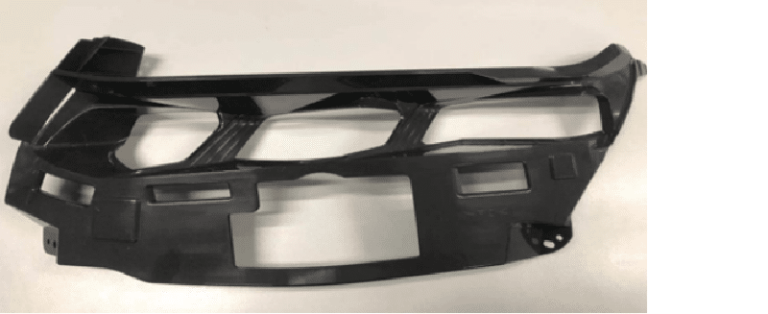

causes of silver lines in injection molded products

Silver pattern of injection molded products, including surface bubbles and internal pores. The main reason for the defect is the interference of gas (mainly water vapor, decomposition gas, solvent gas, air). The specific causes are analyzed as follows.

1. On the machine.

(1) barrel, screw wear or over rubber head, over rubber ring exist material flow dead space, long-term heat and decomposition.

(2) heating system out of control, resulting in high temperature and decomposition, should check whether the thermocouple, heating ring and other heating elements have problems. Screw design is not appropriate, resulting in individual decomposition or easy to bring in air.

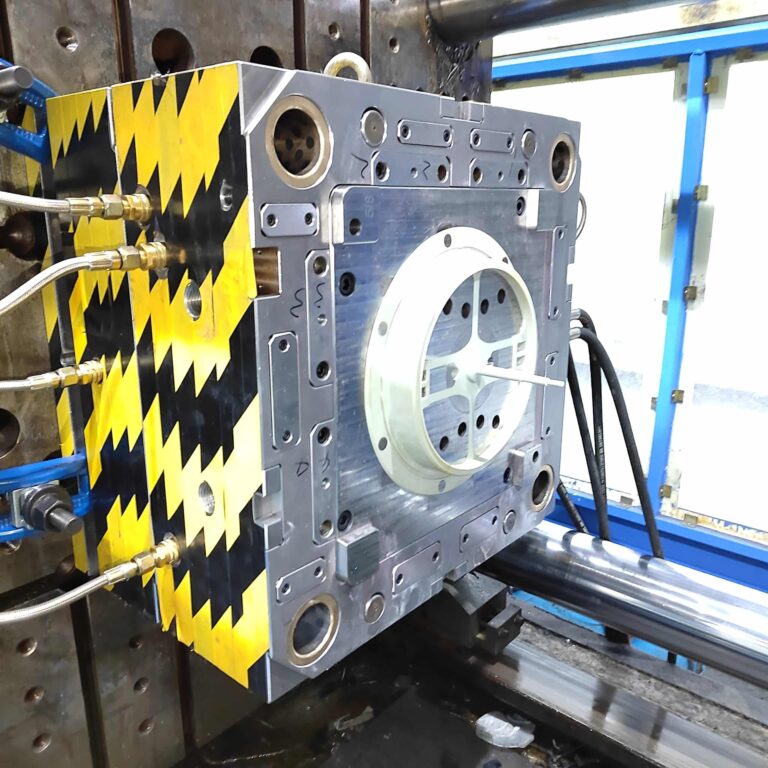

2. Mold aspects.

(1) Poor exhaust.

(2) The friction resistance of runner, gate and cavity in the mold is large, causing local overheating and decomposition.

(3)Unbalanced distribution of gate and cavity, unreasonable cooling system will cause unbalanced heating and local overheating or obstruction of air passage.

(4) Cooling pathway leakage into the cavity.

3. Plastic.

(1) plastic humidity, add too much proportion of recycled material or contain harmful crumbs (crumbs are very easy to decompose), should be fully dried plastic and eliminate crumbs.

(2) moisture absorption from the atmosphere or from the coloring agent, the coloring agent should also be dried, it is best to install a drier on the machine.

(3) The amount of lubricants, stabilizers, etc. added to the plastic is too much or unevenly mixed, or the plastic itself with volatile solvents. Mixed plastic decomposition will also occur when the degree of heat is difficult to take into account.

(4) The plastic is contaminated, mixed with other plastics.

4. Processing aspects.

(1) Set the temperature, pressure, speed, back pressure, melt motor speed is too high to cause decomposition, or pressure, speed is too low, injection time, holding pressure is not sufficient, back pressure is too low, due to failure to obtain high pressure and density is not enough to melt the gas and appear silver pattern, should set the appropriate temperature, pressure, speed and time and the use of multi-stage injection speed.

(2) Low back pressure and fast speed make the air enter the barrel and enter the mold with the molten material, and when the cycle is too long, the molten material is heated too long in the barrel and decomposition occurs.

(3)Insufficient amount of material, too large filling buffer, too low material temperature or too low mold temperature all affect the flow of material and molding pressure, prompting the generation of air bubbles.