General price of injection molding

There are many injection molded products, such as disposable cups, disposable lunch boxes, mobile phone shells, bags, flower plates, and some electronic products. These products are often used in our daily life. And as long as a mold is changed, the injection molding machine can make products of different styles and shapes. What is the opening price of our injection mold? What is the price of injection mold?

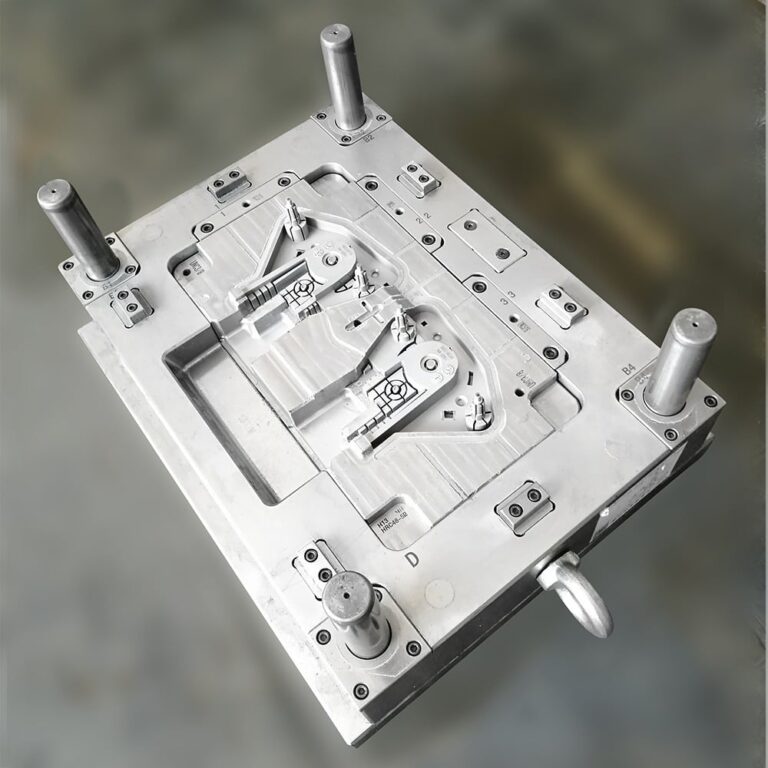

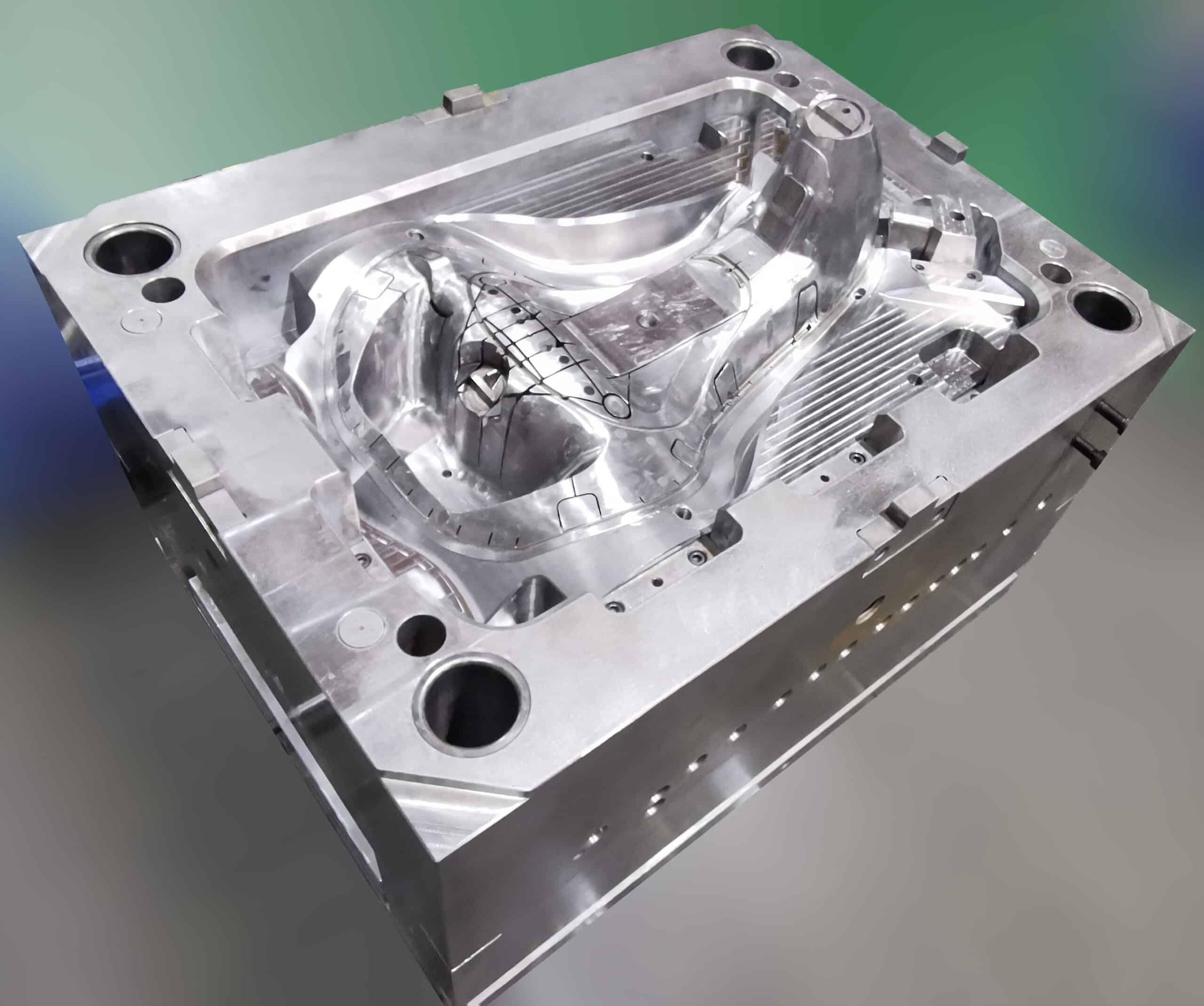

The mold is generally charged by set, and the opening cost is generally how much. Generally, the price should be discussed according to the following points: 1. the size (or tonnage) of the mold 2. the material used for the mold 3. the mold design 4. the mold assembly (sometimes including the mold test status); Mold price=material cost+design cost+processing cost and profit+VAT+mold trial cost+packaging and transportation cost; Or according to the complexity of the mold, plastic mold=6~10 * material cost.

If the injection mold is a simple container mold, thousands of yuan is enough. If it is complicated, it may be expensive. There is no upper limit. It may be hundreds of thousands or millions.

Mold is required for the production of injection molding products. Mold pair is a tool used to determine the shape and exact size of the product. The mold opening of the injection molding machine needs to be done according to the product size, model and shape provided by the customer. After the mold is opened, it needs to be adjusted several times until it fully meets the standard and is delivered to the customer without problems.

The application scope of plastic products is expanding, and the consumption of plastic products is also rising. In plastic processing, the mold is matched with the plastic molding machine. Because of the types and processing methods of plastics, the structures of plastic molding machines and plastic products are complex and simple, so the types and structures of plastic molds are also diverse. In addition, since the development of the mold industry, there have been many intelligent mold products, which can achieve high efficiency and energy saving through machine control and digital management.