Composition of hot runner system

Although there are many hot runner manufacturers and various hot runner product series in the world, a typical hot runner system consists of the following parts:

- Hot runner plate

- NOZZLE

- Temperature controller

- Auxiliary parts

Advantages of Hot Runner Mold

Hot runner die is widely used in the developed countries and regions in the world.

This is mainly because the hot runner mold has the following significant features:

- Shorten the molding cycle of the parts. Because there is no restriction on the cooling time of the runner system, the parts can be ejected in time after molding and curing. The forming cycle of many thin-walled parts produced by hot runner molds can be less than 5 seconds. Because there is no cold runner in pure hot runner molds, there is no production cost. This is especially significant for the application projects with expensive plastic prices. In fact, the major manufacturers of hot runner in the world have been developing rapidly in the era of expensive oil and plastic raw materials in the world. Because hot runner technology is an effective way to reduce material cost.

- Reduce waste products and improve product quality During hot runner molding, the temperature of plastic melt is accurately controlled in the runner system. The plastic can flow into each mold cavity in a more uniform state, and the result is a part with the same quality. The parts formed by hot runner have good gate quality, low residual stress and small deformation after demoulding. Therefore, many high-quality products on the market are produced by hot runner molds. For example, many plastic parts in the familiar MOTOROLA mobile phones, HP printers and DELL laptops are made with hot runner molds

- The elimination of subsequent processes is conducive to production automation. The finished product is formed by the hot runner mold, and there is no need to trim the gate and recycle and process the cold runner. It is conducive to production automation. Many foreign product manufacturers combine hot runner with automation to greatly improve production efficiency.

- Expanding the application of injection molding process Many advanced plastic molding processes are developed on the basis of hot runner technology. For example, PET pre molding, multi-color co injection in the mold, multi material co injection process, STACK MOLD, etc.

Disadvantages of hot runner mould

Although compared with cold runner mold, hot runner mold has many significant advantages, but mold users also need to understand the disadvantages of hot runner mold. To sum up, there are the following points:

- Mold cost rise

The price of hot runner components is relatively expensive, and the cost of hot runner molds may increase significantly. If the output of parts is small, the proportion of mold and tool costs is high, and the cost is not calculated economically. For many mold users in developing countries, the high price of hot runner system is one of the main problems affecting the wide use of hot runner mold.

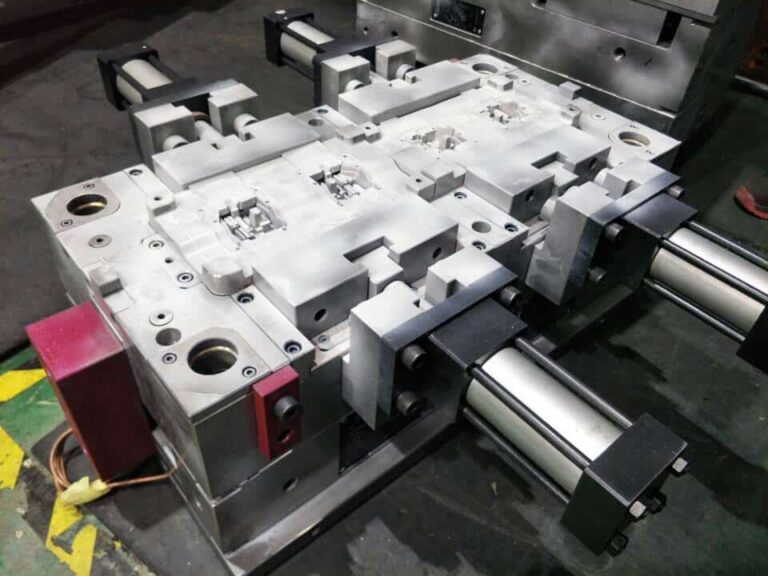

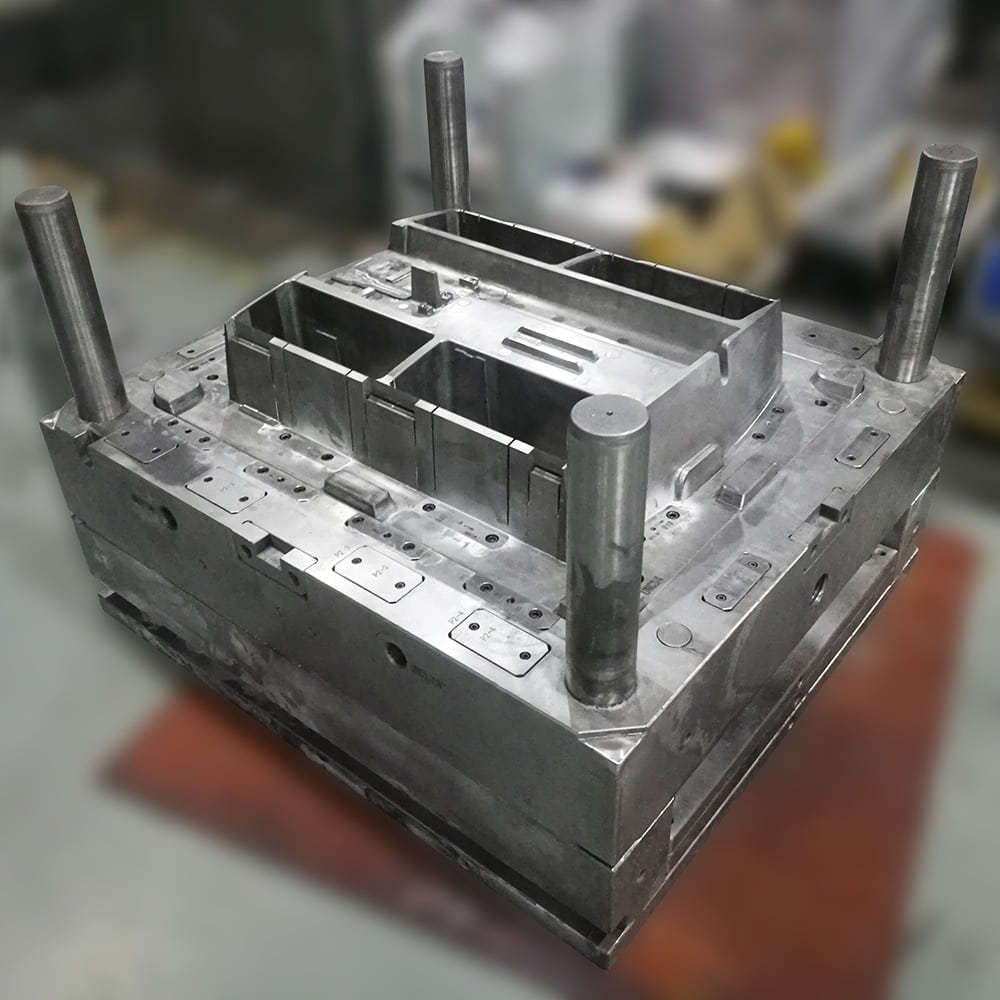

- High requirements for hot runner mold manufacturing process and equipment

The hot runner mold needs precision machining as a guarantee. The integration and coordination between the hot runner system and the mold are very strict, otherwise there will be many serious problems in the production process of the mold. For example, the poor plastic sealing results in the plastic overflow, damages the hot runner components and interrupts the production, and the poor relative position between the nozzle insert and the gate results in a serious decline in product quality

- Complex operation and maintenance

Compared with cold runner mold, hot runner mold operation and maintenance is complex. In case of improper use and operation, it is easy to damage the hot runner parts, making production impossible and causing huge economic losses. For new users of hot runner molds, it takes a long time to accumulate experience