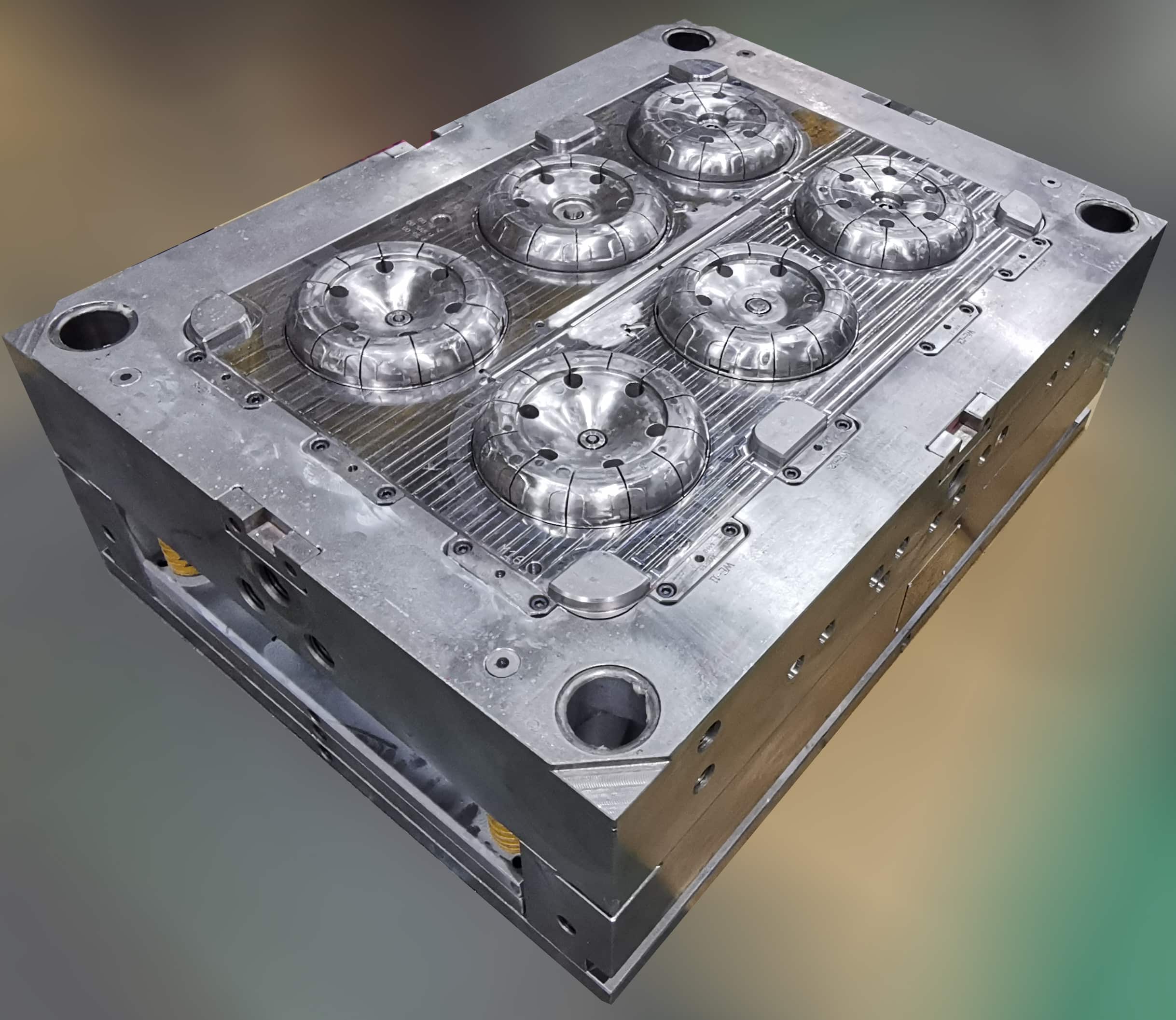

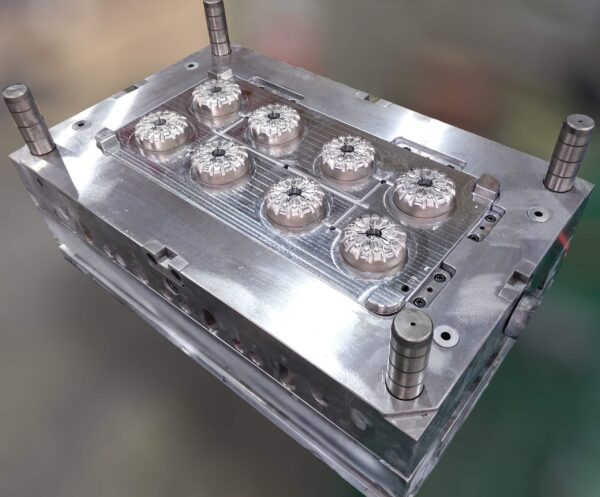

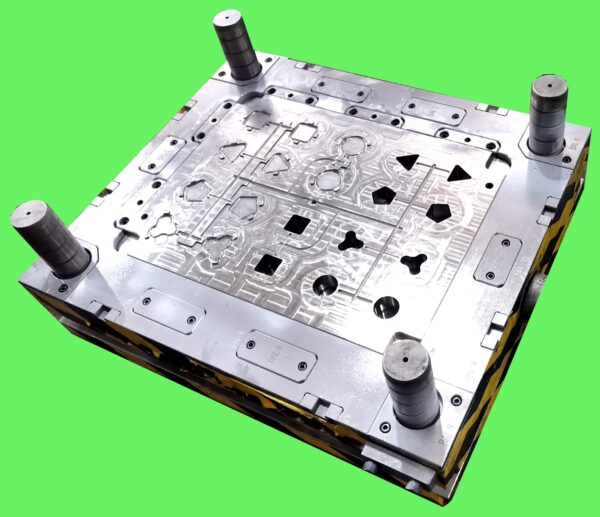

Multi-Cavities Molds

Description

One mold with multiple cavities is usually used in two situations:

1) With large batch of products, multiple cavities mold can produce multiple parts in one

injection cycle to improve efficiency.

2) The parts are small, but only large injection molding machines are available. At this

time, multiple parts can be arranged in one mold for simultaneous production.

| Cavity Material | 1.2738,1.2343, 1.2344, S7, H13, P20HH, GS738H, LKM738H, 718, 8407, S136, Calmax 635 NAK80, SKD-61,NIMAX, 45#, 50#, Aluminum for prototype mold etc. |

| Runner | Cold runner or Hot runner :YUDO/ HUSKY/MOLD-MASTER/SYNVENTIRE/INCOE/ MASTIP/ HASCO/ DME |

| Gate | Submarine gate, tunnel gate, side/edge gate, direct gate, pin point gate, sprue gate, diaphragm gate, fan gate, cashew gate, hook gate, hot tip, hot drop, valve gate etc. |

| Plastic material for parts | PS, SAN, PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE, TPU, TPV etc |

| Process | CNC, high speed carve, EDM ,wiring-cutting, drill, polish etc |

| Lead Time | 10-30 work days depends on the structure and size of products |

| Package | Wooden Case Package or according to customer requirement |

| Price Term | EX Works, FOB Shenzhen, FOB Hong Kong, China, CFR, CIF, DDU, DDP |