Main advantages of TPE applied to adhesive coating

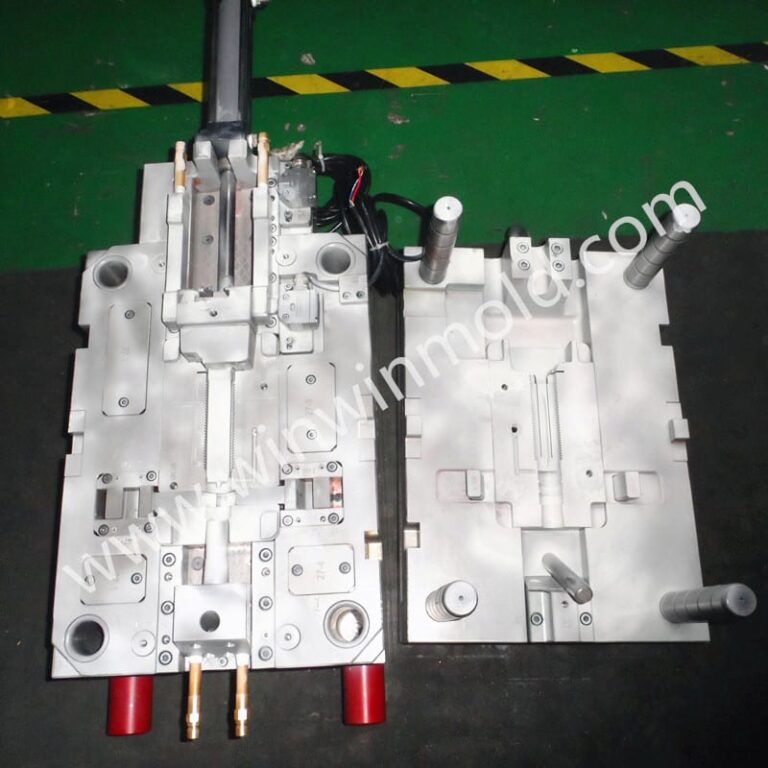

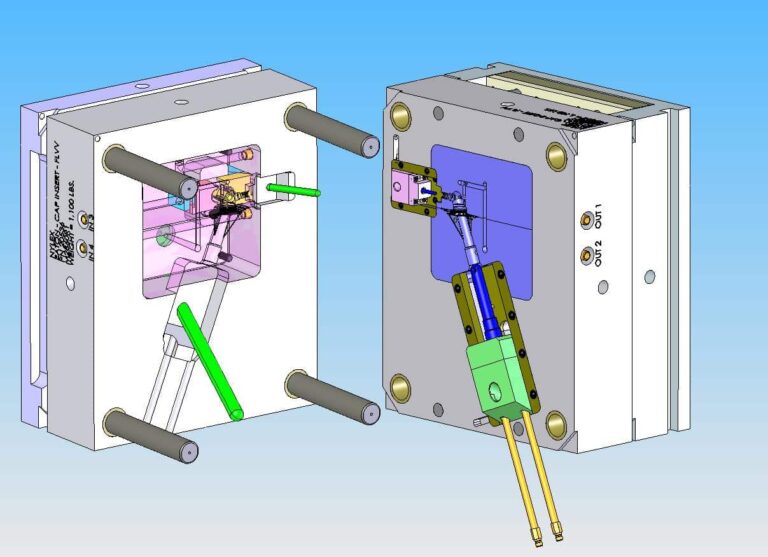

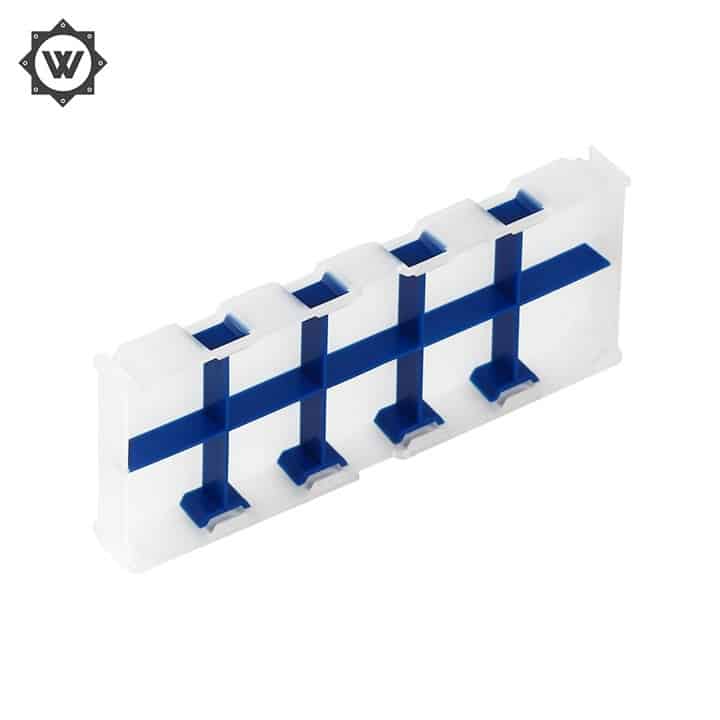

TPE adhesive coating refers to coating TPE soft adhesive material onto other materials. Generally, the processing methods used are two-color injection molding machine for one-time molding or general injection molding machine for secondary injection molding using rubber coated mold. TPE plastic coated products are generally handles and handlebars. Because of the special comfortable touch of TPE soft adhesive material, the introduction of TPE material has improved the grip and touch feel of products.

TPE in the elastomer industry usually refers to composite functional materials obtained through SEBS modification. TPE elastomer soft adhesive has the induction function, which is commonly used in secondary injection molding, plastic coating injection bonding molding and two-color injection molding.

Main advantages of TPE applied to adhesive coating

TPE elastomer soft adhesive shall be used for secondary injection molding and adhesive injection. Because TPE material has good skid resistance and good elastic touch, it can improve the touch feel of products and enhance the grip.

TPE elastomer soft adhesive can be adjusted to appropriate hardness (hardness range Shore 25-90A) and appropriate physical properties (such as abrasion resistance, scratch resistance, cohesiveness, melt index, etc.) according to the physical property requirements of the product. Various possible material application schemes are provided for different products.

TPE is processed by adhesive coating, commonly used products such as handles, grips, electronic materials, etc. The materials give the product a comfortable touch, improve the grip, enhance the beauty of the product and the added value of the product.

Most of the products are exported to the United States, Japan, the European Union and other developed countries and regions. As TPE elastomer soft adhesive is a green and environment-friendly raw material, the material does not contain phthalates, halogens and 38 SVHC substances of high concern specified by REACH. It conforms to ROHS, REACH, NP, EN71, PAHS environmental protection testing standards, and can fully meet the environmental protection requirements of developed countries and regions such as the United States, Japan, and the European Union.