Analysis of the causes of shrinkage and depression of injection molded products

In the process of injection molding, shrinkage and depression of products is a relatively common phenomenon. The main reasons for this situation are.

1. Machine aspect.

(1) the injection nozzle hole is too large to cause shrinkage due to reflux of molten material, too small resistance to the amount of material is not enough to appear shrinkage.

(2) Insufficient clamping force will also cause shrinkage due to flying edge, the clamping system should be checked for problems.

(3)Insufficient plasticizing volume should be selected to use the machine with large plasticizing volume, check whether the screw and barrel are worn.

2. Mold aspect.

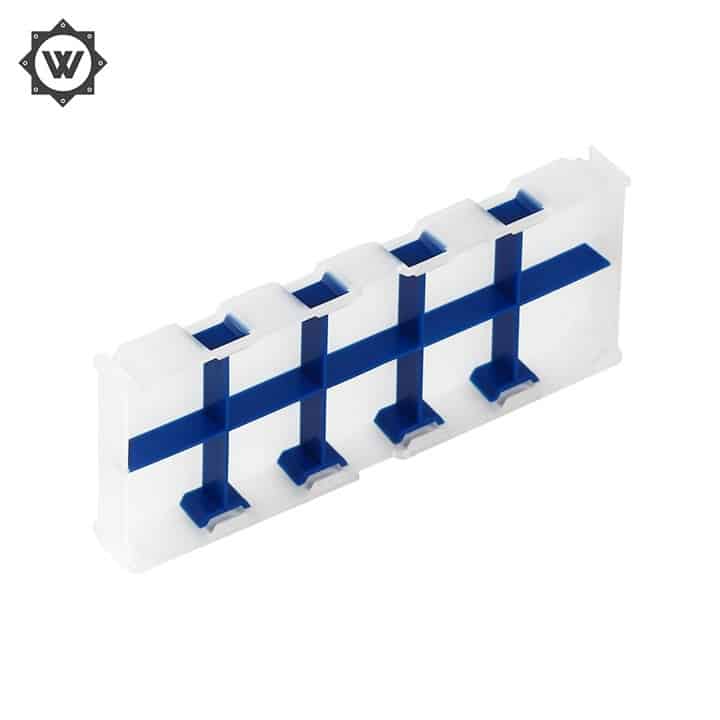

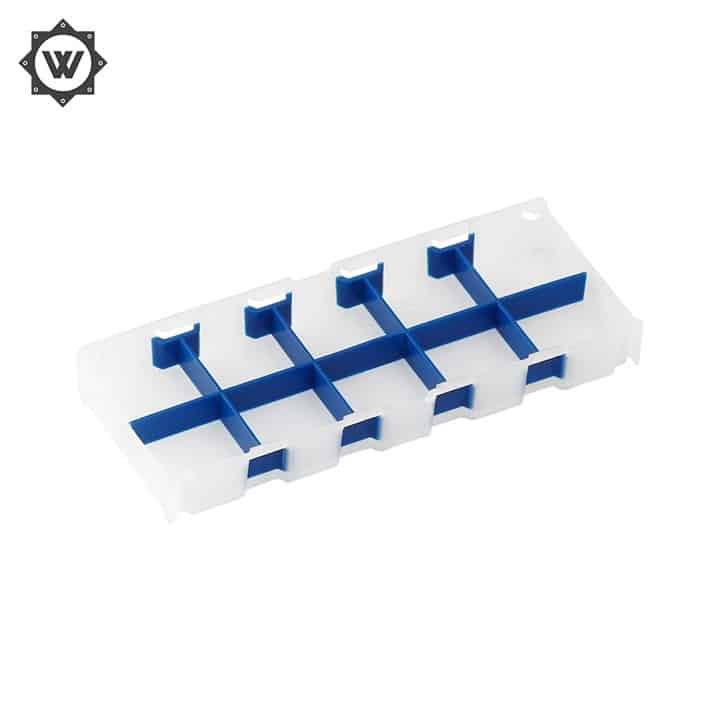

(1) The design of the parts should make the wall thickness uniform to ensure consistent shrinkage.

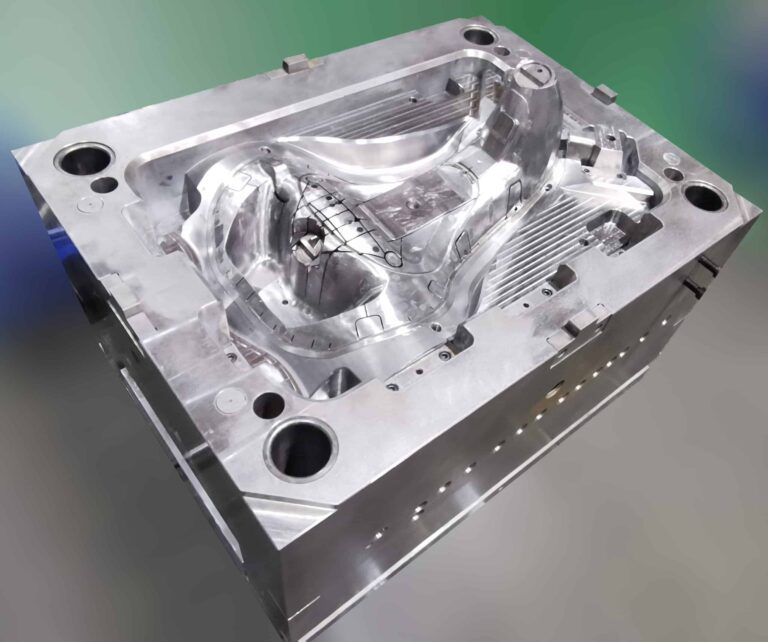

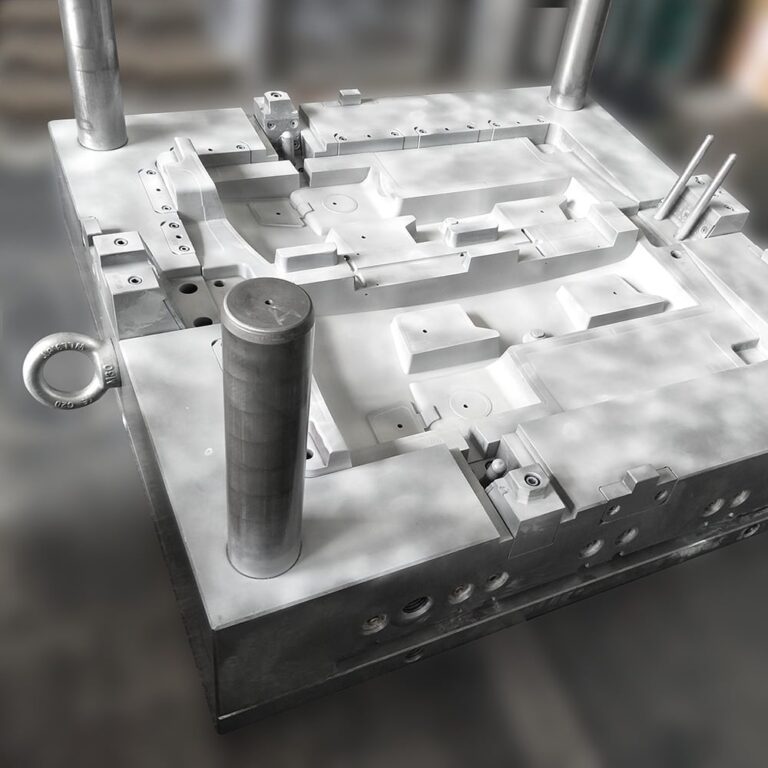

(2) The cooling and heating system of the mold should ensure that the temperature of each part is the same.

(3) The pouring system should be smooth and the resistance should not be too large, such as the main flow channel, diversion channel, gate size should be appropriate, the finish should be sufficient, and the transition area should be rounded transition.

(4) The temperature should be increased for thin parts to ensure the material flow smoothly, and the mold temperature should be reduced for thick-walled parts.

(5) The gate should be opened symmetrically, as far as possible in the thick-walled part of the part, and the volume of the cold material well should be increased.

3. Plastics.

Crystalline plastic than non-crystalline plastic shrinkage calendar, processing should be appropriate to increase the amount of material, or add into the plastic into the agent, in order to accelerate the crystallization, reduce shrinkage depression.

4. processing aspects.

(1) The barrel temperature is too high, the volume changes a lot, especially the temperature of the former furnace, the plastic with poor fluidity should be properly raised, to ensure smooth.

(2) injection pressure, speed, back pressure is too low, injection time is too short, so that the amount of material or density is not enough and shrinkage pressure, speed, back pressure is too large, too long caused by flying edge and shrinkage.

(3) The amount of material added that the buffer pad is too large when the injection pressure is consumed, too small, the amount of material is not enough.

(4) For the precision of the parts, in the injection pressure is completed, the outer layer of the basic condensation hardening and the sandwich part is still soft and can be ejected parts, early out of the mold, so that the air or hot water in the slow cooling, can make the shrinkage depression gentle and less conspicuous and does not affect the use.