Advantages of insert molding

Some large mold enterprises have pursued not to insert parts at the beginning, but in the end, whether to insert parts or not should be analyzed according to specific conditions. The biggest disadvantage of the insert is that it reduces the strength of the mold itself, but it can use different materials to increase the strength of the weak parts separately.

1. Material saving:

The sizing of the rear die is determined by the highest point. If only a single piece of regular shape rises, this piece can be inlaid, so that the height can be fixed when sizing.

2. Convenient processing:

Among the processing equipment, EDM has the slowest speed and the worst accuracy. Therefore, in order to avoid EDM processing as much as possible, it is sometimes selected as the insert.

3. Convenient exhaust:

Especially in some deep bone positions, EDM processing has poor fluid discharge and poor exhaust during molding, so inserts are often required.

4. Guaranteed accuracy:

The grinding machine has the highest machining accuracy. Sometimes, in order to ensure the accuracy, it is convenient for the grinding machine to process.

5. Interchangeability requirements:

Sometimes customers require the same product, such as changing the label position, to exchange inserts.

6. Convenient die saving:

Some deep positions are inconvenient for mold saving, so they are made into inserts

7. Convenient mold modification:

Some positions are easy to wear or require too high accuracy, so inserts are made for mold modification.

8. Heat dissipation considerations:

This mainly refers to beryllium copper inserts.

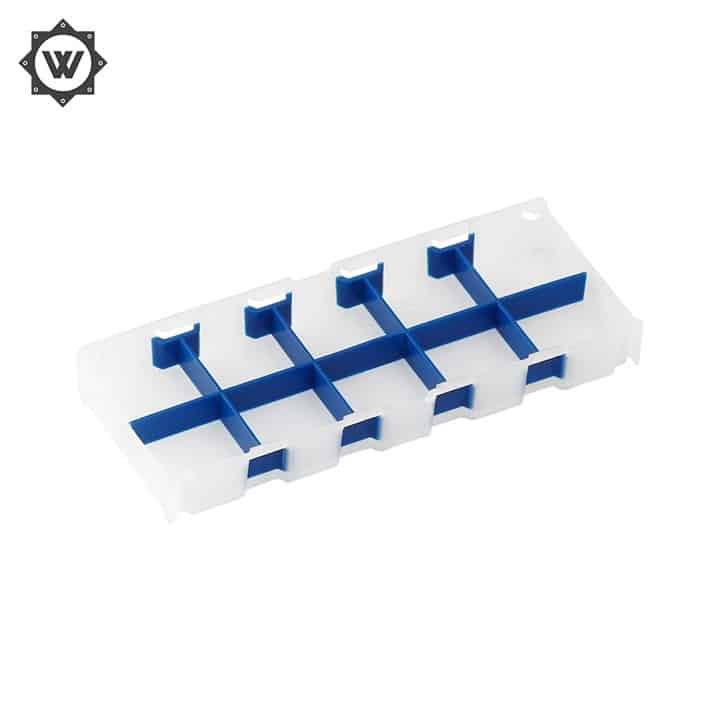

From the aspect of processing efficiency. Some large molds are inserted into small pieces and processed separately to save time. Generally, there are two kinds of inserts, through insert and blind insert. For some smaller inserts, Y-CUT line cutting can be used and hanging platform can be used for positioning. For some large inserts, such as those above 60X60, blind inserts can be used, with screws to hang them. It is relatively difficult to process, but it ensures the strength of the mold.