How to choose the TPE for two-color injection molding?

In the field of plastic processing, some plastic products, for functional and aesthetic considerations, the whole product needs two or more plastic materials to go with. The matching of plastic materials can be done by processing different plastic parts separately and then assembling them together, or by using injection molding to complete the combination of different material parts, which we call dual-material and multi-material injection molding. Among them, dual-material injection molding is the main method. Dual-material injection molding can be quickly processed by two-color injection molding machine, but also the use of overmolding mold to process, the industry is also known as set of beer, embedded injection, secondary injection or overmolding. So how should we choose the TPE material for two-color injection molding?

The selection of two-color injection molding TPE has the following methods.

1, two-color injection molding in the mold runner is generally long, so the material should have good thermal stability and processing fluidity to avoid degradation caused by long residence time in the runner during the molding process, resulting in bad appearance such as silver wire and yellow lines.

2, chemical resistance (solvent corrosion), permanent deformability, hydrolysis resistance, weather resistance (UV, aging, low temperature), antistatic, flame retardant, oil spray printing, VOC odor test, antibacterial and anti-mold, related food grade medical grade test, etc. The potential requirements for products may vary from industry to industry. Need to do specific communication to confirm.

3、Hardness is determined by the product application requirements. Usually the hardness standard needs to be provided by the customer with the required physical parameters of the TPE cover material, or directly provide an OK product sample; as a standard to confirm the hardness.

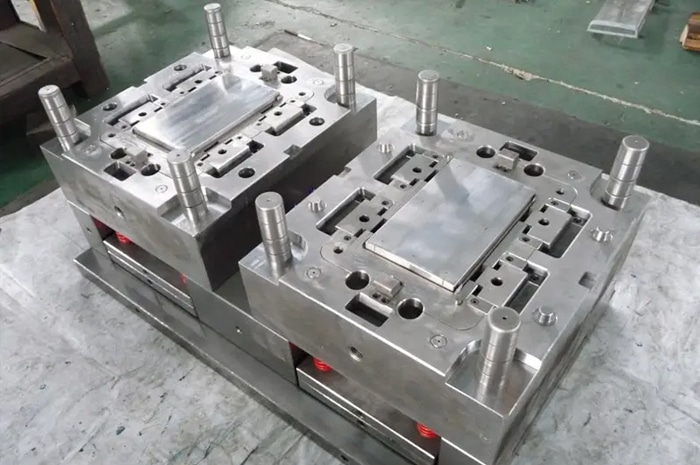

4, the two materials must have good compatibility, if necessary, can also be added to the substrate groove, convex groove, etc. to increase the bonding strength.