How can plastic mold manufacturers effectively improve production efficiency?

In the era of rapid development of industrialization, how to improve the production efficiency, shorten the development cycle, improve the technical level of plastic mold, reduce production costs and other factors is undoubtedly a problem faced by plastic mold factories at this stage.

1. Implement concurrent engineering throughout the process.

The whole process of concurrent engineering is one of the most effective ways to shorten the development cycle of plastic mold. The so-called concurrent engineering is that all processes in the plastic mold development process should be synchronized, parallel and crossed. Try to avoid serial.

2. Standardized design and manufacturing

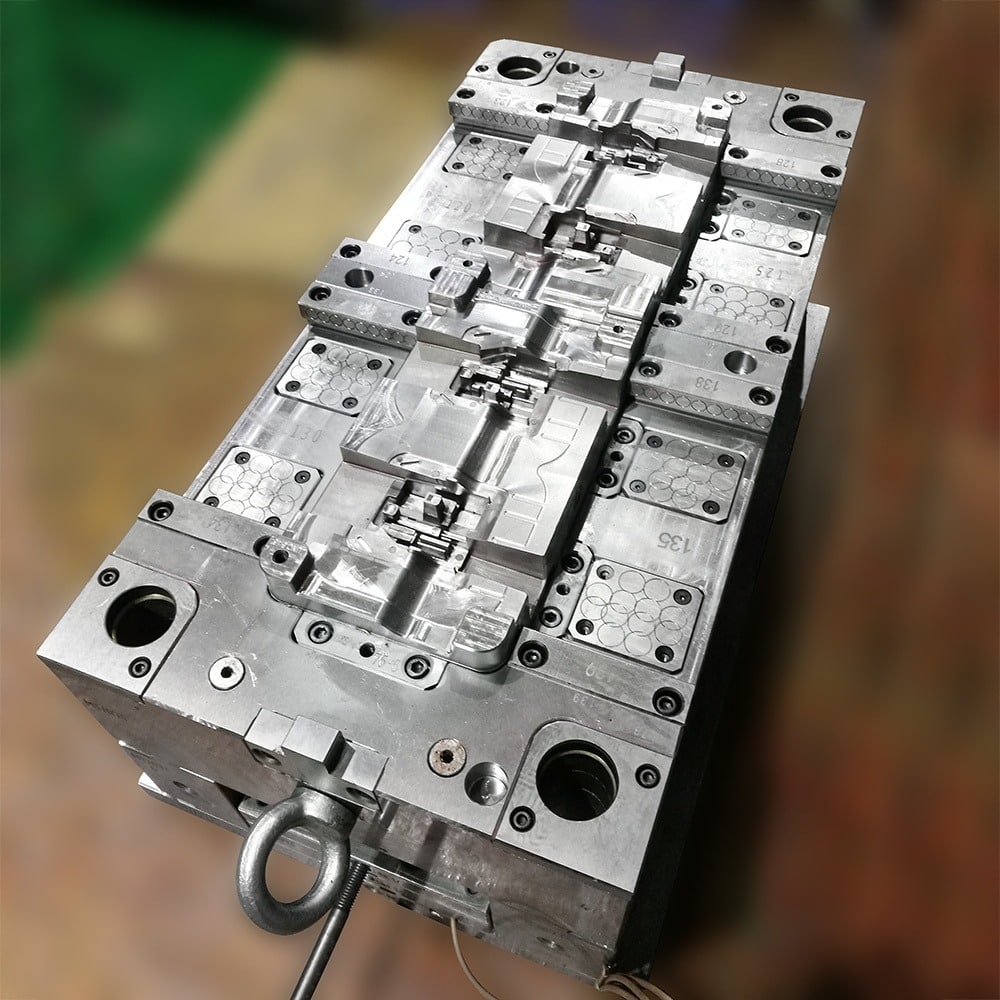

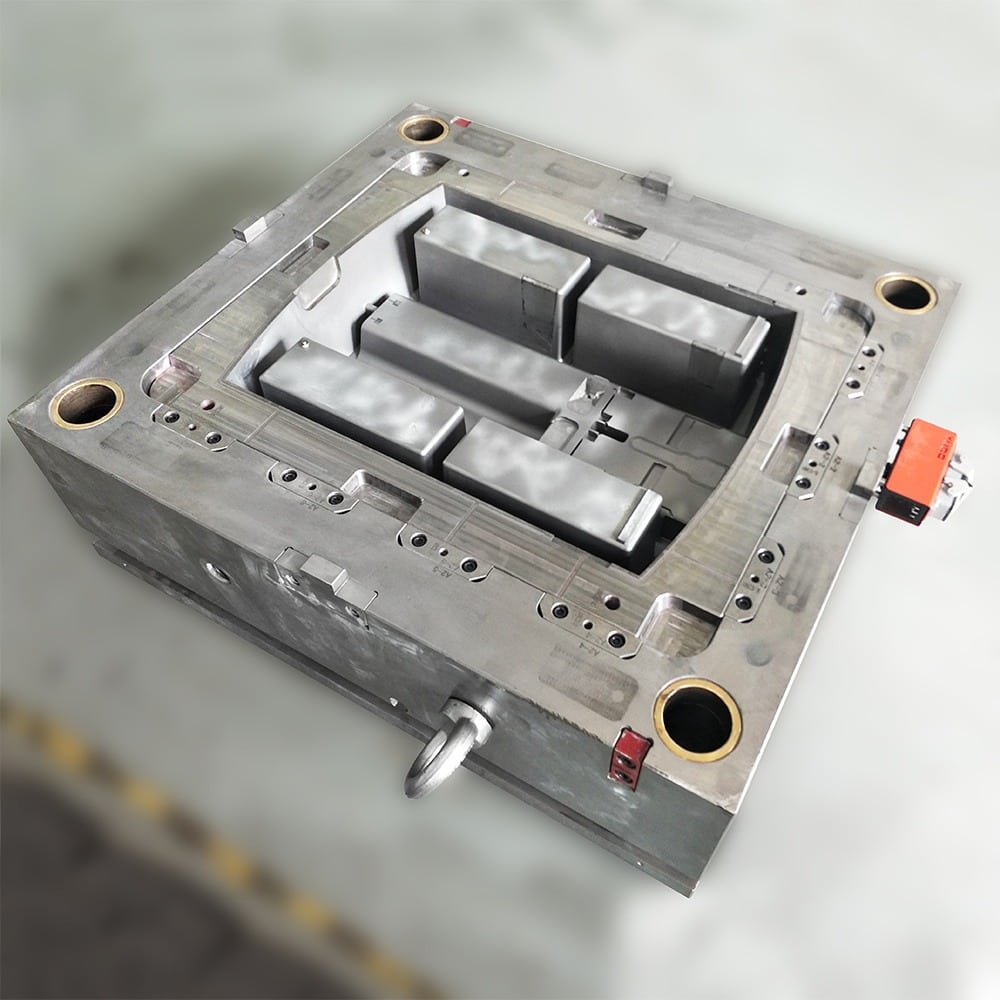

The standardization of plastic mold design should first establish a database of plastic mold design standards, including standard parts for single parts, standard accessories for assembly structures, 3D drawings required for molds, and data required for mold design. These are used by designers to call when needed, improve design efficiency and use rate of plastic mold standard parts, and realize standardization, serialization and standardization of plastic mold structure.

3. Fine processing shall be in place at one time.

The purpose of fine processing is to greatly reduce bench workers’ research and training, work in place at one time, reduce the problem of repeated processing, and all the parts processed in a set of molds should be processed at the same time, so as to realize the decision-making of efficient mold release. In addition, we should ensure the quality and efficiency of processing in the production process, and improve the efficiency while ensuring the quality, which is the management direction of modern plastic mold production.