What are the methods for removing the material head left in the injection port of the plastic injection mold?

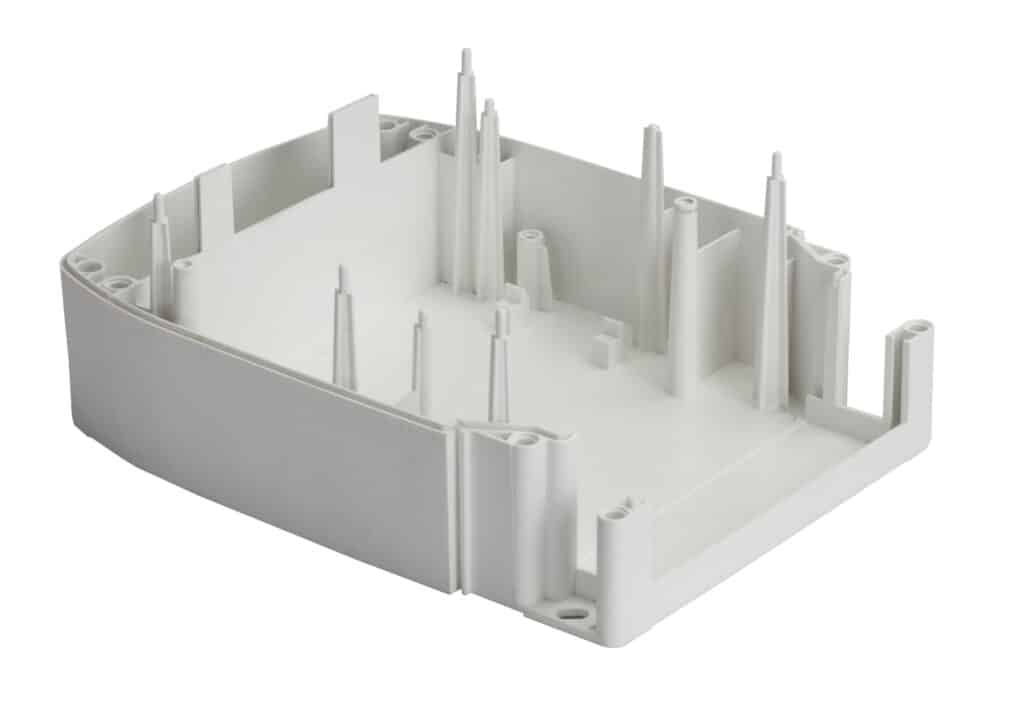

Multi-Material Molds

1. On the inner side of the injection port of the plastic injection mold, gently tap the tip of a thick copper bar against the injection port material of the injection mold. When you feel a slight movement of the material head, use a thin copper bar to get it out.

2. In order to take out the material head remaining in the injection opening of the plastic injection mold, the injection molding machine should be equipped with several thin copper bars and a thick copper bar smaller than the diameter of the injection opening to cope with any situation.

3. If the screwdriver is used to replace the copper rod, the plastic injection mold will be damaged.

4. If the residual head at the gate of the plastic injection mold cannot be pierced from the side of the injection port, heat it to red with a heater such as an iron wire and an alcohol lamp, pierce the injection port material from the side of the plastic injection mold, and clamp it with pliers after full cooling. At this time, a brass plate (or cloth strip) must be placed at the lower end of the pliers to prevent the injection mold from being damaged when the injection port material is taken out.

5. When the filler cannot be taken out with the above method, the solvent (such as acetone) of the material shall be coated on it. After the material is dissolved for a period of time, it shall be taken out slowly with a brass rod, but it shall not be close to the fire.

6. After it is taken out, the injection hole of the plastic injection mold is blown with gas, sprayed with release agent, and then the production is carried out.