Classification of mold rust inhibitor and rust prevention oil

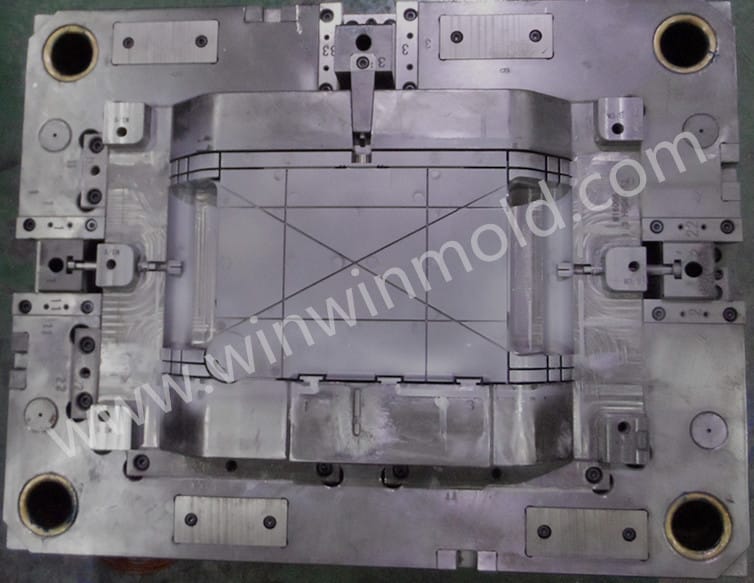

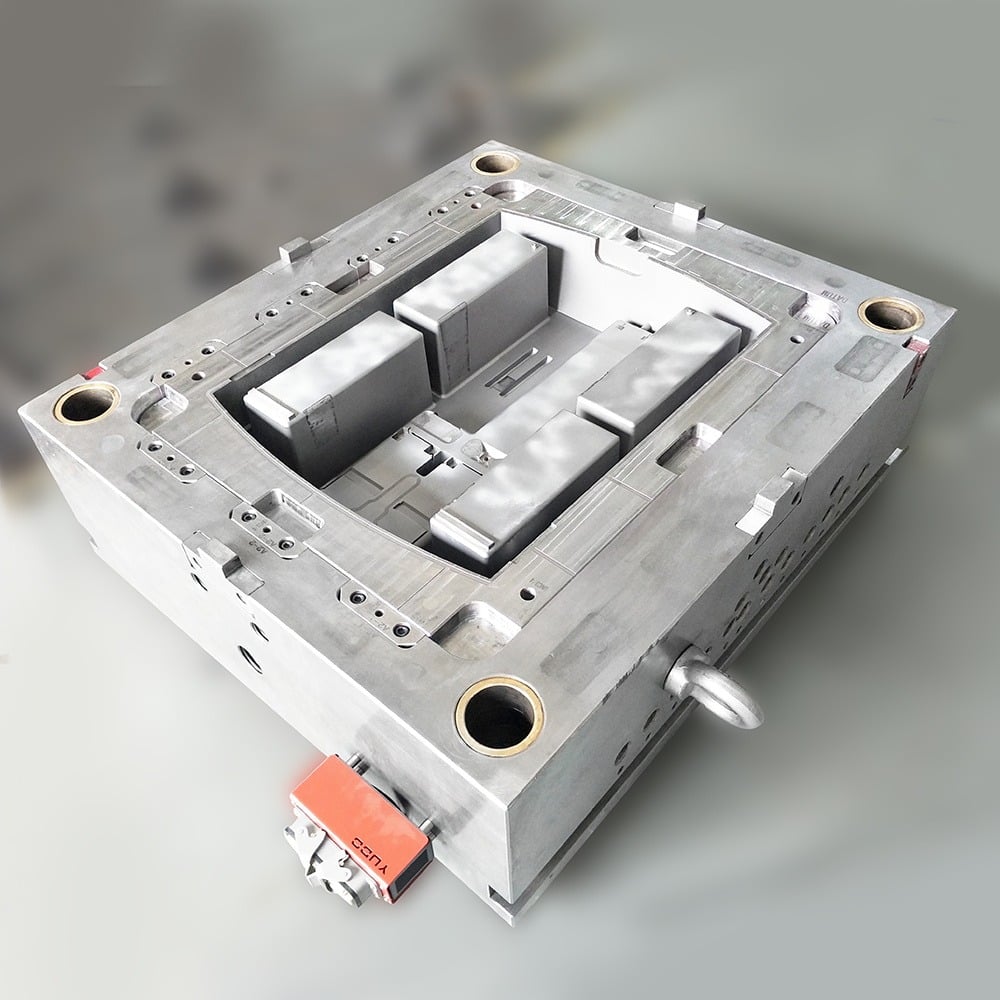

Rust prevention for molds is essential. From the smallest to the cups of daily necessities, to the manufacturing industry such as automobiles and ships. There are many manufacturers who are prone to rust in air exposure and the service life of molds is greatly shortened because of choosing the wrong anti-rust products. The reason is that there are so many types of rust inhibitors and rust prevention oils that many customers are not clear about their differences. How to choose antirust agent and antirust oil actually depends on customer requirements and production process. Choosing the right one is the most important. Then, let’s talk about the classification of rust inhibitors and rust prevention oils.

Classification of universal rust inhibitor: dry rust inhibitor, oil-based rust inhibitor, wax-based rust inhibitor, transparent rust inhibitor, etc.

Classification of universal antirust oil: wax film antirust oil, electroplating antirust oil, thin layer antirust oil, replacement type antirust oil, etc.

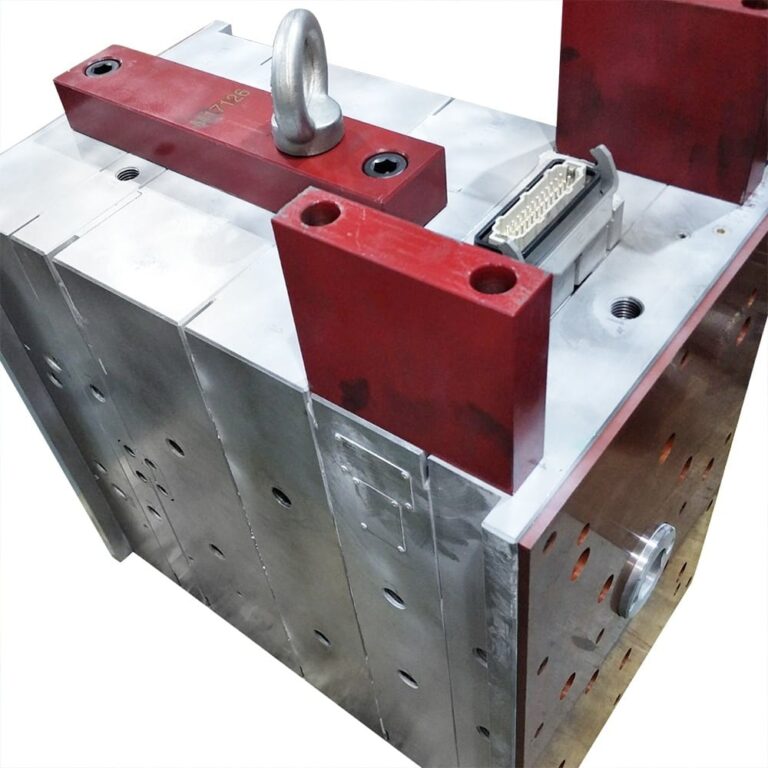

Mold just sprayed with anti-rust oil

Mold anti-rust work is very important and directly affects the service life of the mold. The anti-rust oil of injection mold has the following functions.

1. Form a protective film to resist salt spray corrosion

2. To dissolve sticky substances and loosen rusty parts

3. Lubricate and prevent rust, eliminate noise and remove water vapor

4. Dissolve dirt material, loosen rusted parts, eliminate noise, eliminate moisture, prevent moisture and corrosion, lubricate and prevent rust, etc.