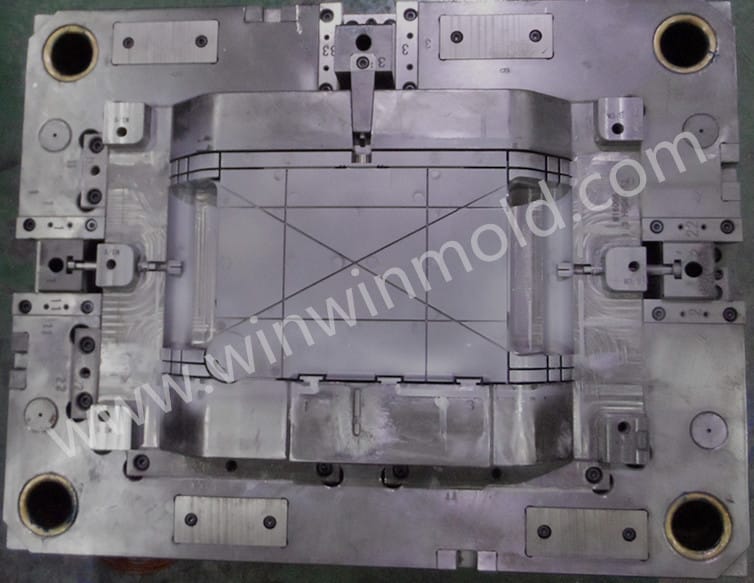

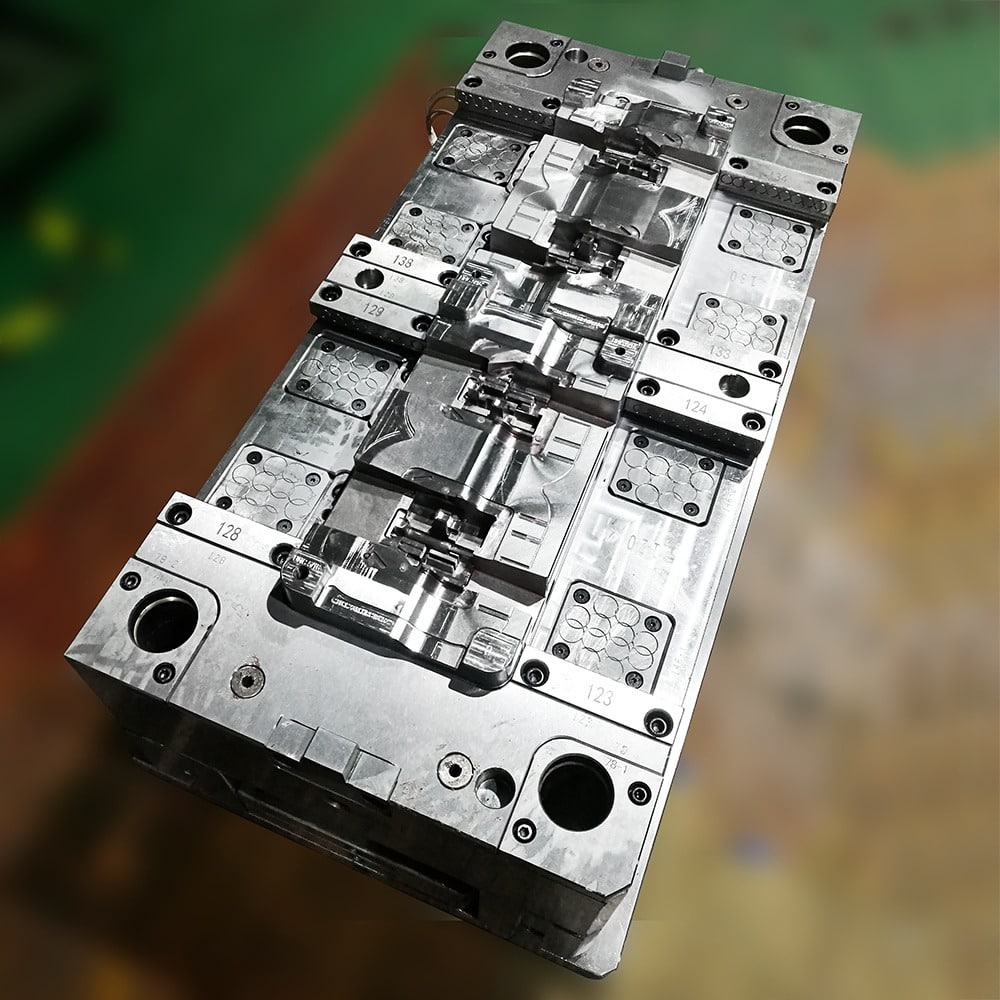

Plastic mold is a tool used in the plastic processing industry to match with plastic molding machines and give plastic products complete configuration and accurate size. According to the different molding methods, it can be divided into different mold types. It is a tool to produce industrial parts with specific shape, size, function and quality by filling plastic particles into the mold cavity through high-temperature liquefaction through the cooperation of various systems or auxiliary mechanisms in the mold. Common mold classifications can be divided into the following:

- Injection mold with single parting surface

When the mold is opened, the moving mold and the fixed mold are separated to take out the plastic part, which is called the single parting surface mold, or the double plate mold. It is the simplest and most basic form of injection mold. It can be designed into a single cavity injection mold or a multi cavity injection mold according to needs. It is the most widely used injection mold.

- Double parting surface injection molding

The double parting surface injection mold has two parting surfaces. Compared with the single parting surface injection mold, the double parting surface injection mold adds an intermediate plate (also called movable gate plate, which is equipped with gate, runner and other parts and components required by the fixed mold) that can be moved locally in the fixed mold part, so it is also called a three plate (movable template, intermediate plate, fixed template) injection mold, It is commonly used for single cavity or multi cavity injection mold with point gate feeding. When opening the mold, the intermediate plate is separated from the fixed template at a fixed distance on the guide post of the fixed template, so that the pouring system condensate can be taken out between the two templates.

The injection mold with double parting surface has complex structure, high manufacturing cost and difficult parts processing, so it is generally not used for the molding of large or oversize plastic products.

- Injection mold with side parting and core pulling mechanism

When the plastic part has side holes or side recesses, it needs to be molded with a laterally movable core or slider. After injection molding, the moving die first moves downward for a certain distance, and then the inclined section of the bent pin fixed on the fixed template forces the slider to move outward. At the same time, the push rod of the demoulding mechanism pushes the push plate to remove the plastic part from the core.

- Injection mold with movably formed parts

Due to some special structures of plastic parts, the injection mold is required to be equipped with movable forming parts, such as movable punch, movable female die, movable insert, movable thread core or ring, which can be moved out of the mold with the plastic parts during demoulding and then separated from the plastic parts.

- Injection mould with automatic thread removal

For plastic parts with threads, when automatic demoulding is required, a thread core or ring that can rotate can be set on the mold. The mold opening action or the rotating mechanism of the injection molding machine or a special transmission device can be used to drive the thread core or ring to rotate, so as to demould the plastic parts.

- Injection mould without runner

The runner free injection mold refers to the method of adiabatic heating of the convection channel to keep the plastic between the cavities of the nozzle of the injection molding machine in a molten state, so that there is no pouring system condensate when the plastic parts are taken out of the mold. The former is called adiabatic runner injection mold, and the latter is called hot runner injection mold.

- Right angle injection mold

The right angle injection mold is only applicable to the angle injection molding machine, which is different from other injection molds in that the feeding direction of this type of mold is perpendicular to the opening and closing direction during molding. The main runner is set on both sides of the parting surface of the moving and fixed mold, and its sectional area is usually unchanged, which is different from the mold used by other injection molding machines. In order to prevent the wear and deformation of the nozzle and the inlet end of the main runner of the injection molding machine, replaceable runner inserts can be set.

- Injection mold with demoulding mechanism on the fixed mold

In most injection molds, the ejection device is installed on the side of the moving mold, which is conducive to the work of the ejection device in the opening and closing system of the injection molding machine. In actual production, because some plastic parts are limited by the shape, it is better to leave the plastic parts at the side of the fixed mold for forming. This makes the plastic parts come out of the mold, so a demoulding mechanism must be set at the side of the fixed mold.