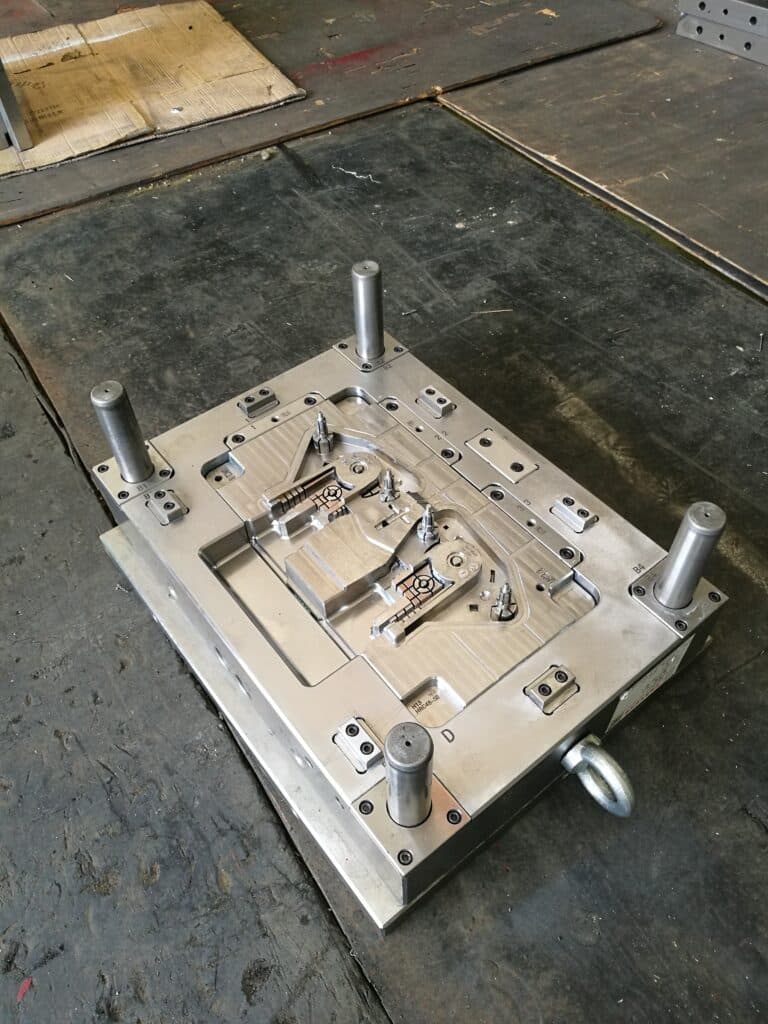

Intelligent manufacturing equipment is a manufacturing equipment with the functions of perception, analysis, decision-making and control. Intelligent molds also have the functions of perception, analysis, decision-making and control. Stamping molds and die-casting molds with the functions of sensing and temperature control, and injection molds with the functions of temperature control, injection molding parameters, flow state in the mold and other intelligent control methods are all intelligent molds.

Experts summarized the intelligent molds serving the emerging strategic industries: energy-saving and environment-friendly molds serving the energy-saving and environment-friendly industries.

Such molds mainly include molds serving for automobile energy conservation, emission reduction and lightweight, high light traceless and in mold assembly decorative molds, laminated molds and rotary molds, multi-color and multi material injection molds, multi-layer coextrusion composite molds, multi-functional composite efficient molds, LED new light source matching molds, and high-efficiency energy-saving silicon steel sheet stamping molds manufactured by intelligent control means such as injection parameters and flow status in the mold.

Precision and ultra precision molds with sensing functions serving the new generation of information technology industry. Such molds mainly include precision multi station progressive die for lead frame of large-scale integrated circuit, precision rubber and plastic packaging die for lead frame of multi cavity and multi injection head, high-precision high-speed multi station progressive die for electronic components and connectors, efficient multi row precision multi station progressive die for new generation electronic components and multi-function composite efficient forming die, intelligent forming die for plastic parts of new generation electronic products High precision multi-layer light guide plate mold and ultra precision mold for IoT sensors.

Intelligent mold has obvious advantages such as high technology content, high product added value, long service life, wide application range, and large market space. High, precision and sharp are the most obvious characteristics of intelligent mold. Using intelligent mold to produce products can further improve product quality and production efficiency, save materials, realize automatic production and green manufacturing. If it can be effectively used in traditional industries, intelligent molds will greatly improve the production efficiency of the existing manufacturing industry, and industrial transformation and upgrading can be better carried out. Intelligent molds are mainly divided into the following categories:

Multi-Cavities Molds

1、 Energy saving and environmental protection mould serving energy saving and environmental protection industry

(1) Mold for automobile energy conservation, emission reduction and lightweight service;

(2) High gloss non trace and in mold assembly decoration mold manufactured by intelligent control means such as injection molding parameters and in mold flow state;

(3) Laminated mold and rotary mold;

(4) Multi color and multi material injection mold;

(5) Multilayer co extrusion composite die;

(6) Multi functional composite efficient mold;

(7) LED new light source supporting mold;

(8) High efficiency energy-saving motor silicon steel sheet stamping die, etc.

2、 Precision and ultra precision molds with sensing functions serving the new generation of information technology industry

(1) Precision multi position progressive die for LSI lead frame;

(2) Multi cavity and multi injection head lead frame precision rubber and plastic packaging mold;

(3) High precision high-speed multi position progressive die for electronic components and connectors;

(4) New generation electronic components efficient multi row precision multi position progressive die and multi-function composite efficient forming die;

(5) Intelligent forming die for plastic parts of new generation electronic products;

(6) High precision multi-layer light guide plate mold;

(7) Ultra precision molds for IoT sensors.

3、 Precision and ultra precision molds for medical devices serving the biological industry

(1) To manufacture precision and ultra precision medical instrument injection molds through intelligent control methods such as plastic injection parameters and flow status in the mold;

(2) Metal (stainless steel, etc.) powder injection mold, biochip mold, etc.

4、 Intelligent mold for high-end equipment manufacturing industry

(1) Large precision stamping die for large CNC forming and stamping equipment;

(2) Precision forging die for heavy forging equipment;

(3) Large temperature controlled precision casting mould for clean and efficient casting equipment;

(4) Large precision plastic mould for nonmetal forming equipment;

(5) High grade radial tire and giant engineering tire mold;

(6) Large precision CNC adjustable non indentation bending die and intelligent bending die for large CNC bending machine and intelligent bending machine;

(7) Forming dies and rapid dies for special materials in aerospace and national defense industries;

(8) Special casting and forging dies and special non-ferrous metal stamping dies for aerospace and national defense industries;

(9) , EMU gearbox mould and ultra-high speed (>300km/h) precision bearing mould;

(10) Optical aspherical lens and special lens forming mould of military products;

(11) Plastic, metal and other materials ultra-thin ultra precision and micro special parts forming die;

(12) Metal and non-metallic materials rapid and efficient intelligent forming dies serving high-end manufacturing, etc.

5、 Mold for new energy industry

New blade mould, spindle mould and motor mould for megawatt wind turbine.

6、 Mold for new energy automobile industry

(1) New energy vehicle battery mold;

(2) . New energy vehicle transmission device mold;

(3) New energy vehicles use plastic instead of steel and light metal instead of steel mold;

(4) . Energy saving automobile hybrid power device mold;

(5) Hot forming die and multi station automatic stamping die for automobile covering parts.

Precision and ultra precision molds for medical devices serving the biological industry. This kind of mold is mainly used to manufacture precision and ultra precision medical instrument injection mold, metal (stainless steel, etc.) powder injection mold, biochip mold, etc., which are cutting-edge components of biological and medical industries through intelligent control methods such as plastic injection parameters and flow state in the mold.

Intelligent mold serving the “high-end equipment manufacturing industry”. Such molds mainly include large precision stamping molds for large CNC forming and stamping equipment, precision forging molds for heavy forging equipment, large temperature controlled precision casting molds for clean and efficient casting equipment, large precision plastic molds for non-metallic forming equipment, and molds for high-grade radial tires and giant engineering tires Large precision CNC adjustable non indentation bending die and intelligent bending die for large CNC bending machine and intelligent bending machine, special material forming die and rapid die for aerospace and national defense industry, special casting and forging die and special colored metal stamping die for aerospace and national defense industry, EMU gear box die and ultra-high speed (> 300 km/h) precision bearing die Optical aspherical lenses and special lens forming dies for military products, forming dies for ultra-thin and ultra-fine materials such as plastic metal and micro special parts, rapid and efficient intelligent forming dies for metal and non-metallic materials serving high-end manufacturing, etc.

Mold for new energy industry. This kind of mould mainly includes new blade mould, spindle mould and motor mould for megawatt wind turbine.

Mold for new energy automobile industry. Such moulds mainly include new energy automobile battery moulds, new energy automobile gear change device moulds, new energy automobile moulds that replace steel with plastics and light metals, energy-saving automobile hybrid power device moulds, automobile panel hot forming moulds and multi station automatic stamping moulds.