Injection system of injection machine

The injection system is a part of the injection machine that works in direct contact with the molding material and melt. Its main function is to make the solid molding material plasticize into melt evenly and inject the melt into the mold cavity with sufficient pressure and speed. The injection system includes the charging device, barrel, plunger and diversion cone (plunger injection machine), screw (screw injection machine) and nozzle.

(1) Feeding device

Also known as a hopper, it is usually an inverted cone or square cone metal container installed in the higher part of the injection machine and connected to the barrel.

(2) Barrel

That is, the plasticizing chamber of the molding material, mainly used to heat the molten material.

(3) Plunger and diversion cone

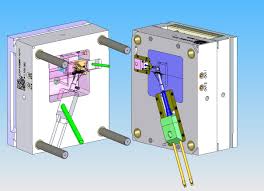

Plunger and diversion cone are the injection and plasticizing parts installed in the barrel of the plunger injection machine. Plunger in the barrel of the machine to do reciprocal linear motion, pushing and compressing the plastic melt through the nozzle into the mold. The diverter cone is a diverter part installed in the front center of the barrel, as shown in Figure 4-6.

Its working principle is: the melt is split into thin layers when passing through the diversion cone, and produce convergent flow, which shortens the heat transfer distance of the barrel to the material and improves the heat transfer effect; at the same time, the material is accelerated in the gap between the diversion cone and the barrel, and the shearing effect is enhanced, which generates a certain amount of frictional heat. The two aspects work together to improve the plasticizing and equalizing effect of the material.

The setting of the diverter cone can shorten the plasticizing time of the material, improve the flowability of the plastic melt and the molding quality of the plastic parts, and increase the production efficiency.

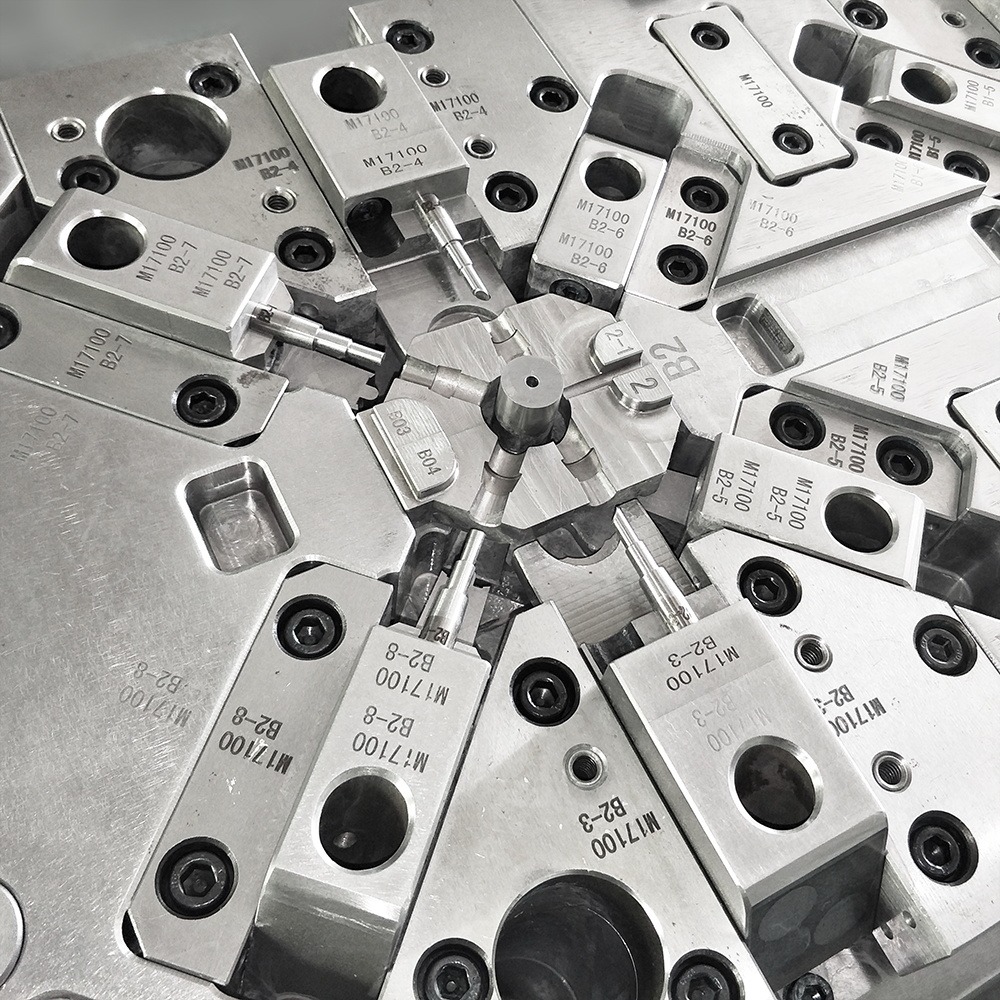

(4) Screw

The screw is an important part of the screw injection machine, through the rotation and axial movement of the screw in the barrel to realize the plasticization and injection of the molding material.

(5) Nozzle

The nozzle is installed in the front of the barrel, and the internal nozzle hole is the channel connecting the barrel and the mold, which guides the plastic melt from the barrel into the mold.

Translated with www.DeepL.com/Translator (free version)