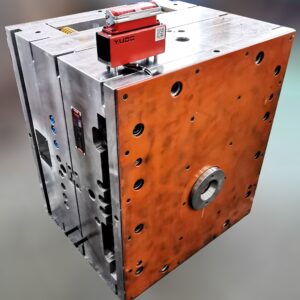

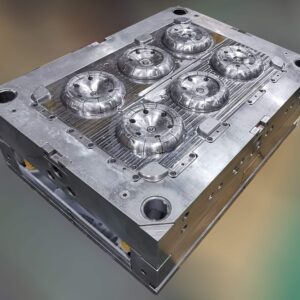

2-Shot / Multi-Material Molds

Two color mold: that is to say, two plastic materials need to be injected on the same injection molding machine for two times respectively, but the product is ejected at one time, which is also called double material injection molding. The double color injection molding machine is completed by a set of molds. The products…