How to control the service life of dies

Mold is closely related to our life. It can be said that modern people are increasingly inseparable from the use of mold products. For example, mobile phones, televisions, water cups for drinking… and the quality is so good that people doubt it.

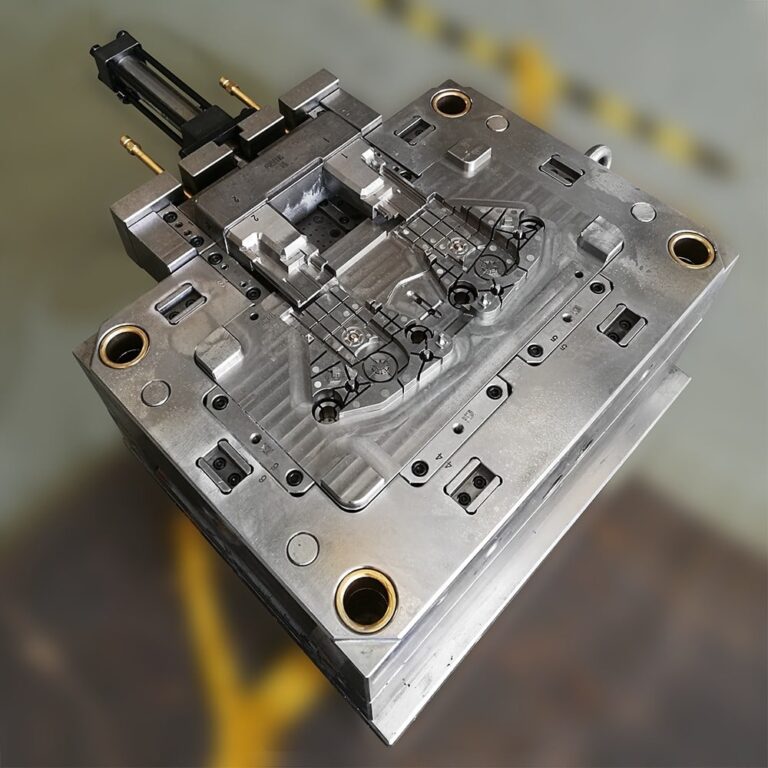

The mold time is that every time our mold is closed for production, it is called 1 mold time. How many times has a mold been produced, and how many times is the design life of the mold? Our company stipulates that the design life of plastic mold is 500000 mold times. If it is the first mock examination with eight holes, it will produce 4 million EA products. Of course, the mould will not be produced after 500000 mould times, and will be scrapped. It depends on the actual production status of the mold. If the mold is in good condition, production can continue.

If the situation is not very optimistic, and the mold core and mold base have been seriously deformed, then the significance of repair is not great. When the die deformation intensifies, once the processing benchmark is lost, the only way to live is to “live a dead horse as a living horse doctor”, which cannot be repaired, but to reopen a new die. The regulation of 500000 module times is only a benchmark reference value. Of course, each enterprise has its own corresponding regulations, which can only be said to vary from person to person.

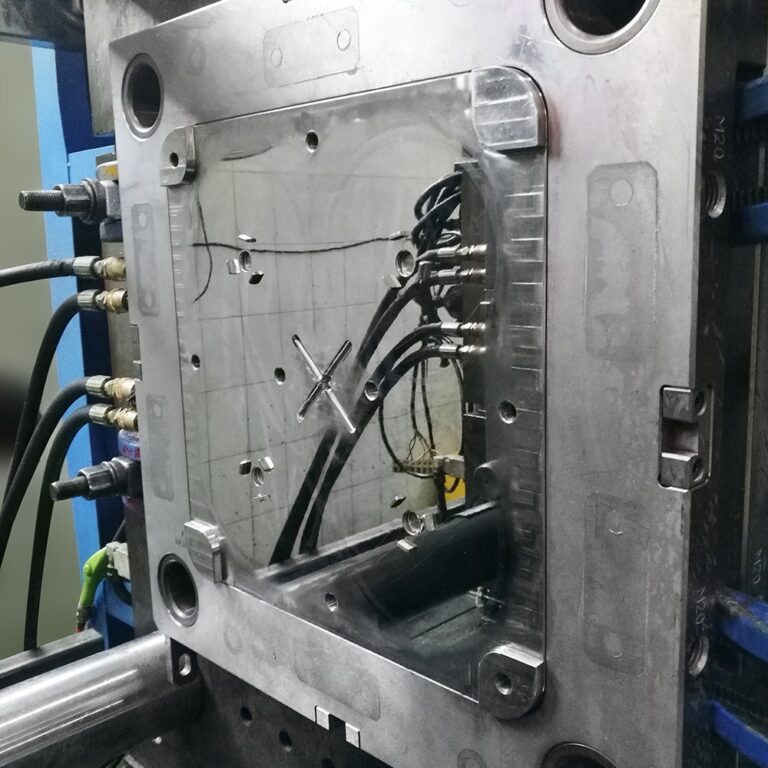

It starts from the time when a mold is handed over to the mold product manufacturer after the small batch trial mold production is stable from the mold manufacturer. The mold product manufacturer must control the repair and maintenance, production, quality inspection, life and other records of this mold.

1.Use the Mold Repair Request and Mold Repair Record Form to control the mold

In case of any abnormality of the product or mold, the on-site operator shall fill in the Mold Repair Request and notify the mold repair personnel. The repair request sheet contains the name of the mold to be repaired, the date and time of the repair, the brief description of the reason for the repair, the job number of the repair personnel, and the mold production life (the mold is damaged when the mold is produced to the number of times).

The rest is the completion time filled in by the repair personnel, the job number of the repair personnel and the repair content. For the repair content, the repair personnel must summarize the repair process completely, and it is required to fill in truthfully, with concise sentences and neat and clear handwriting. Such a Mold Repair Request is like a case book issued by the doctor to the patient, while the Mold Repair Record Form is the patient’s lifetime case file data (from production to scrapping).

The repair personnel can carry out regular mold maintenance according to the mold production life provided on site, and the data is a reference basis. For another example, after a certain number of molds have been produced, the products must be submitted for inspection according to the company’s operating regulations.

The mold repair personnel shall successively fill the Mold Repair Request for the same mold in the Mold Repair Record Form within one year for summary, so that the mold repair personnel can timely and quickly find the mold repair records and some information related to mold design changes within one year. The Mold Repair Record Form can be bound at the end of each year, or saved and managed in the form of computer files.

2.Use the Mold Life Record Form to control the mold

Our company records the mold life according to the production quantity records of products. For example, when a work order is completed, the production quantity on the work order is divided by the number of mold holes, and then the computer table records are accumulated. (If the plug mold cavity on the mold is caused by temporary or permanent irreparable reasons, it is actually calculated by dividing the production quantity on the work order by the actual production mold cavity number.).

After the specified mold times are accumulated, the product of this batch shall be sampled and submitted for inspection, and the quality inspector shall measure the full size of a whole hole of the product. If the measured size is qualified, it is approved that it can be produced. If there is a problem with the size of the product other than the inspection point, the performance test shall be carried out, and the product can only be used after passing the test. Inspection points must be ensured. If the inspection points have poor dimensions, they need to be repaired.

Of course, some mold manufacturers now add mold counters to the original mold when developing the mold, but some counters are sometimes inevitably damaged by external forces. Sometimes, due to the poor counting quality of the counter, it is not necessary to count and accumulate any more. Try to use the mold counter to select the ones with excellent quality.

3.Evaluate the mold condition in advance

After the abnormal damage of the mold occurs, how to prevent its recurrence needs to review the corresponding countermeasures. When the technician damaged the mold artificially, he hid or told the truth afterwards (unwilling to tell the truth) for fear of being blamed by the supervisor. In this way, it is impossible to avoid the recurrence of similar events in the future.

Like Holmes, the mold repair personnel have to infer the original process of things from the perspective of damage and mechanical operation principle. In reality, if we don’t pay attention to it, the same thing will happen again and again. If this kind of abnormality is not ruled out, it will be like a “bomb” that can explode at any time. And the life of the mold can’t stand such a toss!

Under the premise of referring to the service life of the mold, mold repair needs to carry out an early assessment of the mold condition, especially if the mold is frequently damaged abnormally, it is not possible to apply for a new mold after the mold cannot be produced normally.

Our company produces the same product, because the demand for the product is large, so a pair of molds does not reach the mold life, and we usually apply for new molds in advance. Of course, sometimes because of the rush of orders, there will be two sets of molds produced at the same time… One pair of molds is in good condition and normally produced, and the other pair is not very good, which plays a role in temporary cooperation with production. Some newly opened moulds have the same structure as the old ones, but some have different structures.

Which molds are better in structural application and more stable in production? In the process of our usual mold maintenance, we should learn to be good at summarizing and judging. In the early stage of new mold development, put forward reasonable suggestions for improving the mold structure or selecting better mold materials, and discuss the feasibility with the mold manufacturer.

For example, the products with large quantity and single color can be considered to adopt hot runner structure. There is no return material and the gate does not need manual treatment, which can save the waste of raw materials and manpower. Whether the products of the original side gate can be changed into submerged or point type pouring, so that the operator can eliminate the operation of burring the gate and save manpower, thus realizing automatic production.

In some places where the male mold or female mold is often broken and damaged, processing inserts or optimizing mold materials can be used to deal with it, which is convenient for maintenance personnel to repair, reduce the frequency of repair and on-site technicians to dismantle the mold back and forth, as well as the loss caused by downtime.

4.New mold application

After evaluating the mold condition in advance, apply for re opening of new mold for the same product according to the company’s process. First, the mold repair department shall issue a paper Mold Production Equipment Application Form, which shall be signed and approved by the supervisors at all levels. Next, the “Mold Production Equipment Application Form” shall be issued in the computer ERP system, and then the supervisors at all levels shall sign and confirm in the system.

Finally, the R&D unit, according to the requirements of the on-site and die repair on the Mold Production Equipment Request Form, will send the new mold manufacturing to the mold supplier for the manufacturing of the new mold, and is responsible for the confirmation of the product size and function after the new mold trial.

5.Scrapping of old mould

The old molds are discarded and sold by the mold repair department. First, the die repair department shall issue the Die Scrapping Sales Signature, which shall be approved by the directors at all levels in writing. Next, the mold repair department shall issue the Fixed Assets Disposal Application Form of the mold in the computer ERP system.

If the mold is a tax exempt asset, an Application Form for Tax Exempt Asset Disposal should also be issued, and then all levels of supervisors should sign and confirm in the system. Finally, the mold can be disassembled and scrapped after being approved by the supervisors at all levels, and then recycled by the recycling company.