In the injection molding process, it is often difficult to solve the shrinkage of a certain part of the product. In this case, only by using the back pressure and adjusting the back pressure parameters properly can we solve the problem.

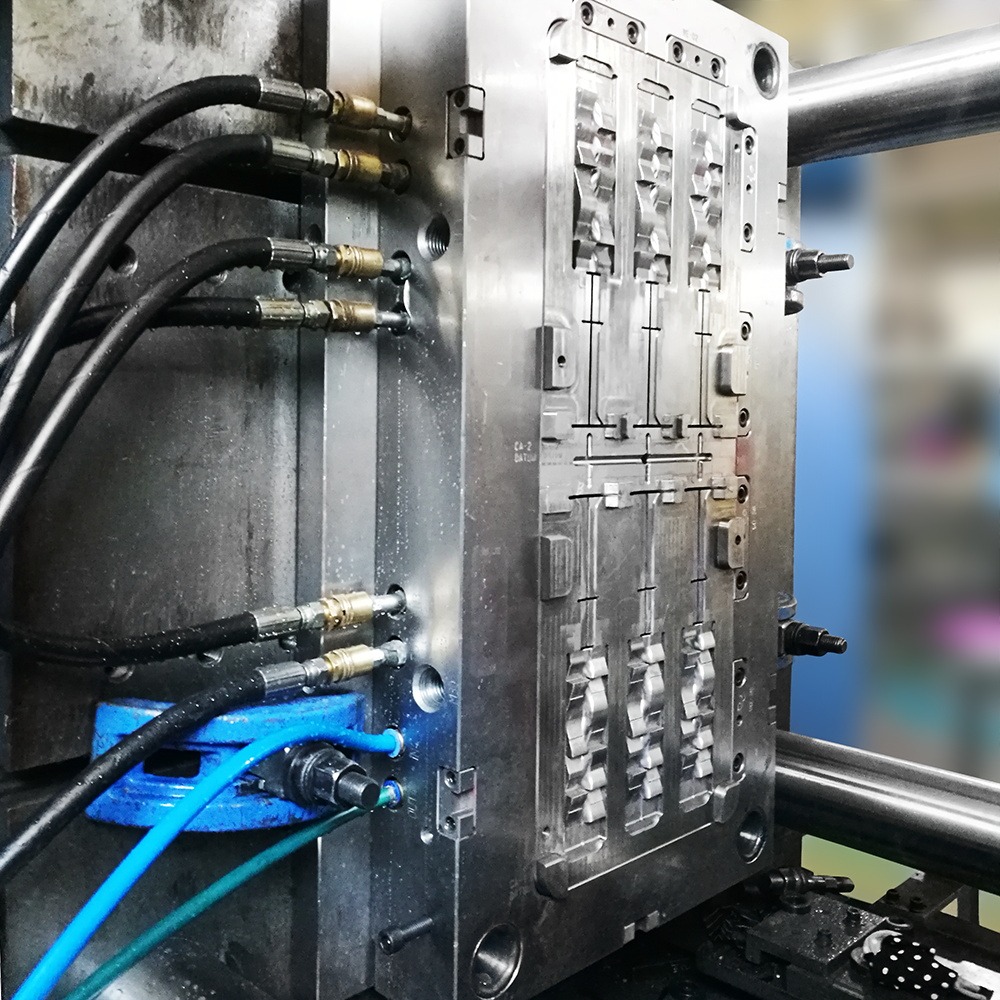

The reason for using back pressure is that when the screw rotates, the hot plasticized plastic is pushed forward under the action of the screw and reaches the front of the screw through the stop valve. As the molten material moves forward, the molten material produces a reaction force, which acts on the screw and the stop valve, making the screw move backward so that more molten material moves forward. At this time, if the back pressure is adjusted, the cylinder has a certain pressure from the back to the front on the screw, It provides resistance for the screw to retreat. The greater the back pressure is, the longer the screw reset time is. The pressure generated by the molten material at the front of the screw must be greater than the back pressure before the screw can retreat. It must be pointed out that not all injection molding production must use back pressure, but if back pressure is used, the plastic can be fully melted and mixed evenly.

The use of back pressure in the injection molding process has more advantages: First, it is conducive to the emission of volatile gases in the melt. 2、 Make the additive and molten material mix more evenly. 3、 Make the plastic plasticization more uniform, etc.