Hot runner system

The hot runner is often used in our mold design. It is used more frequently in our GDM company. The hot runner system is divided into fully hot runner and semi hot runner. The design of adiabatic runner is complex, but the effect is good and the maintenance cost is very low. The micro semi hot runner is simple in structure, stable and easy to use, low in failure rate, and low in maintenance cost due to its simple structure, which can greatly ensure the stability of production.

The hot runner is used to ensure that the plastic in the runner and gate remains molten by heating. Since a heating rod and a heating ring are set near or in the center of the runner, the entire runner from the barrel outlet to the gate of the injection molding machine is in a high temperature state, so that the plastic in the runner remains molten. Generally, it is not necessary to open the runner to take out the condensate after shutdown, and it is only necessary to heat the runner to the required temperature when restarting. In short, the hot runner is the extension of the barrel of the injection molding machine.

hot runner system

The hot runner mold is a mold that uses a heating device to make the melt in the runner never solidify. Because it has shorter forming cycle than traditional dies and saves more raw materials, hot runner dies are widely used in developed countries and regions in the world.

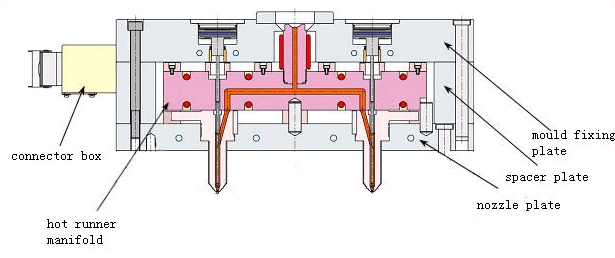

The hot runner is divided into open type (for micro semi hot runner) and needle valve type (for adiabatic runner). The hot runner system is generally composed of hot nozzle, splitter plate, temperature control box and accessories. Thermal nozzle generally includes two types: open thermal nozzle and needle valve hot runner system. The splitter plate is used when the first mock examination has multiple cavities or multi-point feeding, single point feeding, but the material level is offset. The material is usually P20 or H13. The splitter plate is generally divided into two categories: standard and non-standard. Its structure is mainly determined by the distribution of the cavity on the mold, the arrangement of the nozzle and the position of the rubber mouth. The temperature control box includes the host, cables, connectors, male and female wiring sockets, etc.

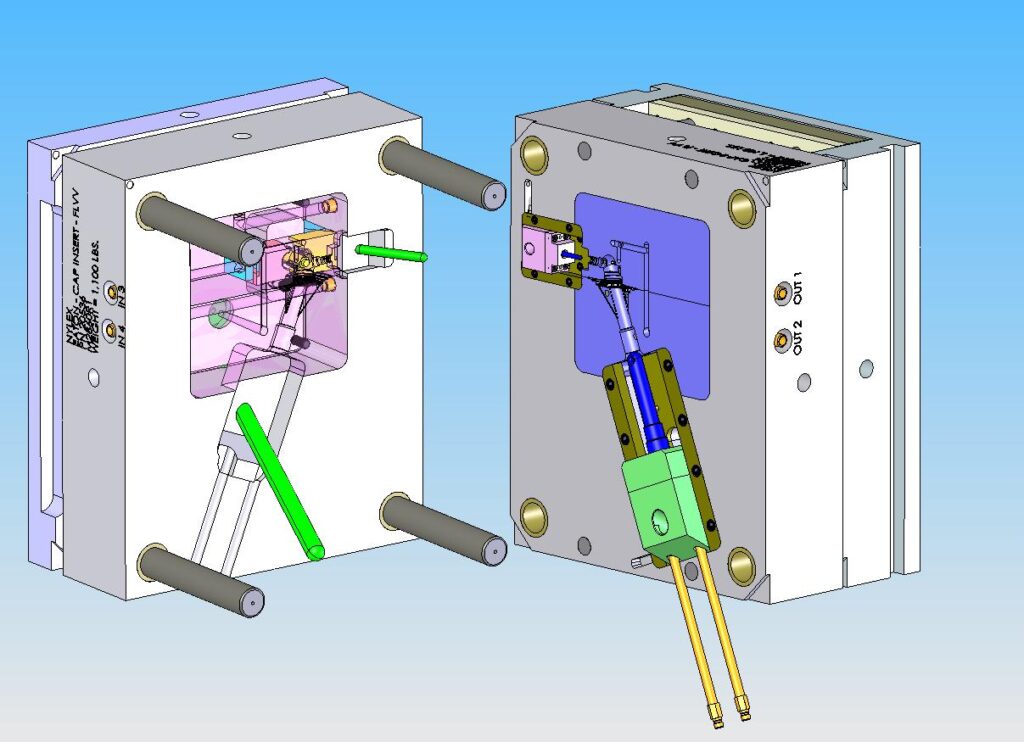

2.Structure of hot runner system

The hot runner system generally includes two types: open hot runner and needle valve hot runner.

The open hot runner is generally composed of injection nozzle, splitter plate, hot nozzle, temperature control box and accessories.

Needle valve hot runner is generally composed of injection nozzle, splitter plate, hot nozzle, temperature control box, cylinder or oil cylinder, valve needle, accessories, etc.

The nozzle form of hot runner is divided into large water inlet and sharp nozzle.

The splitter plate is used for multi cavity or multi-point feeding of the first mock examination and single point eccentric feeding. The size of the splitter plate is mainly determined by the distribution of the cavity on the mold, nozzle arrangement and gate position.

The temperature control box includes the host, cables, connectors, male and female wiring sockets, etc. Hot runner accessories usually include: heater and thermocouple, runner seal ring, connector, junction box, etc. It mainly controls the temperature of the splitter plate and the hot nozzle.

3.Advantages and disadvantages of hot runner technology

benefit

1. Save raw materials and reduce costs. (Although the cold head can still be recycled, due to the influence of human factors, mixing ratio of recycled materials, etc., in order to maintain normal operation, there must be some cold heads accumulated, resulting in the retention of funds.)

2. Shorten molding cycle and improve machine efficiency. (Because there is no restriction on the cooling time of the runner system, the parts can be ejected in time after forming and curing. The forming cycle of many thin-walled parts produced with hot runner molds can be less than 5 seconds.)

3. Improve the quality of products (During the hot runner molding process, the temperature of plastic melt is accurately controlled in the runner system. The plastic can flow into each mold cavity in a more uniform state, resulting in parts with consistent quality.)

4. Improve automation. (The plastic is the finished product after being molded by the hot runner mold. There is no need to trim the runner and recycle the cold runner. Many foreign product manufacturers combine the hot runner with automation to greatly improve the production efficiency.)

However, each technology has its own shortcomings, and hot runner technology is no exception:

1. The die structure is complex, the cost is high, and the maintenance cost is high.

2. It takes a period of time for the process to be stable when starting up, resulting in more waste products at the beginning.

3. In case of melt leakage and heating element failure, the product quality and production schedule will be greatly affected.

The third disadvantage above can be reduced by purchasing high-quality heating elements, hot runner plates and nozzles and careful maintenance during use.

4.Design procedure

First, according to the plastic structure and use requirements, determine the position of the feed inlet. As long as the plastic part structure allows, the nozzle and nozzle head in the fixed mold insert will not interfere with the forming structure, and the feeding port of the hot runner system can be placed on any position of the plastic part. The position of the feed port of conventional plastic injection molding is usually selected according to experience, and the cooling effect of each part of the mold is analyzed to determine the ideal position of the feed port.

Second, determine the nozzle head form of the hot runner system. The use characteristics of plastic part materials and products are the key factors to select the nozzle head form. The production batch of plastic parts and the manufacturing cost of molds are also important factors to select the nozzle head form.

Third, the number of cavities in each mold is determined according to the production batch of plastic parts and the tonnage of injection equipment.

Fourth, determine the mold structure size according to the plastic part structure, select the nozzle standard length series size according to the thickness size of the fixed mold insert and the fixed template, and finally trim the thickness size of the fixed template and other dimensions related to the hot runner system.

Fifth, determine the shape of the hot runner fixing plate according to the shape of the hot runner plate, arrange the power line lead slot on the plate, and design sufficient cooling water loops near the hot runner plate, nozzle and nozzle head.

Sixth, complete the design drawing of the plastic mold of the hot runner system.