How to ensure the service life of the hot runner?

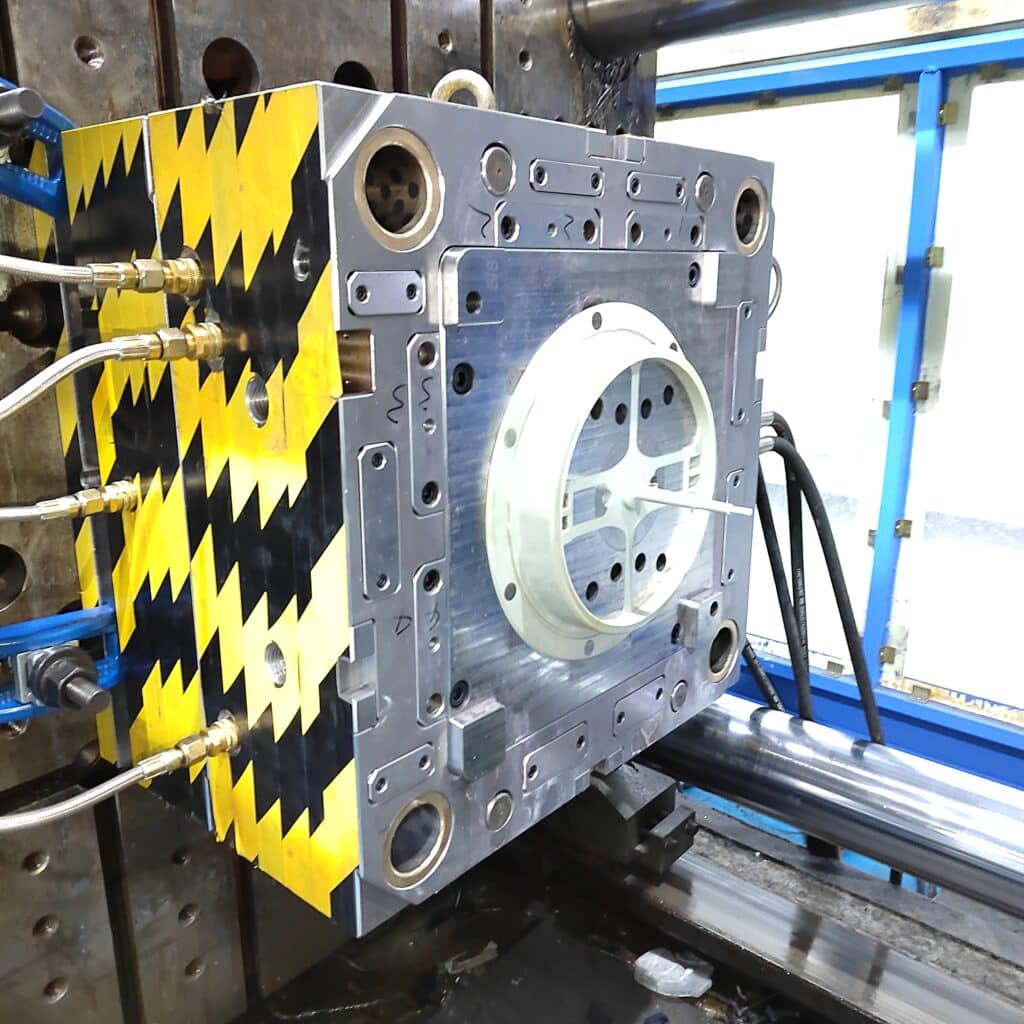

The hot channel is used in the injection mold to inject molten plastic particles into the heating part system in the mold cavity. The hot channel mold is a new structure, which heats the runner and runner of the traditional mold or three plate mold, and it is unnecessary to take out the runner and runner during each molding.

The advantages, use and precautions of hot runner can save raw materials and reduce costs. Shorten forming cycle, improve machine efficiency, improve product surface quality and mechanical properties.

1. The processing dimension accuracy of the hot runner mold cavity shall be manufactured in strict accordance with the tolerance, and the dimension accuracy of the hot runner shall also meet the tolerance, so as to ensure that the matching between the hot runner and the mold meets the requirements.

2. The deformation and strength of the formwork shall be considered as much as possible for the thickness of the formwork. According to different plastic materials, select high-quality steel with small thermal deformation, especially engineering plastics containing high fiber or high iron powder, or plastic materials with strong corrosivity, and distinguish between steel and hardness. Generally speaking, the tip of the nozzle is worn faster, followed by the passage hole of the hot nozzle. If not handled properly, the service life will be very short. Generally speaking, most people in the market are made of beryllium copper. It is certain that beryllium copper is easy to wear and has a short service life. In addition, when beryllium copper encounters PP material, PP material can dissolve a certain amount of beryllium poison, which leads to the product rich in trace highly toxic, so it should be used cautiously for medical treatment and food.

3. Do not select defective heating and temperature sensing elements. Defective components are easily damaged, unstable or ineffective. Some well-known brands of heating and temperature sensing elements can be used for 3-5 years and are very stable. Of course, the cost of hot runner will also increase.

Customers often complain about the short service life of the hot runner. There are many factors that affect the service life of the hot runner. We suggest starting from the following aspects:

(1) The machining dimension accuracy of the mold cavity of the cooperative hot runner shall be manufactured in strict accordance with the tolerance, and the dimension accuracy of the hot runner shall also meet the tolerance, so as to ensure that the matching between the hot runner and the mold meets the requirements.

(2) As far as possible, the thickness of the formwork shall be considered from the deformation and strength of the formwork. High quality steel with small thermal deformation shall be selected according to different plastic materials, especially engineering plastics containing high fiber or high iron powder, or plastic materials with strong corrosivity. Steel and hardness shall be selected separately. Generally, the tip of the nozzle is worn faster, followed by the runner hole of the hot nozzle. If it is not handled properly, the service life will be very short. Generally speaking, beryllium copper is the most widely used in the market. It is easy to wear and has a short life, which is certain. When beryllium copper meets PP material, PP material can dissolve a certain amount of beryllium poison, resulting in a product rich in trace of highly toxic. Be copper should be used with caution in medical treatment and food.

(3) Do not select defective heating and temperature sensing elements, which are easy to be damaged and appear unstable or invalid. Some well-known brands of heating and temperature sensing elements can be used for 3-5 years without damage and are stable, of course, the cost of hot runner will rise.