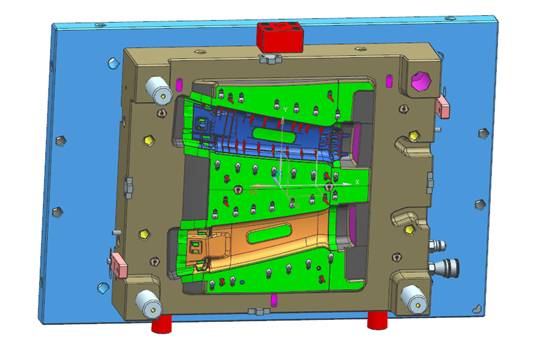

Process characteristics of insert injection molding

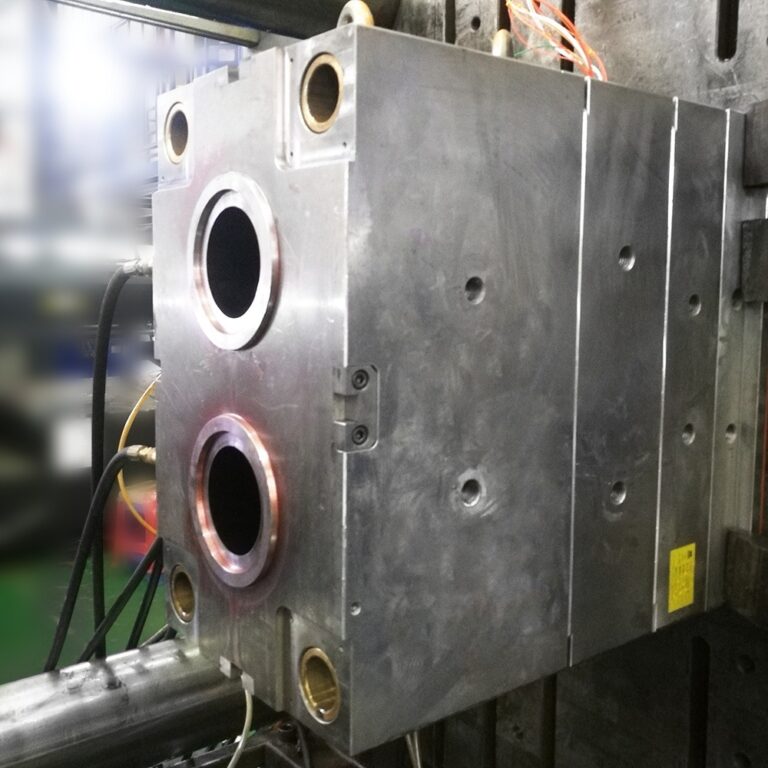

Injection molding of inserts: insert molding refers to the molding process in which pre prepared inserts of different materials are put into the mold and then resin is injected. The molten materials are joined with the inserts and solidified to make an integrated product.

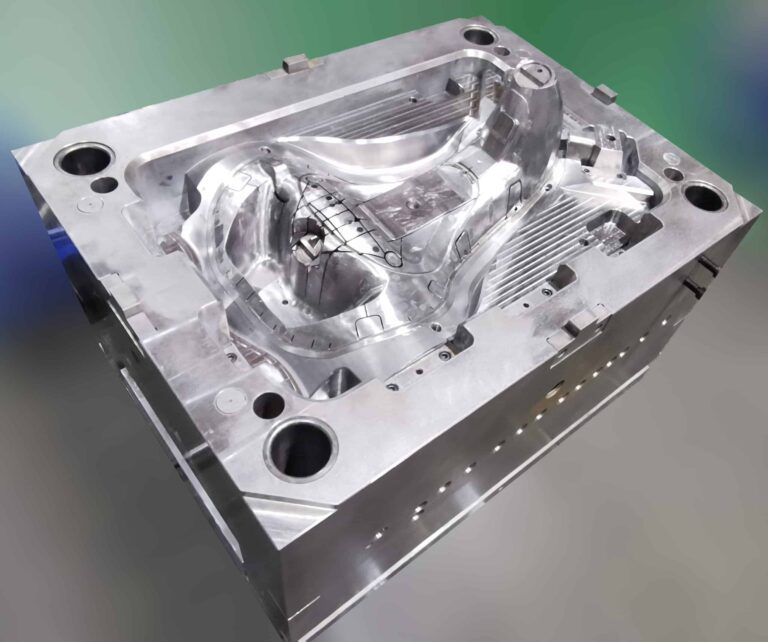

Process characteristics:

1. The pre forming combination of multiple inserts makes the post engineering of product unit combination more reasonable.

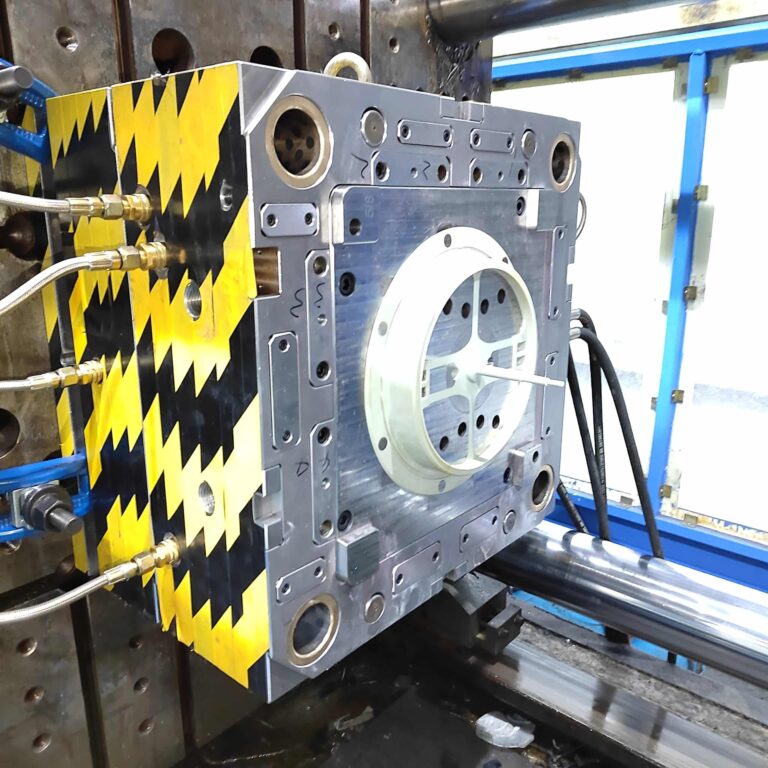

2. The combination of the easy molding and bending properties of resin and the rigidity, strength and heat resistance of metal can solidly make complex and exquisite metal plastic integrated products.

3. In particular, the combination of the insulation of resin and the conductivity of metal is used to make molded products that can meet the basic functions of electrical products.

4. For rigid molded products and bending elastic molded products on rubber sealing pads, the complex operation of arranging sealing rings can be omitted after the integrated products are made by injection molding on the substrate, which makes the automatic combination of the subsequent processes easier.