Automatic insert molding system design selection considerations

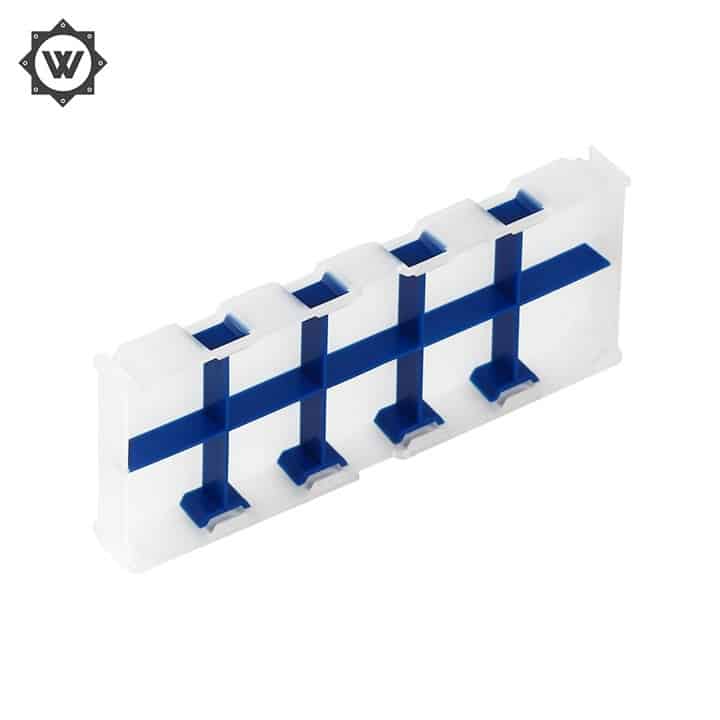

1, metal insert molding is prone to uneven molding shrinkage, prior to the shape of important parts, size accuracy limit test should be done.

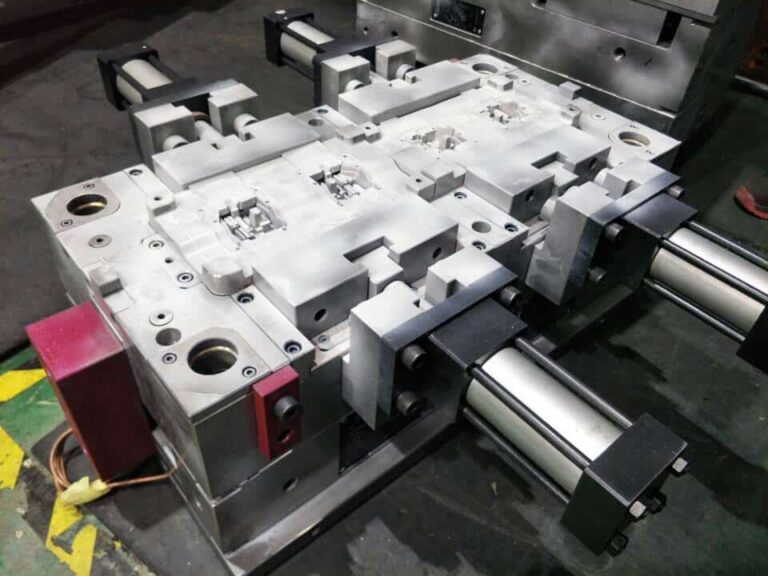

2, the injection process of metal insert is easy to deformation and displacement, should give full consideration to the mold composition and easy to maintain the shape of the metal insert mold design. For the shape of the insert can not change the injection molding process products, prior testing is indispensable.

3,In the case where the metal inserts are arranged separately and the conveyor is used, the contact between the metal inserts and between the inserts and the vibrating ball will cause slight damage to the surface of the inserts and affect the quality of the injection molded products. The quality tolerance range should be confirmed in advance.

4,The jaggedness, warpage amount, material thickness difference, diameter difference and thickness difference caused by injection processing of metal insert should be measured in advance because of stamping process. On this basis, the design of the matching selection of the automation device and the design of the mold structure should be carried out.

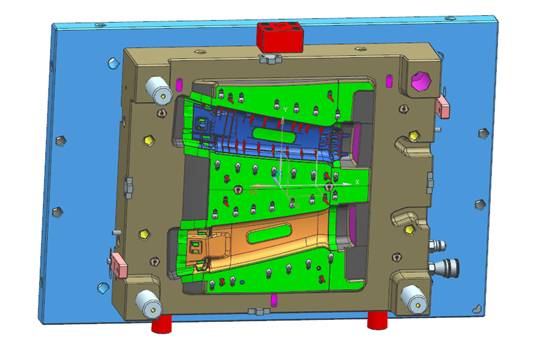

5,The predictable matters that restrict the mold structure, such as the mold gate position method and molding cycle, should be solved in advance or have corresponding corrective measures as far as possible.

6,It should be confirmed whether the metal insert needs to be preheated or dried. The purpose is to ensure the quality and stability of the injection molding process.

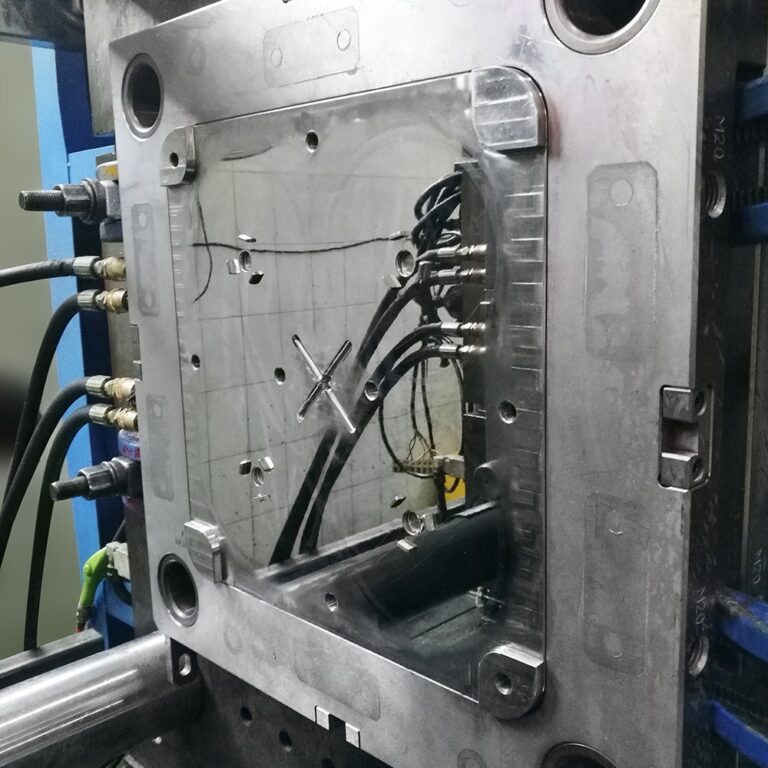

7,Injection molding process of insert molding process, various detection devices set in the mold, in order to ensure the stability of molding action under the influence of heat, force, vibration and other environmental conditions in the mold, should confirm whether to use.