Moulds are various molds and tools used in industrial production to obtain required products by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping and other methods. In short, a mold is a tool used to shape objects. This tool is composed of various parts. Different molds are composed of different parts. It mainly realizes the processing of article shape by changing the physical state of the formed materials. It is known as the “Mother of Industry”.

2 color moldingDifferences and connections of Overmold and Two color mold

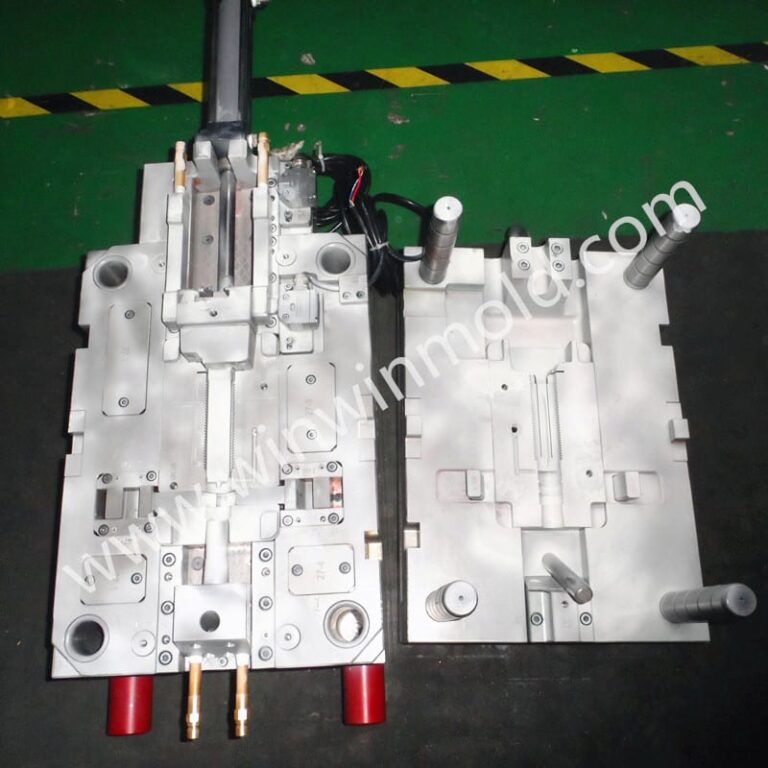

1. Overmold

Overmold is that two plastic materials are not necessarily injected on the same injection molding machine, and are molded in two times; After the product is removed from one set of molds, it is put into another set of molds for the second injection molding. Generally, this molding process is usually completed by two sets of molds, without the need for a special two-color injection molding machine.

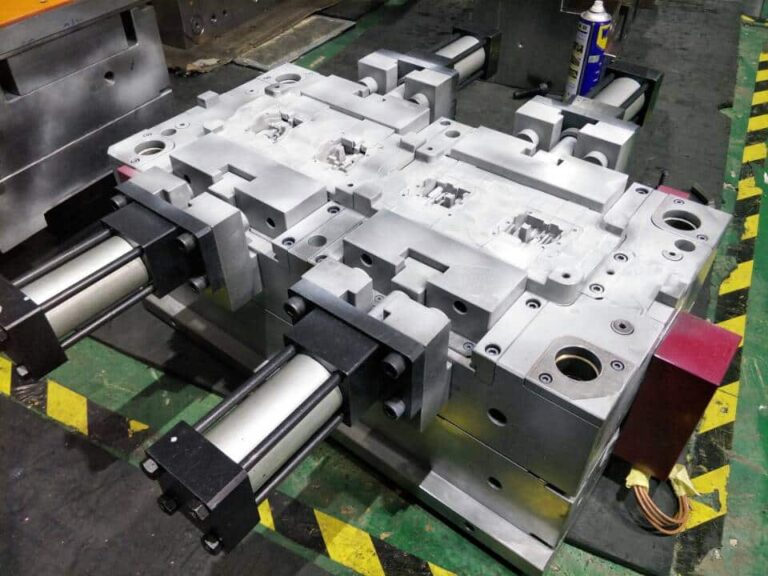

2. Two color mold

Two color mold is two kinds of plastic materials injected on the same injection molding machine in two times. There are two barrels and two nozzles. The mold has two water inlets, but the product only exits the mold once. It is usually completed by a set of molds and requires a special two-color injection molding machine.

The material processing of overmold is very similar to that of two-color mold. Whether it is a two-color mold or a overmold, usually the soft and hard plastics are used for injection molding. In 99% of cases, the hard rubber part of the product is first injected, and then the soft rubber part of the product is injected, because the soft rubber is easy to deform.