During injection molding, there will not be a lot of molten materials oozing from the vent hole, because the molten materials will be cooled and solidified there to block the channel. The opening position of the exhaust port shall not face the operator to prevent accidental ejection of molten materials from injuring people. In addition, the fit clearance between the ejector rod and the ejector hole, the fit clearance between the ejector block and the stripper plate and the core can also be used to exhaust.

1. Function of exhaust slot

There are two main functions of the exhaust slot:

When injecting molten materials, the air in the mold cavity is discharged;

All kinds of gases generated during the heating process of materials are eliminated.

The more thin-walled products, the farther away from the gate, the opening of the exhaust slot is particularly important.

In addition, for small parts or precision parts, attention should also be paid to the opening of exhaust grooves, because it can not only avoid surface burns and insufficient injection volume of products, but also eliminate various defects of products and reduce mold pollution.

Then, how can the mold cavity be fully vented? Generally speaking, if the molten material is injected at the highest injection rate, but no coke spot is left on the product, it can be considered that the air exhaust in the mold cavity is sufficient.

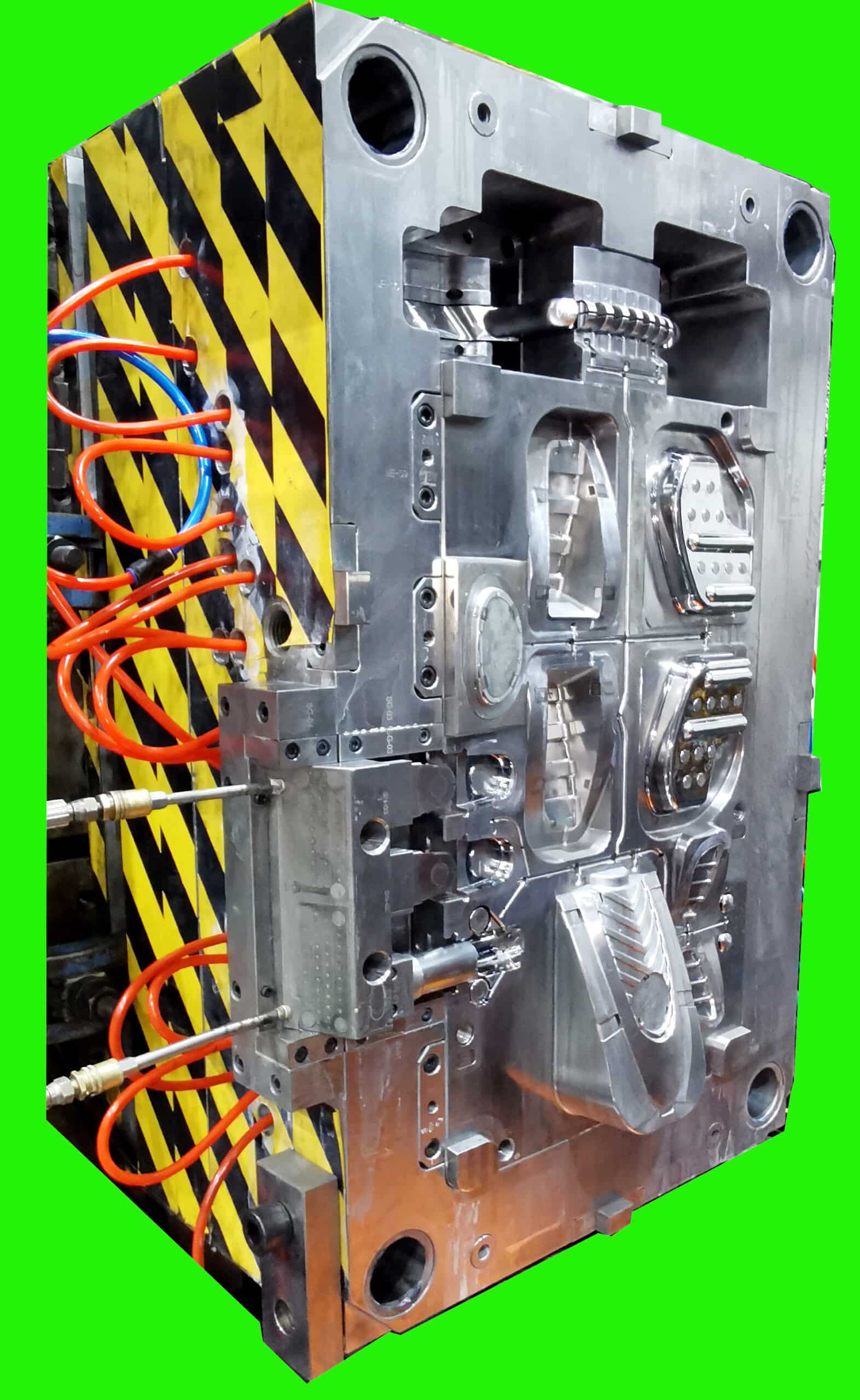

2. Exhaust mode

There are many methods to exhaust the mold cavity, but each method must ensure that: the size design of the exhaust slot should prevent materials from overflowing into the slot while exhausting; Second, prevent clogging.

Therefore, when measuring from the surface of the mold cavity to the outer edge of the mold cavity, the height of the exhaust slot with a length of 6-12mm or more should be about 0.25-0.4mm. In addition, too many exhaust grooves are harmful. Because, if the clamping pressure acting on the parting surface of the mold cavity without the vent slot is very large, it is easy to cause cold flow or crack of the mold cavity material, which is very dangerous.

In addition to venting the mold cavity on the parting surface, the purpose of venting can also be achieved by setting an exhaust slot at the end of the material flow of the gating system and leaving a gap around the ejector rod. Because the selection of the depth, width and position of the exhaust slot will affect the beauty and accuracy of the products if the flash burrs are not appropriate. Therefore, the above clearance shall be limited to prevent flash around the ejector rod.

Special attention shall be paid here: when venting, even the smallest flash may not be expected. The following methods are preferred for this kind of products:

Completely remove the gas in the flow passage;

The fitting surface of the parting surface shall be shot blasted with 200 # silicon carbide abrasive.

In addition, an exhaust slot is set at the end of the material flow of the gating system, which mainly refers to the exhaust slot at the end of the splitter channel. Its width should be equal to the width of the splitter channel, and its height depends on the material.

3. Design method

For product molds with complex geometry, it is better to determine the opening of the exhaust slot after several mold trials. The biggest disadvantage of the integral structure in the mold structure design is poor exhaust.

For the integral cavity core, there are several exhaust methods as follows:

Use the groove or insert installation position of the cavity;

Use the side insert joint;

Locally made into a spiral shape;

Install the strip center with groove and open the process hole in the longitudinal position;

When it is very difficult to exhaust, the mosaic structure shall be adopted; If it is not easy to open the exhaust slot in the dead corner of some molds, first of all, the molds should be appropriately changed to inlay processing without affecting the appearance and accuracy of the products. This is not only conducive to processing the exhaust slot, but also can improve the original processing difficulty and facilitate maintenance.

4. Conclusion

Properly setting the exhaust slot can greatly reduce the injection pressure, injection time, pressure holding time and clamping pressure, making the molding of plastic parts from difficult to easy, thus improving production efficiency, reducing production costs and reducing the energy consumption of the machine.