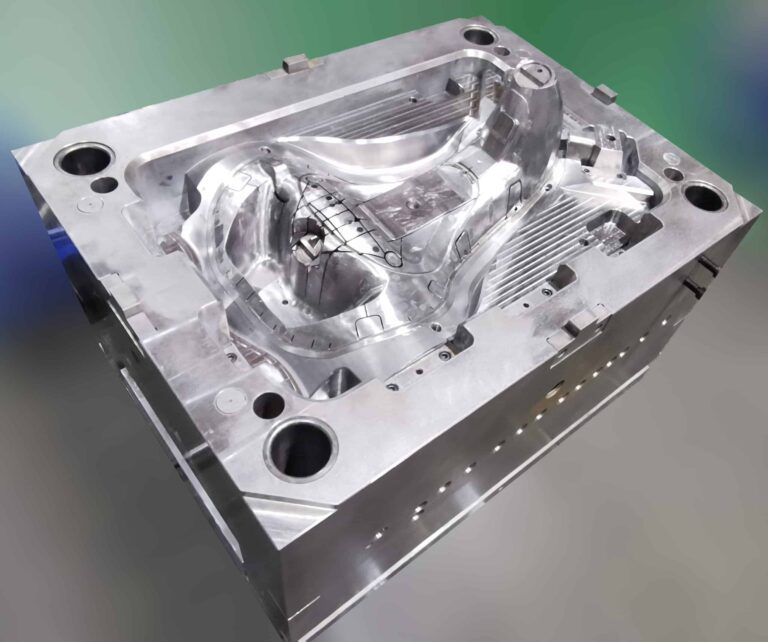

General process of mold design

American industry believes that “mold industry is the cornerstone of American industry”; Germany regards it as a “key industry” among all industries; Japan Mold Association also believes that “mold is the power to promote social prosperity and prosperity”, is also “the secret of the entire industrial development”, and is “the driving force to enter a rich society”.

General process of mold design:

<1> Analyze and digest the products and samples

<2> It should be understood whether the customer has requirements for the specification of the injection molding machine to determine the size range of the mold

<3> Determine the number of cavities and arrange them

<4> Determination of parting surface

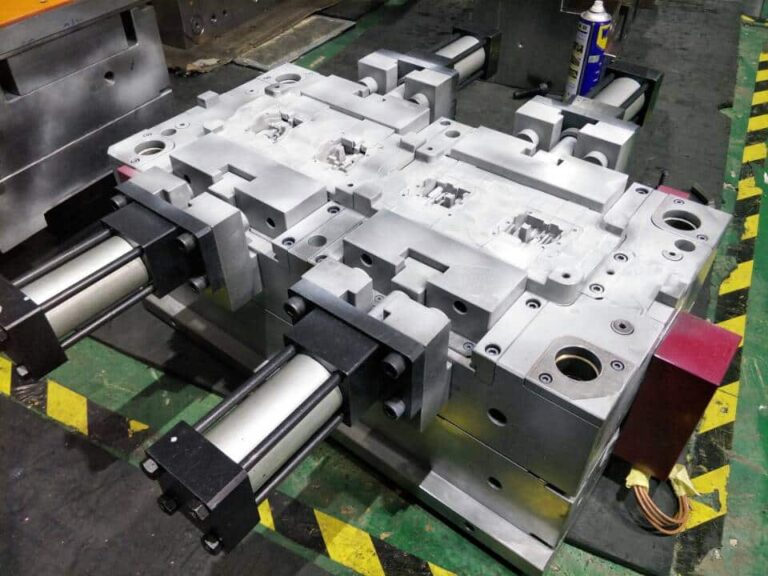

<5> If there are rows and oblique structures, you should first understand them

<6> Gating system design

<7> Determination of mosaic structure

<8> Ejection and reset system design

<9> Cooling and heating system design

<10> Guide. Positioning device

<11> Determine the mold and select standard parts

<12> Die steel selection

<13> Complete the structure drawing, mold drawing and blanking

<14> Print, check and submit the drawing to the mold design team leader and supervisor