How to analyze the machining surface of injection mold ?

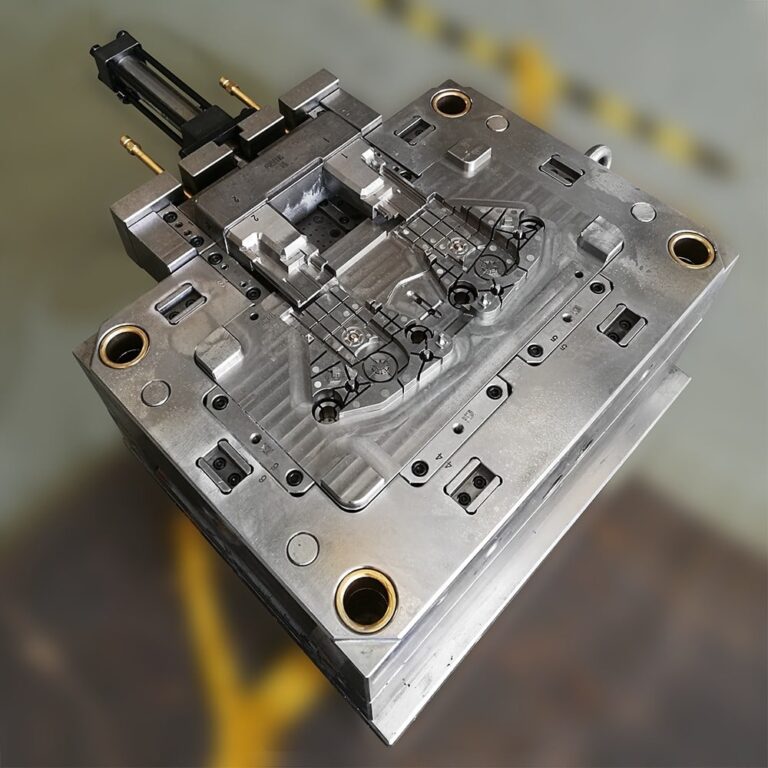

The mold is composed of many parts, and its surface shapes are flat, cylindrical surface, round money surface, curved surface, thread surface, etc.. The role of each surface in the mold is different, so it needs to be carefully analyzed to determine the processing method of each surface. From the perspective of mold manufacturing process*, according to the role of parts and surfaces in the mold and the different stages of manufacturing, they can be divided into shape surface, forming surface and structure surface, and each surface is processed to get qualified mold parts, so as to lay the foundation for the final correct assembly.

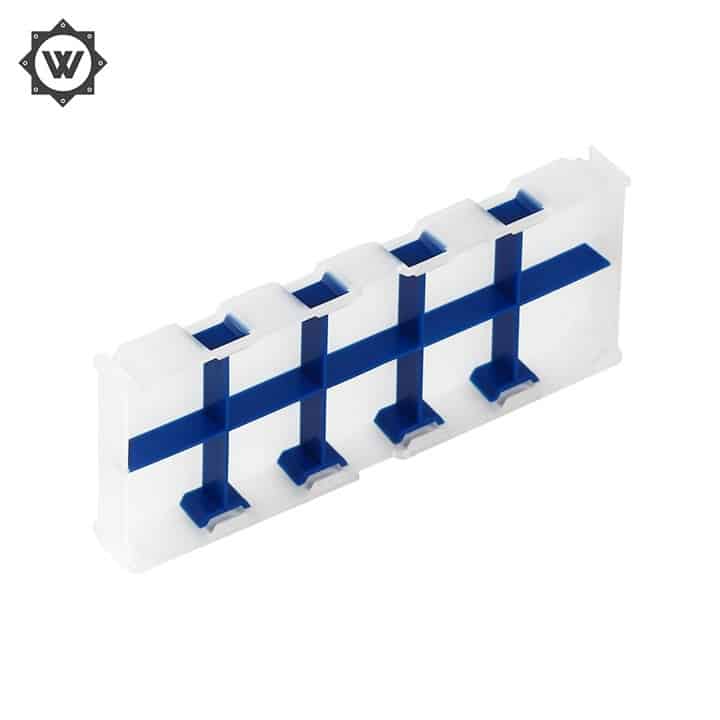

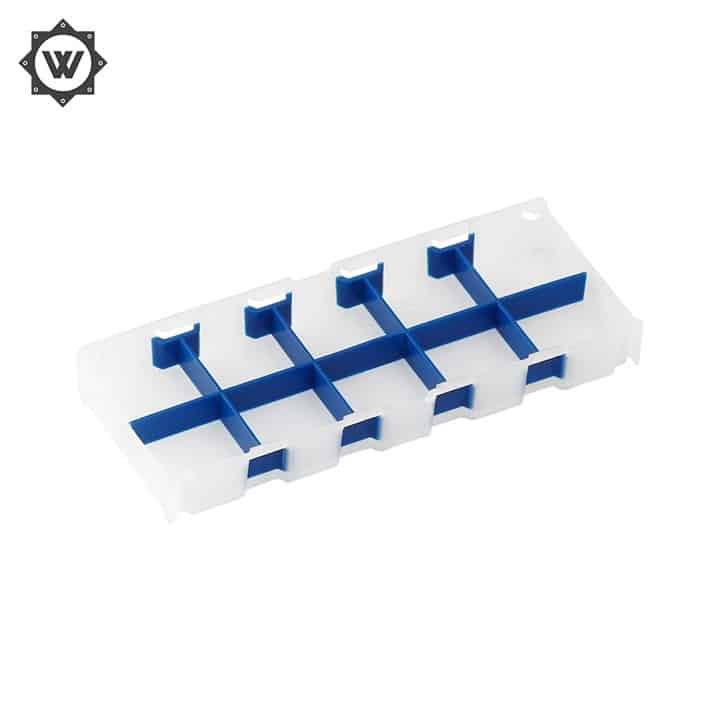

① Shape surface Shape surface is the surface that constitutes the basic shape characteristics of the mold in general, the shape surface is the outer edge surface of the part, these outer edge surfaces are mostly rectangular bodies composed of flat surfaces or rotating bodies composed of columns and cones. These form surfaces are the reference surface for processing other surfaces, or the reference surface for assembly, or may be the forming surface of a simple mold, or the parting surface of a mold, etc. The shape of these surfaces is relatively simple, easy to process more with ordinary cutting machine tools.

② molding surface molding surface is the surface in the mold directly determine the shape and size of the product parts, accuracy and coordination with these surfaces and related surfaces. Such as injection molding in the concave, convex mold work surface and work surface coordination with the template and other hole surface. Generally, the shape of the molding surface is more complex, high dimensional accuracy and small surface roughness values, and more heat treatment requirements, the consistency and coordination of the molding surface of the relevant parts have more stringent requirements. The processing of such surfaces generally can not be processed by ordinary machine tools, but need to use special processing. Molding surface processing is one of the key points and difficulties in the injection molding process.

③ Structure surface Structure surface refers to the positioning, guiding, distance setting in the mold. Limit, connection, drive and other role of the surface. It plays a very important role in the mold to ensure the relevant size and position accuracy between each part, for the reliability of the connection and mutual movement. The shape of the structural surface is various, and the material and heat treatment requirements of different parts are also different. Generally, the role of the structural surface of each part should be treated differently according to the relationship with other related parts.