Selection Technique of Gate Position for Automobile Die

1. Place the gate at the thickest part of the product, and pouring from the thickest part can provide better filling and pressure maintaining effect. If the pressure is insufficient, the thinner area will solidify faster than the thicker area, so as to avoid placing the gate at the sudden change of thickness, so as to avoid the occurrence of hysteresis or short shot.

2. If possible, pouring from the center of the product and placing the gate in the center of the product can provide an equal length of flow length. The size of the flow length will affect the required injection pressure. The central pouring makes the pressure maintaining pressure in all directions uniform, which can avoid uneven volume shrinkage.

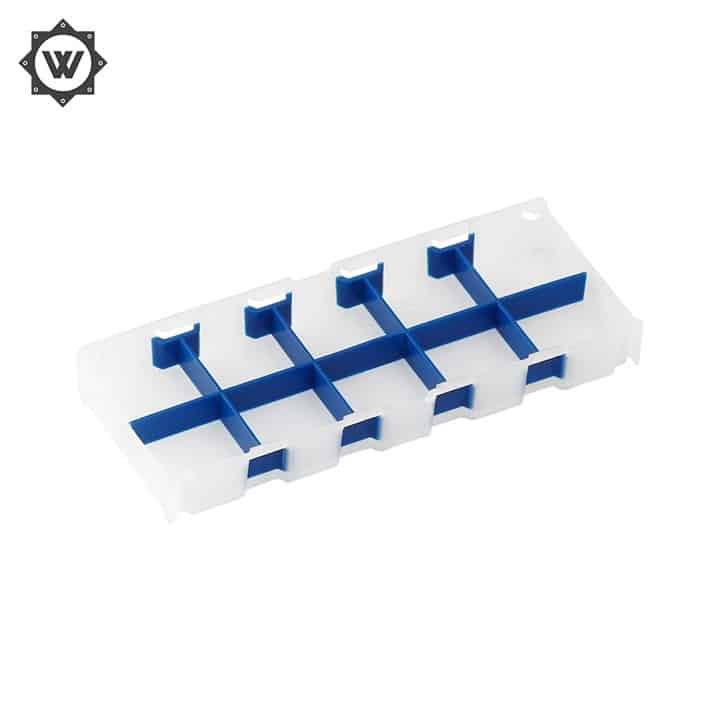

3. Gate: The gate is a short groove with small cross-sectional area, which is used to connect the runner and mold cavity. The cross-sectional area should be small so as to achieve the following effects:

1) The gate will be cold formed soon after the mold cavity is injected

2) Simple water outlet

3) The water outlet is completed, leaving only a few traces

4) Make the packing of multiple mold cavities easier to control

5) Reduce excessive filler

There are no hard and fast rules for gate design methods. Most of them are based on experience, but there are two basic elements that need to be compromised:

1. The larger the cross-sectional area of the gate, the better, while the shorter the length of the channel, the better, to reduce the pressure loss when the plastic passes through WeChat of mold expert: mujudaren

2. The gate must be thin and narrow, so that it is easy to cold knot and prevent excessive plastic backflow. Therefore, the gate is in the center of the runner, and its cross section should be as round as possible. However, the switch of the gate is usually determined by the switch of the module

3. Gate size:

The gate size can be determined by the cross-sectional area and gate length. The following factors can determine the optimal gate size:

1) Rubber flow characteristics

2) Thickness of module

3) Amount of rubber injected into the mold cavity

4) Melting temperature

5) Mold temperature

When determining the gate position, the following principles shall be followed:

1. The rubber injected into each part of the mold cavity shall be as even as possible

2. The rubber injected into the mold shall maintain a uniform and stable flow front at all stages of the injection process

3. Possible welding marks, bubbles, cavities, virtual positions, insufficient glue injection and glue spraying shall be considered

4. The water outlet shall be easy to operate, preferably automatically

5. The position of gate shall match with all aspects