Factors Affecting Plastic Loss Rate in Injection Molding Process

For injection molding plants, the plastic loss rate in the injection molding process is directly related to the production efficiency of enterprises. What are the factors that affect the plastic loss rate in the injection molding process?

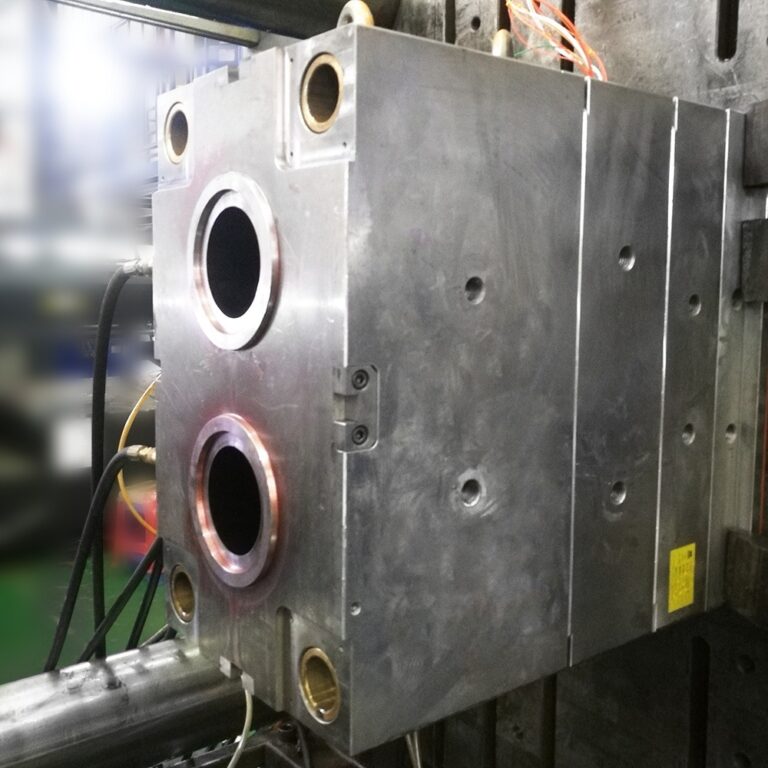

1: When replacing the injection mold, if the injection mold is changing production

It is easy to increase the plastic loss rate, so it is very important for injection molding operators to master the extrusion speed of injection molding plastics when replacing injection molds. A professional injection molding master can save a lot of plastic in this detail every year, which directly saves unnecessary plastic procurement costs.

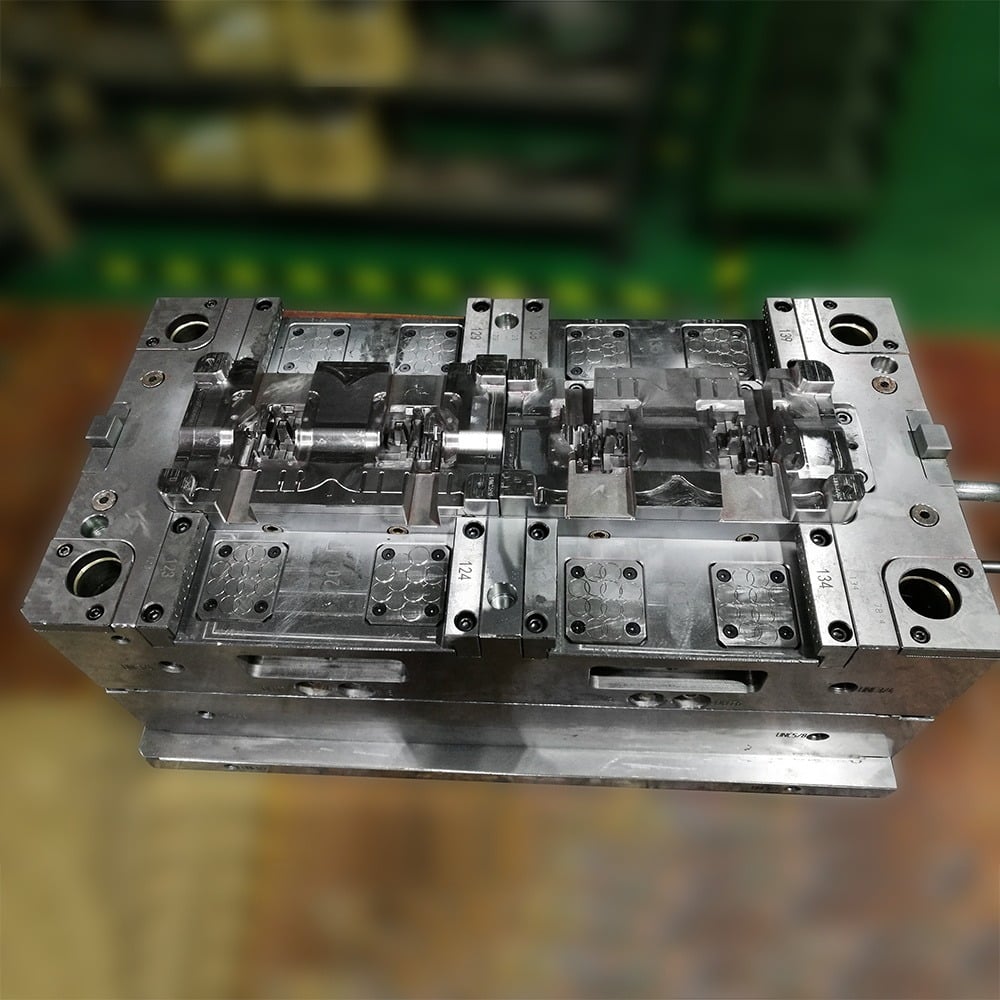

2: Products with strict requirements for injection molded appearance parts

For plastic injection products with high plastic loss rate, if the requirements for color, appearance and precision are relatively high, the plastic loss rate is often high. At this time, the mixing amount of the nozzle is relatively small, and more nozzles are mixed inside, so the plastic loss rate will be reduced a lot.

No matter what injection molded parts are processed, the reasons for losses must be considered in advance before production to avoid insufficient injection molded products and affecting the production efficiency of the injection molding plant.