How are injection molded products formed?

An injection mold is a hollow block of metal into which molten plastic is injected to form a specific shape. The injection mold is drilled with many holes for temperature control through hot water, oil or heaters to ensure perfect molding of the injection molded part.

The molten plastic flows into the mold through the gate and fills the cavity through the runners and gates. The mold is then opened after cooling and the top bar of the injection molding machine then pushes the top plate of the mold to eject the mold.

The injection molded product consists of a gate to introduce the molten resin, a runner to guide the molten resin into the cavity, and the final product.

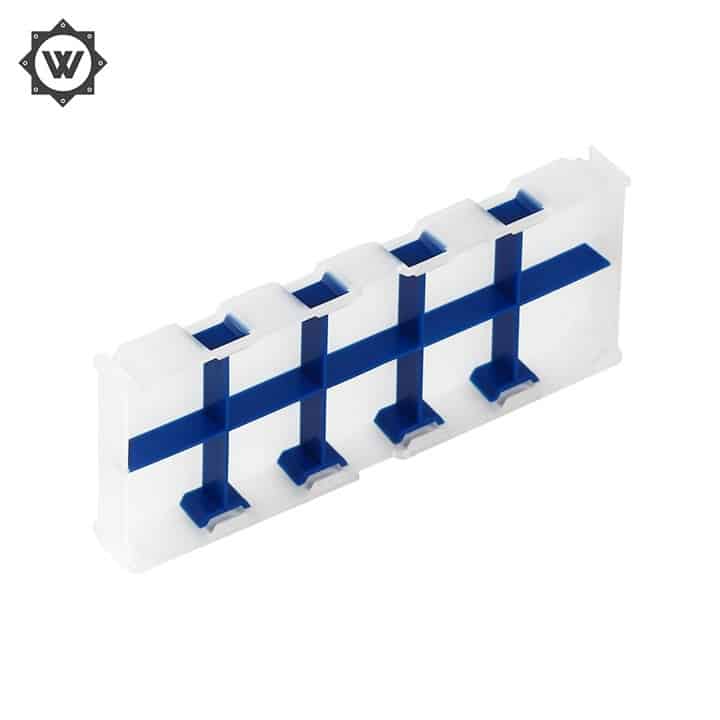

If only one product is produced in a single injection, the efficiency is very low. Therefore, injection molds are often designed with multiple cavities so that multiple products can be produced in a single shot. In addition, in a mold with multiple cavities, the distance between two cavities and the gate is usually equal. Otherwise, it is easy to have one side filled and one side unfilled.