What are the problems caused by multiple mold trials?

1. If the design of the injection mold is not well reviewed, the injection structure will have unreasonable points, which makes it necessary to improve the injection mold several times after the mold trial, which not only makes the cost of the injection mold exceed the budget, but also after several improvements, people will get very unsatisfactory results.

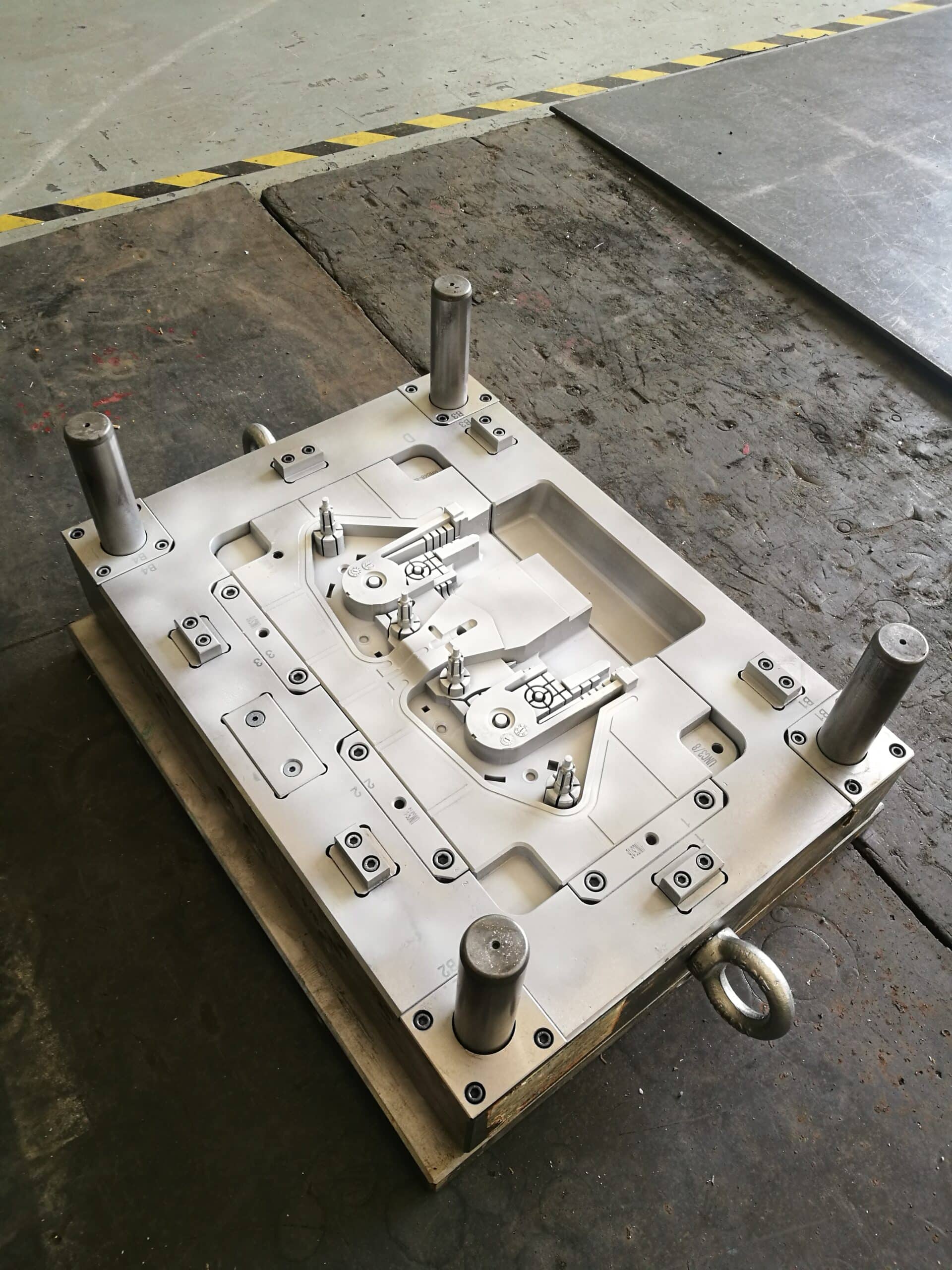

Brass Insert Molding for Auto Parts

This leads to the fact that the injection mold should be discarded and reworked. Uncontrollable cost and delayed delivery time. In some cases, the injection mold design is very good, but the large injection mold is not machined properly, which makes the number of tests increase for no reason and directly increases the cost of large injection molding. No one objects to this problem, so many large injection molding manufacturers have increased their investment in measuring equipment.

2. When testing molds, models of molding processes and injection molding machines are not selected. Obviously, the large-scale injection molding process is very good, but the injection molded product is not ideal. There is no reason to increase the number of tests, which directly increases the cost of large scale injection molding. This is a common problem in some small injection mold factories.

3. The physical properties of the plastic are not completely clear, and even the shrinkage rate is not accurate, which happens from time to time. Therefore, it is necessary to understand the physical properties of plastics before designing injection molds in order to effectively reduce the number of tests.