Several Common Injection Molding Processes for Mold Injection

Mold injection molding is used in many plastic products, and the most common process in plastic molding is mold injection molding. Plastic is a very common material in life, and the products made from it are particularly popular. What are the most common injection molding processes in the mold injection molding process?

1、 Injection molding is also called injection molding. The factors that affect the quality of injection molding are injection pressure, injection time and injection temperature.

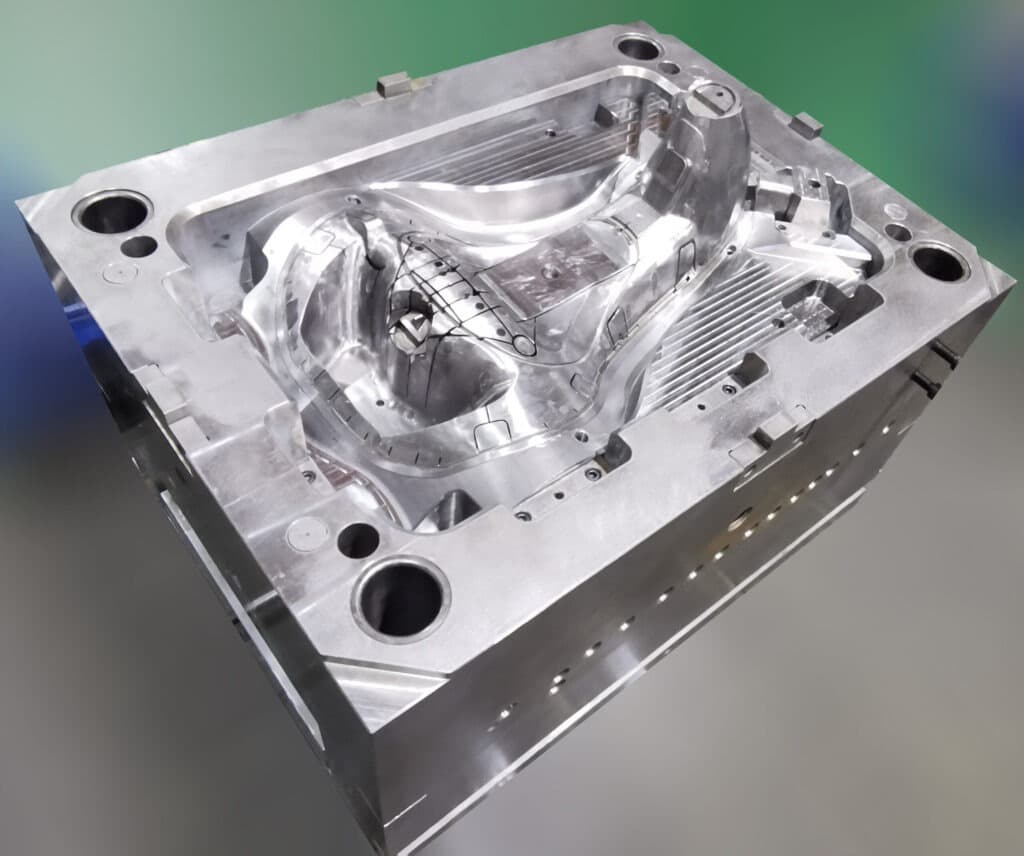

plastic injection mold

2、 Injection molding of inserts. It refers to the molding method that the injection mold is filled with pre prepared inserts made of different materials and then injected with resin, so that the molten materials can be combined with the inserts and solidified to make an integrated product.

3、 Two color injection molding. It is a special injection molding process in injection molding processing, which refers to the method of injecting two different colors of plastic into a special two-color mold to form it.

In addition, there are micro foaming injection molding process and nano injection molding process, which are commonly used in mold injection molding. They also have different characteristics and performance, but as long as the mold injection molding is through the melting raw materials, through a series of designated operations such as pressurization, injection, cooling, separation, etc., to produce a certain shape of the finished product process.