Essential skills for plastic mold repair personnel

As we all know, with the accumulation of mold production times on site, mold life is a process of gradual decline, from running in of new mold to normal production to the end of life.

When the new mold is produced in small quantities, some problems may be exposed. Whether the mold design is reasonable and the mold processing precision meets the product requirements, the mold manufacturer will make certain adjustments to the mold. Once the mold has been adjusted and the production is stable, many problems often occur, then the probability will be relatively small.

As for the later stage of mold production, after a long period of high pressure mold locking and high temperature and high pressure impact of the melt, the wear and deformation of the mold can not obtain acceptable size and good appearance, and finally can not be repaired or can not meet the original precision size or appearance requirements after repair, which is understandable.

As a qualified die repairer, every die will be integrated into his world. What has happened to the die and how to repair it? There is nothing better than him. If you are a model repairman and do not have certain skills and judgment, why do you put your foot in the mold? So we need to master some necessary skills,

It can be summarized as follows: master the skills of mold knowledge, plastic injection molding knowledge, measuring tool use, and mold repair related machine operation. Only by knowing oneself and the enemy can we win every battle.

Find problems and have the courage to find the root cause of problems. The production site should also actively cooperate, think more together and draw on the wisdom of the masses, which is conducive to solving the problem. If there is a problem, it is not adjusted properly on site, or if there is a problem, it is not correct. What is the basis for saying that the on-site process is not well adjusted? What is the basis for saying that the mold is defective?

There are many possible factors that may cause product defects, which need to be patiently eliminated one by one. Unless it is very intuitive, you can see what the problem is at a glance, for example, the inlet on the mold is broken. Another example is the product burning problem. This is a mold with the parting surface through the exhaust slot, and the cumulative production has exceeded 800000 mold times. It is reasonable that poor exhaust will not occur, and the on-site shooting speed has also been slowed down, but it is still not good.

Remove the die core and measure the exhaust port with a calibration meter. As the die is frequently locked for production, the depth of the exhaust port on the parting surface is almost gone. Therefore, we should not have habitual thinking. The existence of exhaust on the mold does not guarantee its good exhaust performance all the time. It may also be that the exhaust port is blocked by plastic decomposition products.

Therefore, the mold repair personnel should have a certain judgment ability, just like judging a case, and only when the judgment is accurate can they go on the right path. Wrong judgment will make the target deviate from the direction, resulting in twice the effort and half the result.

1.Skills to master mold knowledge

1.1 Mold structure and material

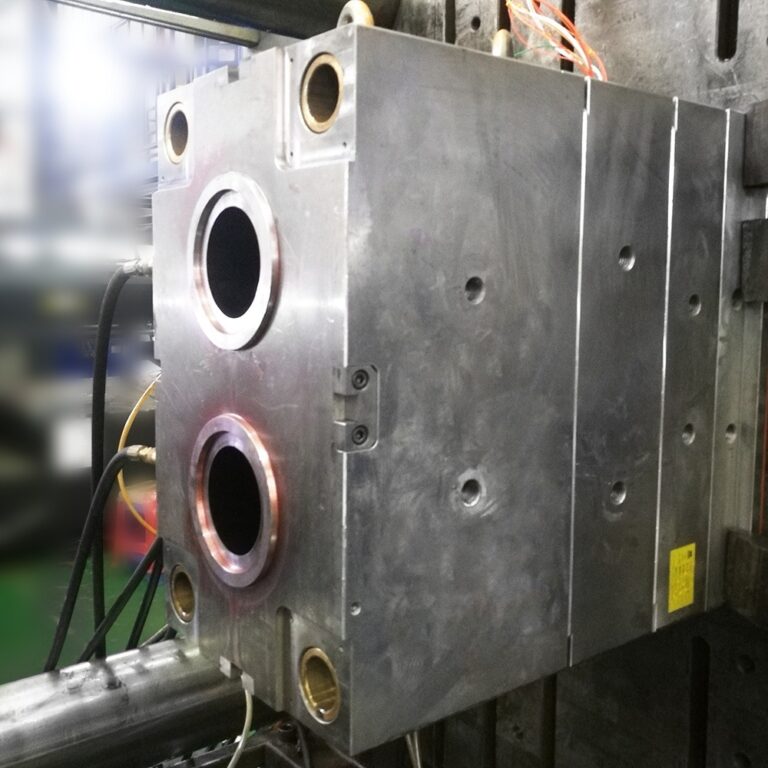

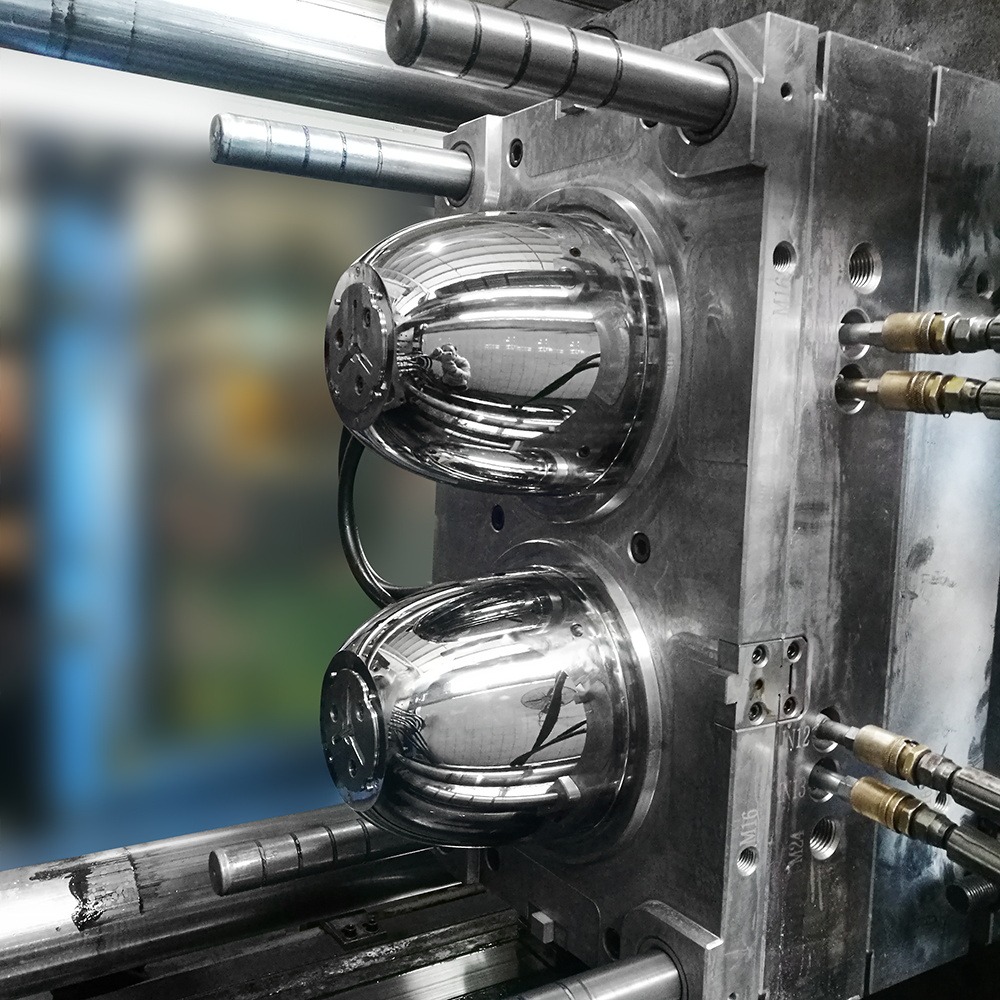

For a die repairer, it is necessary to know clearly before disassembling and assembling a pair of dies, which is related to the sequence of die disassembly. What is a two plate mold, what is a three plate mold, and what is a hot runner mold. If you don’t know its structure, how do you do it? So we should know the theoretical things. What kind of material is suitable for what kind of occasions, which should take into account the economy and applicability of the mold.

1.2Functions of various parts of the mold

The role of mold parts is related to the use of mold parts in the mold. Each mold part on the mold has its meaning of existence, and does not exist for no reason. What plays a positioning role, what plays a guiding role… Think about it: what will happen if this part is missing or damaged on the mold?

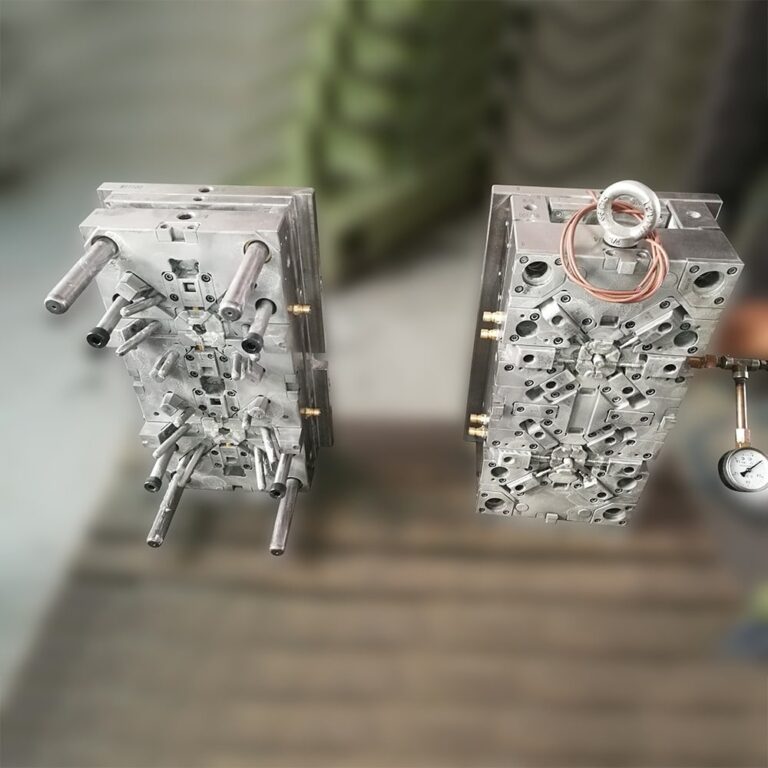

1.3Operation sequence and principle of mould

What actions are performed first, then what, and then what. If there is no action sequence or action together, it indicates that the mold has had a bad condition. Such as the action sequence of secondary ejection, thread demoulding mechanism, sliding block cylinder core pulling, etc.

1.4Mold surface

If the drawing is not clear, how to repair the damaged mold. Mold repair personnel should not only be able to understand the drawing, but also be able to know the fitting tolerance and accuracy requirements of mold parts.

2.Skills to master injection molding knowledge

What are the flash, scratch, flow mark, scorch, short shot, money, etc. of the product, and how do they come into being? What is the impact of the adjustment of process parameter values such as pressure, injection rate, material temperature, pressure holding and back pressure on product quality? You may not be able to adjust the machine, but these processes related to molds are also the knowledge you must master.

The so-called “seven parts mold, three parts process” shows the importance of mold. In fact, mold and process are indispensable for producing a qualified product. The purpose of mastering injection molding knowledge is to enable repair personnel to distinguish what is caused by the mold and what is caused by improper process.

For example, for the flash of the product, the first thing that the repair personnel think about is whether there is any product or foreign matter pressed into the mold, the second is whether the mold fitting clearance is too large (wear and surface collapse deformation), and the last is whether the injection pressure is too large, whether the injection rate is too fast, whether the material temperature is too high, or whether the stand cylinder is broken (use the exclusion method to exclude one by one).

Observe the mold on the bench against the product. If it is confirmed that it is not caused by the mold, the production site shall be notified to adjust the process parameters. If the repair personnel themselves are not very clear about the process knowledge, they cannot explain to the production site and give solutions. The production site personnel knew little about the mold, but the mold repair personnel handled the mold well, and the rest could only be solved by the process. Finally, there was no way but the quality assurance personnel to confirm whether they were allowed to accept.

3.Master the use skills of measuring tools

For example, calipers, micrometers, height gauges, depth gauges, calibration gauges, projectors, etc., should be able to use them skillfully. What measurement tools are used under what circumstances.

For example, after the insert on the mold is damaged, first look for the computer drawing file. Take the drawing file as a reference, and measure the intact inserts on the mold as the dimension basis for processing the new inserts. The drawing cannot be trusted completely. I encountered many discrepancies between the drawing and the real object in my work, which led to errors in processing parts. Some new parts can only be replaced after being measured and confirmed by measuring tools (if the size of new parts does not conform, they need to be re processed in place). Therefore, mastering the use skills of measuring tools is the most basic skill for mold repair personnel.

4.Operating skills of machine related to mold repair

4.1Grinding machine processing

After the mold is damaged, some small parts need to be repaired by welding. The welding to the mold core or into the sub surface can be ground by the grinder (including the actual matching of new parts, with large peripheral dimensions). When the amount of welding repair is small, grinding is definitely the fastest way.

Be familiar with the knowledge and operation related to the grinder, how to load and unload the grinding wheel, the tool setting and feed mode of the grinding wheel, the application scope of the grinding wheel, the correction of the balance of the grinding wheel, the clamping and fixing of the workpiece, etc. As for the correction of grinding wheel balance, some companies do not pay attention to it, which is not standardized.

4.2Dust collecting grinder operation

Dust collecting grinder is used for rough grinding of parts. For example, if the amount higher than the surface of the part after argon welding is too large, the shape of the part can be roughly polished by holding the part.

4.3Milling machine or rotary drilling machine

Simple operation, if a screw is broken on the mold. Re drill a hole on the original foundation and take out the broken screw. For example, two threaded holes are machined due to the lack of sensor fixing on the mold. On the three plate die, the grab pin of the stripper plate is worn through the hole and reamed after enlarging the hole.

Be familiar with the knowledge and operation of milling machine or rotary drilling machine, the selection of drill bit and tapping, the selection of rotating speed, the clamping and fixing of workpiece, etc.

4.4EDM

After the die is damaged, the electric discharge machining will be used after welding. The electrode is used to conduct electric discharge machining on the welding repair part of the die. (Parts that cannot be repaired by manual repair, such as deep and narrow grooves or curved surfaces)

4.5Ejector processing of precision cutting machine

If the thimble on the mold is broken or worn, a new thimble with the same specification needs to be replaced and processed, and a precision cutting machine will be used. It should be the simplest thing to process the length of a thimble.

Without precision cutting machine, grinding machine and grinder may be used or fast wire cutting may be used. Be familiar with the removal and replacement of grinding wheel cutting pieces, the clamping of thimbles, the use of jigs, etc.

4.6Polishing Grinder Operation

Some parts in the mold cavity have a large amount of weld repair. First, use the polishing machine to hold the grinding rod to rough trim the spots, and then use the electrode for electrical discharge machining. If there is no electrode and no drawing, some parts can only be manually repaired by the polishing machine.

4.7Punch forming and machining

Punch forming machine is used to grind the cylindrical part’s cylindrical shape. If the grab pin of the three plate die on the die is broken or the forming pin is deformed, the punch forming machine can be used.

4.8Argon welding or laser welding repair

The damage of mold parts is nothing more than welding repair, insert and re preparation treatment. Argon welding and laser welding have their own advantages. Many die repairs will be equipped with argon welding machines, but few will have laser welding repair machines. If die repairs can be repaired by argon welding or laser welding without going out for argon welding or laser welding, the time and cost of die repair can be greatly reduced.

4.9Manual polishing

Some small barbs or collapses of the mold, causing scratches or strains on the product appearance. Or there are bad marks and rust spots on the mold, which affect the product surface. Then the mold repair personnel must master the polishing actions of diamond paste, sandpaper and oilstone.

Sometimes a file may be used. A file is a manual skill, and it is difficult to master the skills of file repairing mold without a certain amount of time. In the absence of adequate equipment and conditions, sometimes only rely on manual skills to make up for it.

4.10Mold maintenance

After or during mold production, it is necessary to clean and wipe the parting surface, oil the guide post and slide block, and perform a series of cleaning and spot check actions. Mold maintenance is the basic skill of mold repair personnel, which can be easily disassembled, cleaned, oiled and maintained.

4.11Some tips related to moulds

How to quickly and effectively take out broken screws, broken water pipe joints, how to use jigs or fixtures to process some small parts on the mold, how to remove the mold more conveniently, and so on.

The more skills and knowledge mold repair personnel have, the more conducive to the rapid development of mold repair work, more handy, and can greatly shorten the mold repair time, so the corresponding requirements for mold repair personnel are high. Some people may say that lathe machining, CNC machining center, wire cutting are all available. Isn’t it more conducive to mold repair? Of course, “more technology does not press the body”. Mold repair has the characteristics of mold repair, which is different from mold opening to a certain extent.

Mold repair skills are on the one hand, and on the other hand, mold repair personnel need to have the ability to find problems and think independently and solve them independently, which is more conducive to personal growth and reflects personal value.