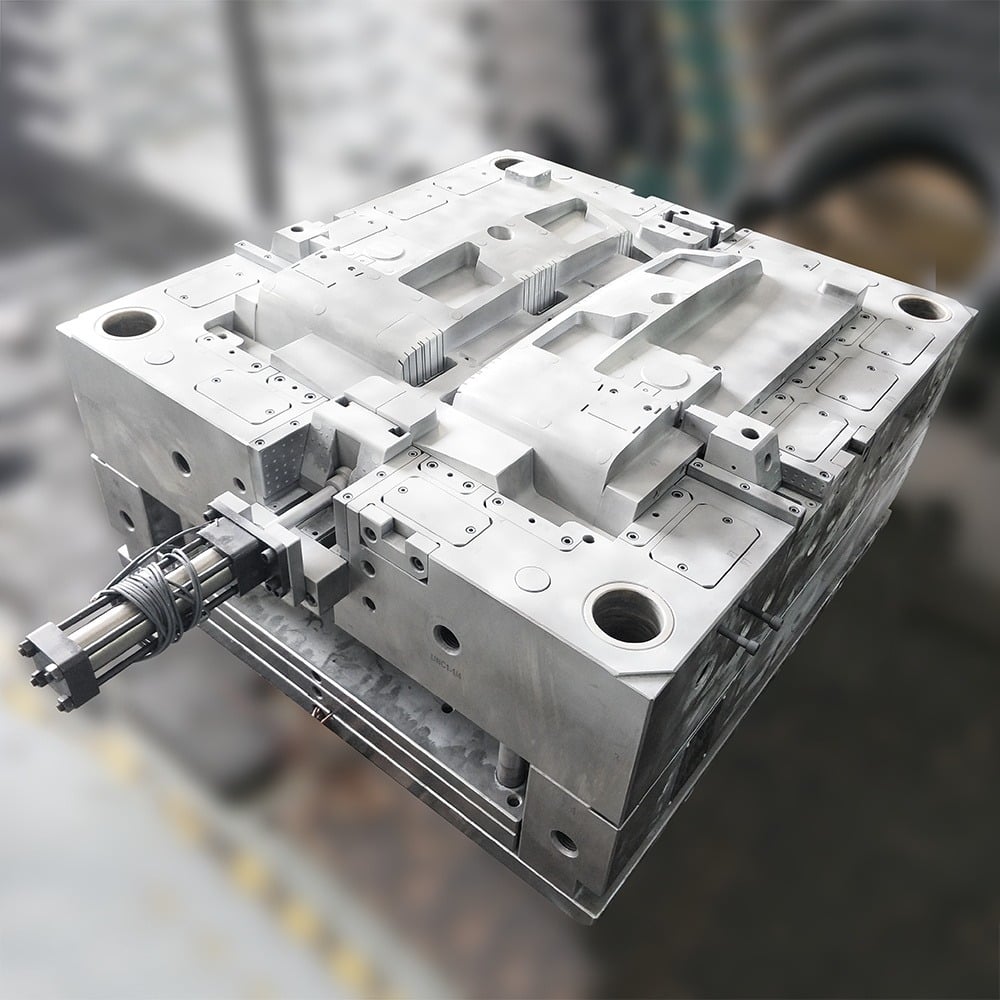

Mold assembly is like assembling a machine. Each component and each screw must be free from errors. Otherwise, the consequences will be very serious. It will lead to product defects, affecting production, and the worst is to damage the mold and lead to scrap. Therefore, assembly work must be carried out very carefully. In the process of assembly, pay special attention to the cleaning of molds such as waterways and screw holes.

Before assembly, carefully study and analyze the general assembly drawing and part drawing, understand the functions, characteristics and technical requirements of each part, and determine the assembly benchmark Through assembly, the product quality indicators, mold movement accuracy and technical requirements in the use process can be fully achieved.

1、 Assembly datum

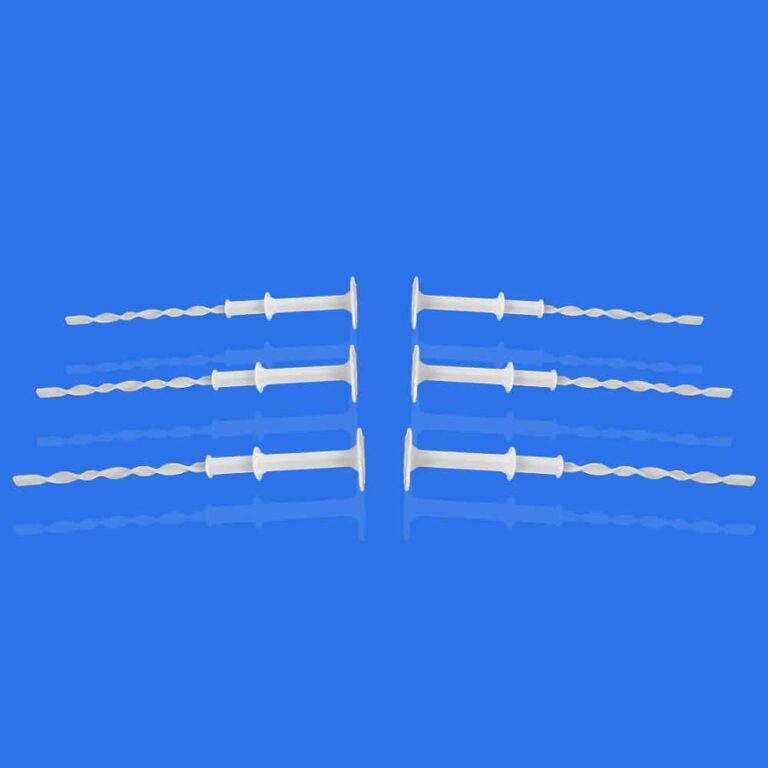

(1) The main working parts in the plastic mold, such as the core, cavity and insert, are used as the assembly reference parts. Other parts of the mold have assembly reference parts for preparation and assembly.

(2) The base plane of the guide post guide sleeve or the template side of the mold shall be taken as the assembly datum plane for trimming and assembly.

2、 Die assembly precision

(1) Mutual operation accuracy of all parts and components, such as distance dimension accuracy, coaxiality, equality, perpendicularity, etc.

(2) Relative motion accuracy, such as transmission accuracy linear motion and rotary motion accuracy.

(3) Fit precision and contact precision, such as fit clearance, interference amount, contact condition, etc.

(4) The wall thickness of plastic formed parts. When making a new die, the wall thickness of formed parts shall deviate from the lower limit of the size.

3、 Repair principle

(1) In principle, the mold cavity shall ensure that the large end size is within the dimensional tolerance of the part. The core shall ensure that the small end size is within the dimensional tolerance of the part.

(2) The radius of the corner corner, the cavity should be smaller, and the core should be larger.

(3) When the mold has both horizontal and vertical parting surfaces, the horizontal parting surface should have a slight gap when the vertical parting surface contacts. The clearance value is > 0.01mm; Small molds only need to be painted with red and then contact each other; The clearance of large die is about 0.02mm.

(4) For the die with inclined plane, after the inclined plane is closed, a clearance of 0.02-0.03mm shall be left at the parting surface.

(5) The connection between the arc and the straight line of the repaired surface shall be smooth, and the surface shall be free of dents. The filing pattern shall be consistent with the mold opening direction.