How to maintain the hot runner system?

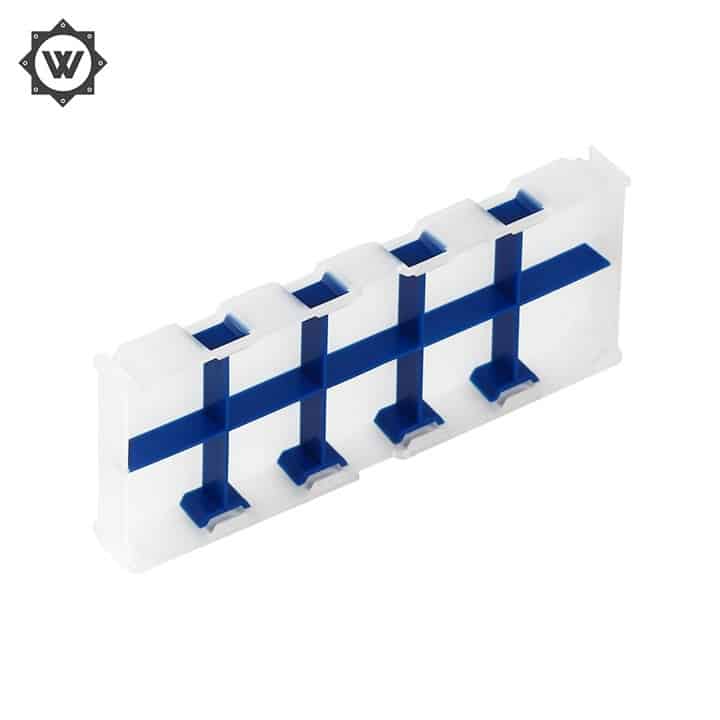

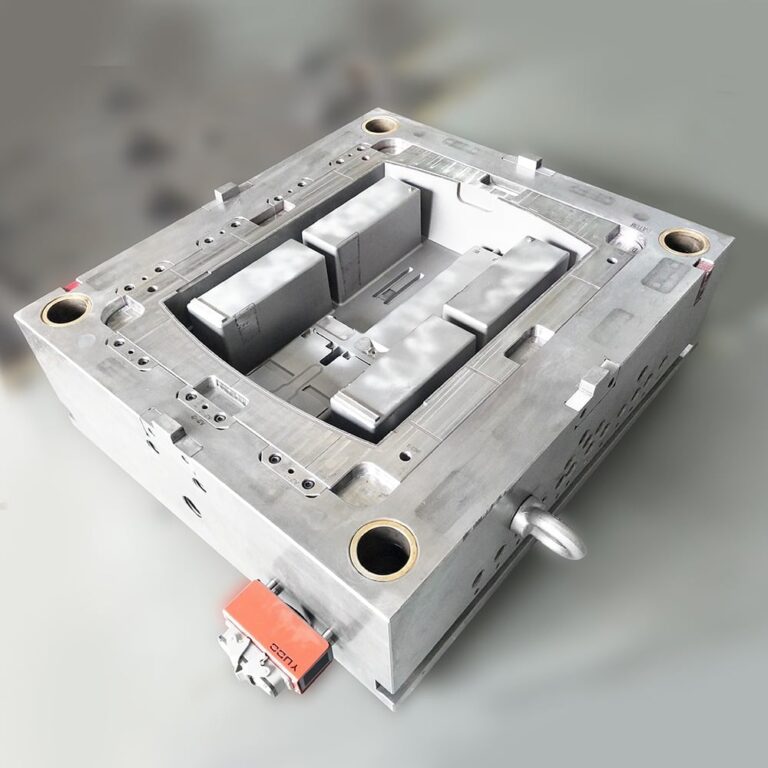

The hot runner system is a kind of widely used plastic molding gating system, which mainly uses the heating device and electronic temperature control system to prevent the molten plastic in the gating system from solidifying, so as to smoothly and orderly fill the plastic into the mold cavity. In the absence of injection pressure, the molten plastic will not flow automatically, nor will wire drawing, overflow and other phenomena occur with the demoulding of plastic products. Therefore, the hot channel mold is also known as the mold with no or few channels.

For a long time, the feeding system of plastic mold has always used cold runner to inject molten plastic into the mold cavity. With the progress of science and the continuous development of productivity, people begin to realize that there are many disadvantages in traditional injection molds, among which the generation of runner waste makes the molding cycle longer, the production efficiency is low, and directly leads to the increase of costs. With the emergence of 3D software, the structure of plastic products is becoming more and more complex, and the requirements are also getting higher and higher. Therefore, the traditional mold molding process has been difficult to meet the needs of modern products, and people have to consider using other technologies. At the end of the 1950s, American Incoe Company invented the hot runner injection molding mold technology, which set off a revolution in the mold industry. Especially in recent years, with the development of microelectronics technology and the invention of electronic temperature control box, the hot runner system has developed to a very mature stage.

The hot runner system is equipped with an electric heating rod and an electric heating ring near the runner during operation. Therefore, the entire runner from the nozzle inlet to the gate of the injection molding machine is high temperature, and the plastic in the runner has always maintained the melt condition. Even after the shutdown, it is unnecessary to open the runner to take down the melt. If the temperature is increased to the required temperature during the next startup, it is OK. How to maintain the hot runner during operation and after shutdown?

First of all, it is necessary to determine the application and maintenance personnel. If problems are found, immediately communicate with the maintenance personnel or the manufacturer to describe the situation and problems, so as to ensure that the maintenance personnel can immediately treat the symptoms.

Second: In case of self maintenance, the following aspects should be paid attention to:

1. If the plastic is highly sensitive to temperature or corrosive, the residual melt should be removed with PP after each shutdown;

2. At ordinary times, it is necessary to remove all the water vapor, fog water, oil stains and other dirt adhered to the hot runner to prevent corrosion of hot runner system components;

3. If the mold is stored for a long time, the heater may be corroded by moisture, and it needs to be dehumidified before application;

4. If the hot runner needle valve system is used, maintenance should be done every two months to prevent the activity from being blocked due to carbonization or gas dust scaling.