Eight common injection mold structure classification

One. Single parting surface injection mold

When the mold is opened, the movable mold and the fixed mold are separated, so as to take out the plastic parts, which is called single parting surface mold, also called double-plate mold. It is the simplest and most basic form of injection mold, which can be designed as single-cavity injection mold or multi-cavity injection mold according to the need, and is the most widely used kind of injection mold.

II. Double parting mold

Compared with the single parting surface injection mold, the double parting surface injection mold has an intermediate plate (also called movable gate plate, which is equipped with gates, runners and other parts and components required by the fixed mold) that can be moved partially in the fixed mold part, so it is also called three-plate (movable plate, intermediate plate, fixed plate) injection mold. When the mold is opened, the middle plate is separated from the fixed template on the guide pillar of the fixed mold at a fixed distance, so that the condensed material can be taken out of the pouring system between the two templates. It is not used for the molding of large or very large plastic products because of its complicated structure, high manufacturing cost and difficult parts processing.

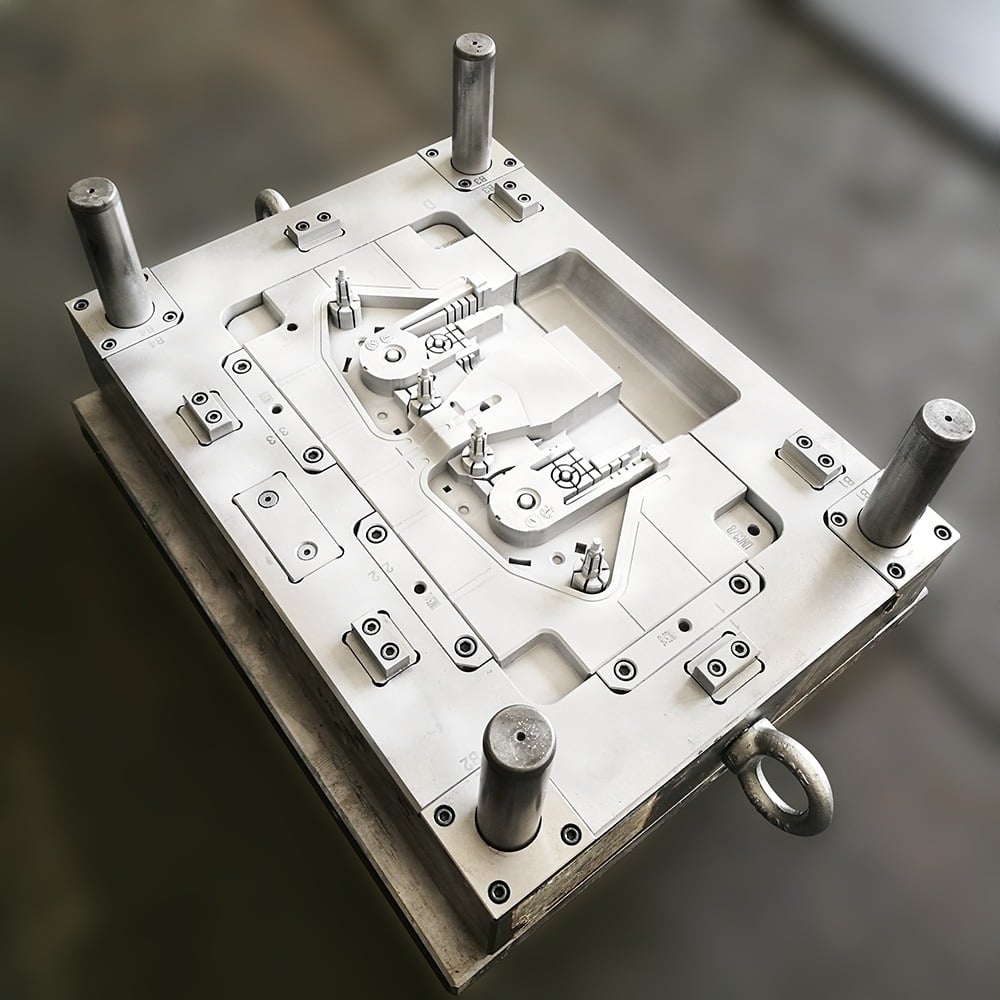

III. Injection mold with lateral parting and core extraction mechanism

When the molded part has side holes or side concave, it needs to use the core or slider that can be moved laterally. After injection molding, the movable mold first moves downward for a distance, then the beveled section of the bent pin fixed on the fixed mold plate forces the slider to move outward, while the push rod of the mold release mechanism pushes the pushing plate to make the molded part come off from the core.

IV. Injection mold with movable molded parts

Due to the special structure of plastic parts, the injection mold is required to have movable molding parts, such as movable convex mold, movable concave mold, movable insert, movable threaded core or ring, etc., which can be moved out of the mold together with the plastic parts and then separated from the plastic parts during mold release.

V. Automatic thread release injection mold

For plastic parts with threads, when automatic unmolding is required, a threaded core or ring can be set on the mold that can be rotated, and the threaded core or ring can be rotated by the opening action of the mold or the rotating mechanism of the injection molding machine, or a special transmission device can be set to drive the threaded core or ring to rotate, so as to unmold the plastic parts.

VI. Runnerless injection mold

Runnerless injection molding refers to the method of adiabatic heating of the runner to keep the plastic between the nozzle and the cavity of the injection molding machine in a molten state, so that there is no condensation of the casting system when the mold is opened and the part is removed. The former is called adiabatic runner injection mold, and the latter is called hot runner injection mold.

VII. Right-angle injection mold

The right-angle injection mold is only applicable to the angle injection molding machine, which is very different from other injection molds in that the direction of feeding is perpendicular to the opening and closing direction. The main channel is opened on both sides of the parting surface of the moving and fixed mold, and its cross-sectional area is usually unchanged, which is different from other molds for injection molding machines.

VIII. Injection mold with the release mechanism on the fixed mold

In most of the injection molds, the mold release mechanism is installed on the side of the moving mold, which is conducive to the work of the ejector in the mold opening and closing system of the injection molding machine. In actual production, due to the shape limitation of some plastic parts, it is better to leave the plastic parts on the fixed mold side for molding.