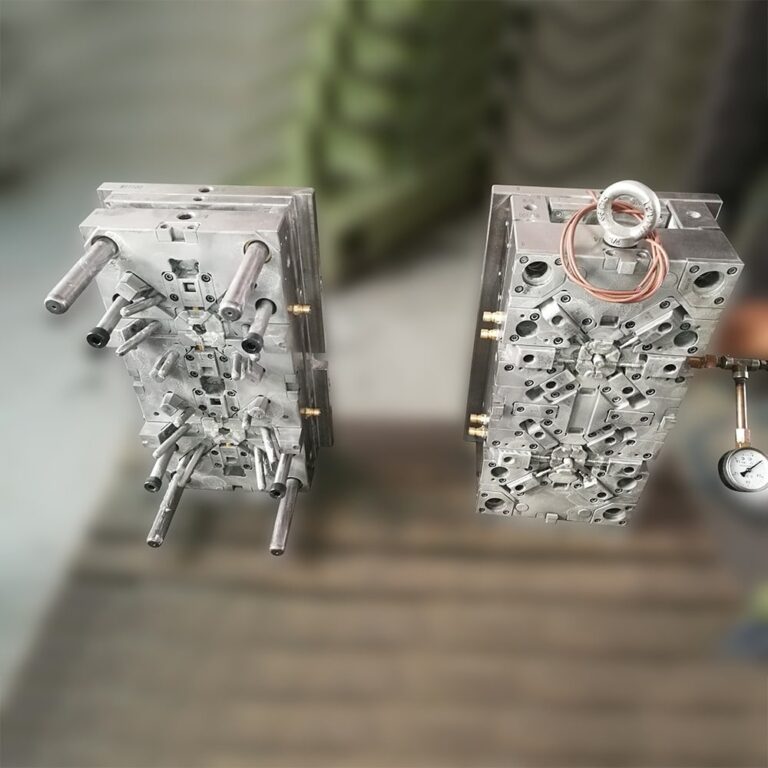

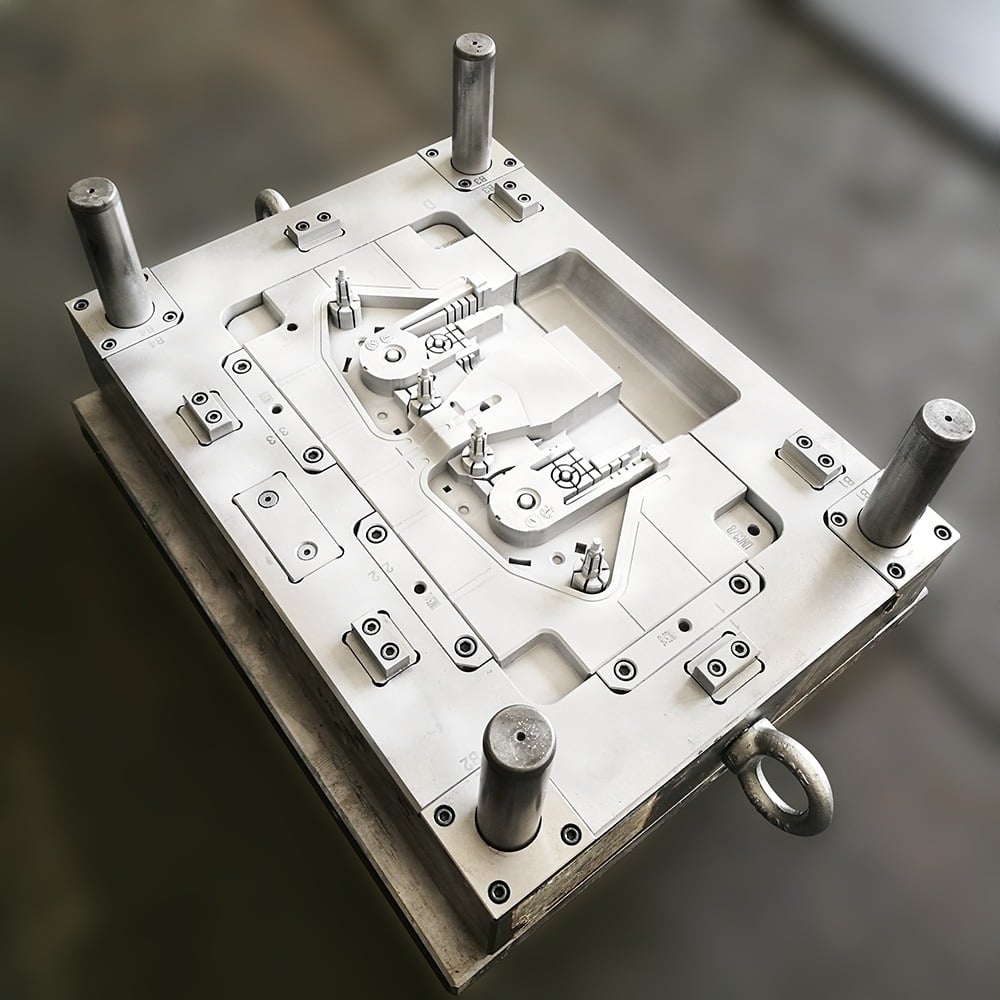

Rust causes of injection mould and solutions:

As we all know, injection molds are mainly made of tool steel. During work, they will encounter corrosive gases, water and other substances that cause rust. Plastic parts made of rusty molds often have quality problems, so we must find out the causes of rust in the molds and solve them.

Reason 1: When the mold raw materials are overheated, they will produce volatile gases, which are mostly corrosive. When the mold is not working, they will diffuse around the mold, causing rust.

Solution: When the mold stops working, the operator should use a soft cloth to clean the mold. If the mold is not used for a long time, the mold cavity should also be sprayed with anti rust agent.

Reason 2: In the cooling process of the mold, the water in the surrounding air will form water drops on the mold surface. If it is not wiped in time, it is easy to rust.

Solution: Shut down the cooling water system and dry the mold in time after the mold stops processing.

Injection mold is an important process equipment for producing various industrial products. With the rapid development of the plastic industry and the promotion and application of plastic products in aviation, aerospace, electronics, machinery, shipbuilding and automotive industries, the demand for injection mold in various industries has greatly increased.