Must-know knowledge of injection molding mold design

What are the major systems of moulds?

Pouring→Ejecting→Cooling→Forming→Exhausting

What issues should be paid attention to in the process of doing mold design?

1、The wall thickness should be as even and common as possible, and the slope of demoulding should meet large.

2、The transition part should be gradually, round and smooth transition.

3、Gates. The runner should be as wide as possible, thick and short, and the location of the gate should be set according to the shortening condensation process, and the cold material well should be added if necessary.

4, mold appearance should be bright, low roughness (preferably low 0.8)

5、Ventilation holes and slots must be satisfied to discharge air and gas in the melt in time

6、In addition to PET, the wall thickness should not be too thin, generally not less than 1mm.

What are the common defects in the obstruction of plastic parts?

Lack of glue → cloak → air bubbles → shrinkage → fusion marks → black spots → stripes → warping → delamination → peeling

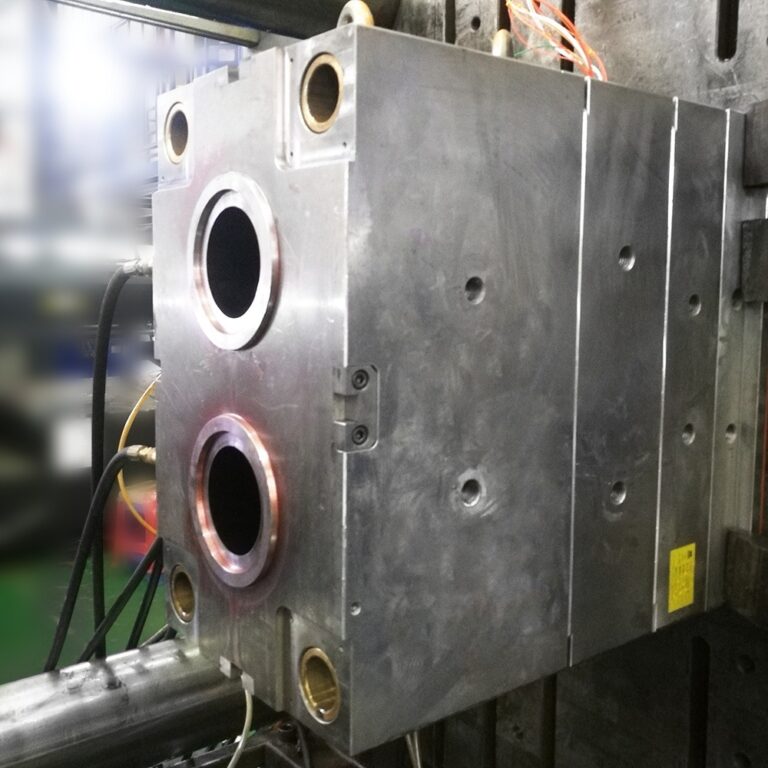

What is the structure of the mold frame?

Panel → A plate → B plate → square iron → guide pillar → ejector plate → ejector pin fixing plate → base plate

What are the basic forms of parting surface?

Straight → skewed → curved → straight → curved

How to hide each other in UG?

ctrL+B or ctrL+shift+B

What are the mechanical equipment for mold processing?

Computer gong→lathe→milling machine→grinding machine→drilling machine

What is 2D and what is 3D?

D English is: Dimension (line degree, dimension) of the prefix, 2D refers to the two-dimensional plane, 3D refers to three-dimensional space, in the mold part, 2D usually refers to the plane drawing that is CAD drawings, 3D usually refers to three-dimensional drawings.

What is the default accuracy of pro/e and what is the default accuracy of UG?

The default precision of pro/e is 0.0012MM, and the default precision of UG is 0.0254MM.

What are the top four companies in the world that produce mold frames?

Germany: HASCO Japan: FUTABA (double leaf) United States: DME China: LKM (Longji)

What is the default word height of CAD?

The default word height of CAD is: 2.5MM.

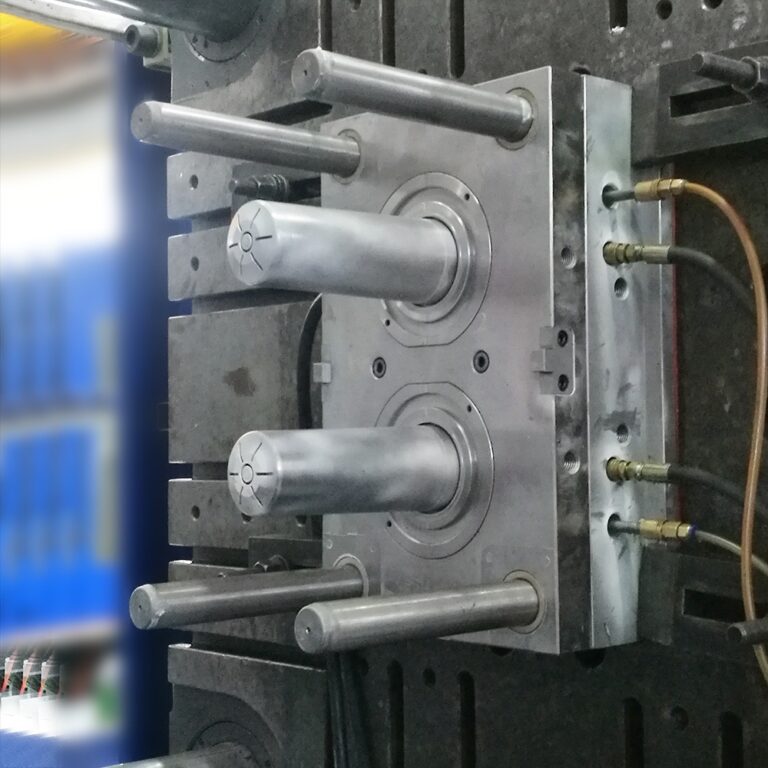

What is a touch-through and what is an insertion?

The male and female die lamination surface that is parallel to PL surface is called touch through surface, and the male and female die lamination surface that is not parallel to PL surface is called insertion surface.

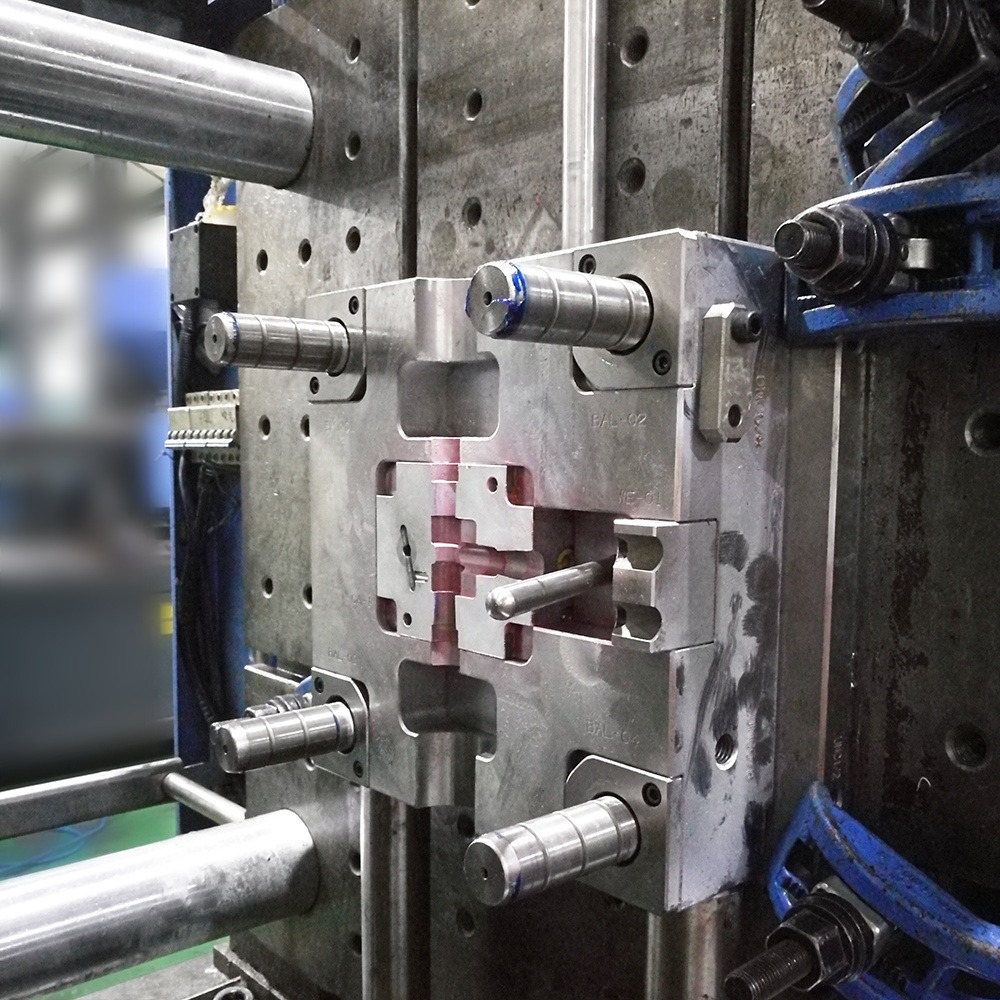

What is the pillow position?

The edge of the shell plastic parts often has a gap for installing various accessories, the pillow part is called pillow position.

What are the common defects of plastic parts?

Lack of glue → cloak → bubble → shrinkage → fusion marks → black spots → stripes → warping → delamination → peeling commonly used plastic mold steel?

45# S50c 718 738 718H

738H P20 2316 8407 H13

NAK80 NAK55 S136 S136H SKD61

What kind of outline material is used for high mirror polishing?

Commonly used high hard heat treatment steel, such as: SKD61, 8407, S136

Injection mold design experience and ideas analysis.

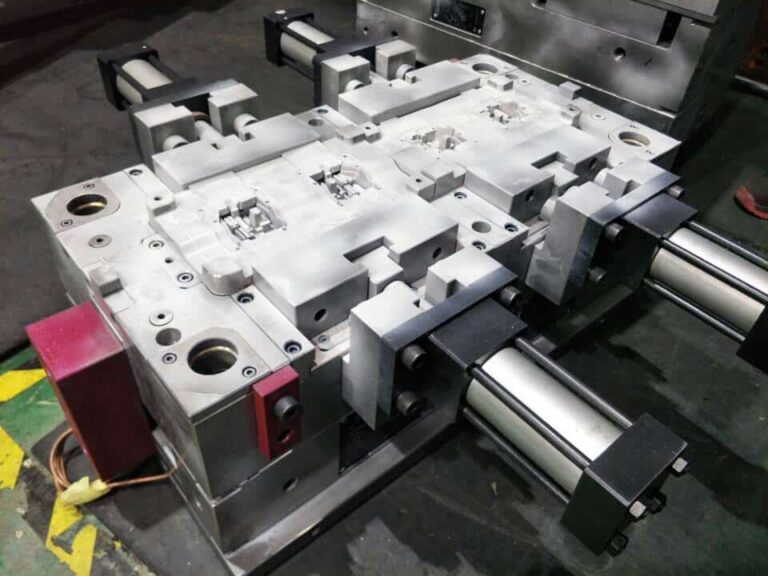

The first step: product analysis and modification, determine the mold structure, shrinkage chart:

1, product analysis.

Mold opening direction, parting line and parting surface, external dimensions, thickness, mold pulling angle, backhoe and corresponding core extraction method, glue feeding point and glue feeding method, number of mold cavities, etc.

2、Transfer engineering drawings.

Using three-dimensional software, generally establish three views: the first main view (rear mold surface projection), the second third three-dimensional schematic (external and internal surfaces). Other views are placed according to the third angle method or the first angle method, section view (X and Y, section position line through the center of important locations, inverted hook, column position, hole position, pillow position, etc.), save the file DXF format, to CAD open the standard number of processing.

3, shrinkage chart.

Mirror the previous step of the project once and enlarge a multiple of the shrinkage rate. (marked: MI, shrinkage rate)