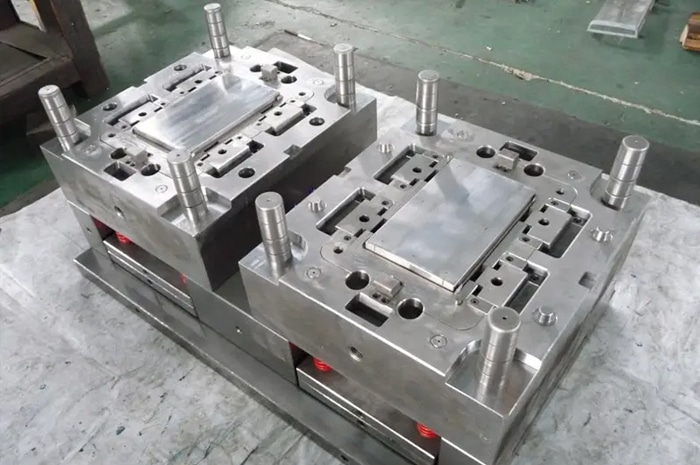

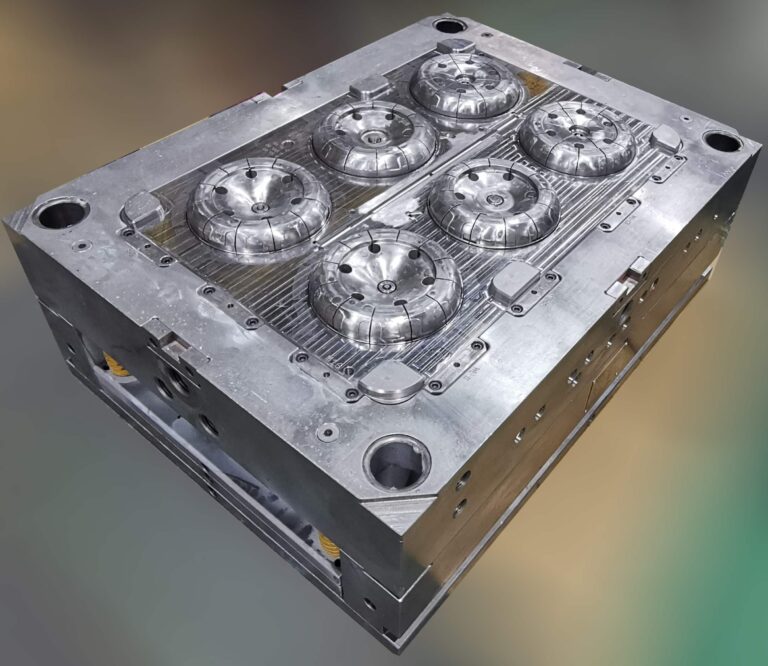

For the production of plastic mold, the customer’s engineering personnel first provide the product drawings to the mold manufacturer. The manufacturer collects, analyzes and digests the product data through the task requirements of molding plastic production, which is customized for customers.

The plastic mold customization steps mainly include:

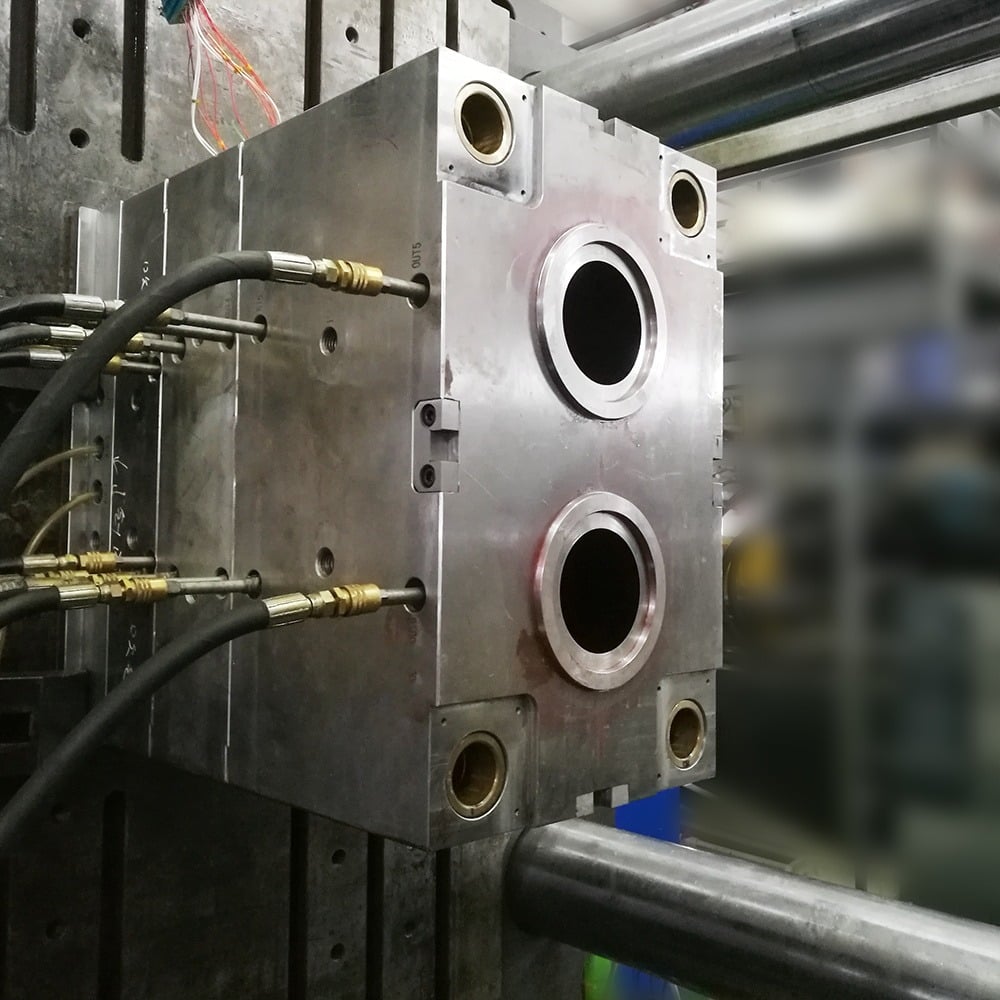

Foreign trade inquiry – issuing test article or 3d diagram – calculating price – determining mould steel – determining batch raw materials – defining appearance processing technology – customers determining good raw materials and processing technology for goods – signing a contract – paying 50% of the deposit for mould – distributing prototype making – customers determining samples – prototype samples ok – selecting and purchasing mould steel – gong machine – milling machine – CNC wire cutting – CNC flame plus production and processing – mold installation – mold testing – sample production. The above is the plastic mold opening customization steps.

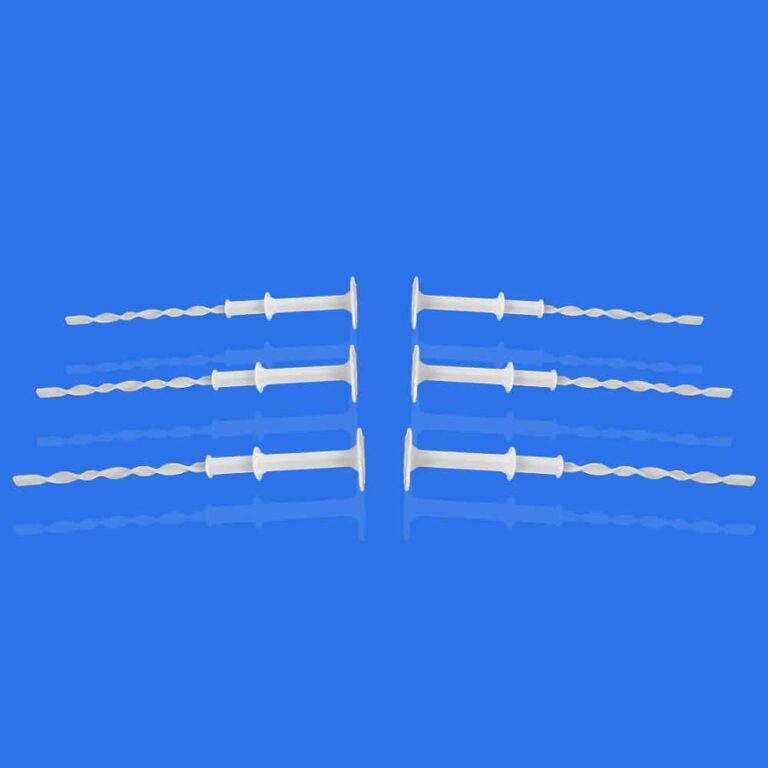

Customized injection mold products are generally innovative and good-looking, which is a unique product designed by customers according to their own needs. Then send the product 3D drawing to the injection mold factory for processing, and countersign a confidentiality contract in the early stage. Ensure that the product appearance structure will not leak.