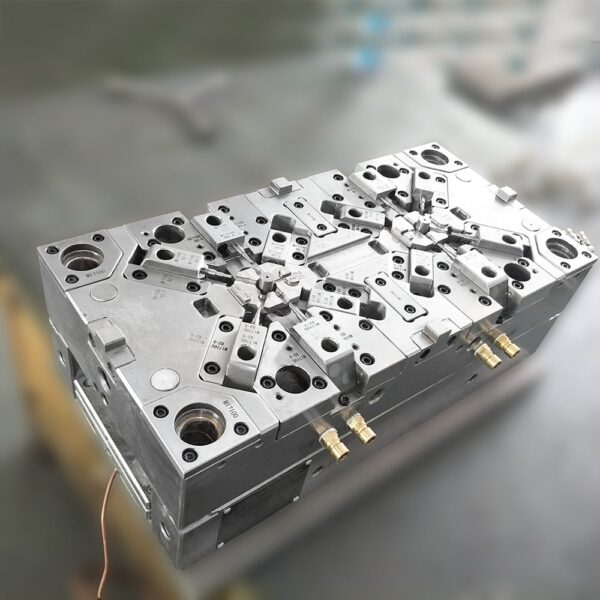

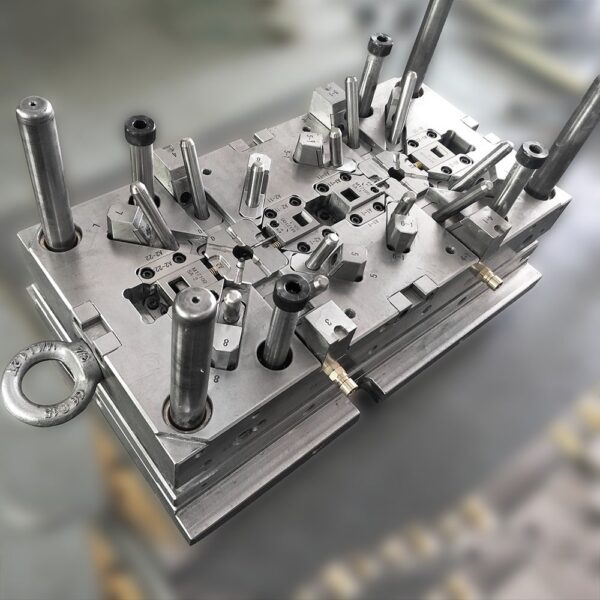

Plastic Injection Mold Multiple-Cavity

Description

Tool Features:

- Complicated mold structure/ Collapsible core .

- Interchangeable inserts to form 2 versions of product

- Good cooling and venting

Part function: Stem Snap-On Housing Components for water supply and drainage system

Mold size: 300*500*306 MM

Mold weight: 270KGS

Injection molding machine size: JSW 55T

Ejector stroke: 25MM

Part material: PP HOMO +10%GF White

Shrink rate: .005” inch/inch

Cavity and core steel: GS738H/ 1.2738 (30-32HRC)

Number of cavities.: 2 Cavity/ Two Cavities

Advantages of Multi Cavity Plastic Mold:

The reason why we manufacture multi cavity plastic molds is very simple. It is to control the unit cost of plastic molding parts production. For example, the production cost of a 160 ton injection molding machine is USD8 per mold. If you use an 8-cavity mold to produce parts, the production cost of each part is USD1. If you only use a 2-cavity mold to produce parts of this machine, the unit production cost is USD4. If you need one million or more parts, You can imagine how much cost can be saved from the 8-cavity mold, which is why the multi cavity mold is so popular with customers.

Disadvantages of Multi Cavity Plastic Mold

We all know that all customers like multi-cavity molds because it can save a lot of production costs. However, other factors need to be considered before making a decision, because manufacturing plastic molds is not cheap, and manufacturing multi-cavity molds is more expensive than single cavity or dual cavity molds.

Plastic Injection Mold Description:

| Cavity Material | 1.2738,1.2343, 1.2344, S7, H13, P20HH, GS738H, LKM738H, 718, 8407, S136, Calmax 635 NAK80, SKD-61,NIMAX, 45#, 50#, Aluminum for prototype mold etc. |

| Runner | Cold runner or Hot runner :YUDO/ HUSKY/MOLD-MASTER/SYNVENTIRE/INCOE/ MASTIP/ HASCO/ DME |

| Gate | Submarine gate, tunnel gate, side/edge gate, direct gate, pin point gate, sprue gate, diaphragm gate, fan gate, cashew gate, hook gate, hot tip, hot drop, valve gate etc. |

| Plastic material for parts | PS, SAN, PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE, TPU, TPV etc |

| Process | CNC, high speed carve, EDM ,wiring-cutting, drill, polish etc |

| Lead Time | 10-30 work days depends on the structure and size of products |

| Package | Wooden Case Package or according to customer requirement |

| Price Term | EX Works, FOB Shenzhen, FOB Hong Kong, China, CFR, CIF, DDU, DDP |