Production Process Characteristics Of Injection Molding Two-color Products

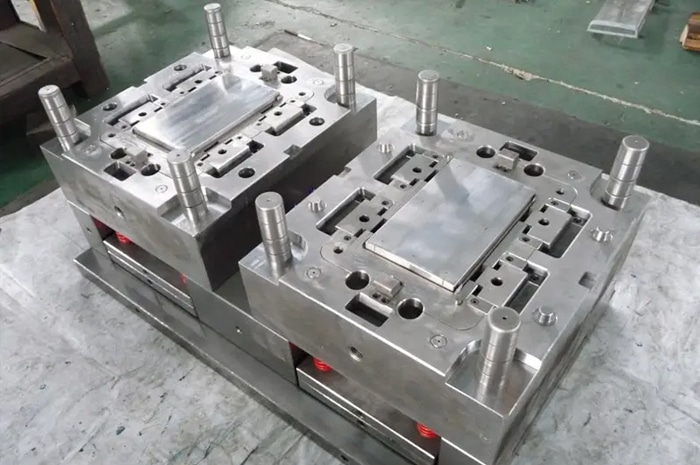

Two-color injection molding usually refers to the molding of two colors or different kinds of plastics. Because the two groups of injection units and nozzles of the two-color machine are independent, the color of the finished product is mostly two-color and distinct, not mixed together. The biggest difference between two-color injection molding machine and general injection molding machine lies in the design of movable template of injection unit machine. Generally speaking, two-color machines have two groups of independent injection units, while general injection machines have only one group of injection units. The configuration of the two groups of injection units has various forms with the design of various manufacturers. As for the design of the movable template, it is necessary to provide a rotating mechanism. Generally, common designs such as adding a turntable or a rotating shaft mechanism can provide the function of 180 reciprocating rotation, so that the mold can produce cyclic alternating movements. Other special two-color molds do not need rotary table or rotating shaft mechanism, but the molds slide alternately or rotate horizontally.

1. Two-color injection molding machine consists of two sets of plasticizing injection devices with identical structure and specifications. According to the production mode, the nozzle should have a special structure, or be equipped with two groups of molding dies with the same structure that can rotate and transpose. During plasticizing injection, it is required that the melt temperature, injection pressure, injection melt quantity and other process parameters in the two plasticizing injection devices are the same, and the fluctuation difference of process parameters in the two devices should be minimized.

2. Compared with ordinary injection molding plastic products, the melt temperature and injection pressure of two-color injection molding plastic products should adopt higher parameter values. The main reason is that the mold runner in two-color injection molding is long, the structure is complex, and the flow resistance of injection melt is large.

3. Two-color injection molding plastic products should be made of raw materials with good thermal stability and low melt viscosity to avoid decomposition due to high melt temperature and long residence time in the runner. Polyolefin resin, polystyrene and ABS are widely used plastics.

4. During the injection molding of two-color plastic products, in order to make two kinds of different colors melt well in the mold and ensure the molding quality of the injection products, higher melt temperature, higher mold temperature, higher injection pressure and injection rate should be adopted.