Solutions to common overmold injection defects

Lack of glue – increase the processing and injection molding temperature; Increase injection pressure; Improve material flow.

Splitting and overflow – reduce the injection temperature; Increase the clamping force; Reduce injection pressure; Reduces fluidity from the formulation point of view.

The surface is pitted and not bright – increase the injection molding processing temperature; Bake materials to reduce moisture of raw materials.

Poor viscosity – sufficient drying before injection molding; Increase injection temperature; Adjust the recipe.

Injection molding deformation of products – strengthen mold cooling; Properly extend the clamping time.

Sticking of products – add release agent or lubricant (for internal lubricant – pay attention to the amount of release agent to prevent release agent precipitation and migration.

1. Sufficient injection temperature. For rubber coated nylon and TPE, the injection temperature should be above 190 ℃, or not more than 240 ℃. In particular, it is necessary to obtain the effect of real overmold, because the softening temperature of nylon is 250-260 degrees. The closer the softening temperature of TPE and nylon is, the better the overmold effect is.

2. The structure of the overmold part of the product shall be designed as smooth as possible without obvious edges and corners, so as to increase the contact tightness between TPE and nylon hard glue.

3. Open some small holes on the unimportant positions of the nylon skeleton piece, or make some unsmooth surfaces, increase the contact area between TPE and nylon, so that TPE soft glue can be embedded into the nylon skeleton material through the small holes, playing a hoop effect. In fact, it is a combination of real package and fake package effects.

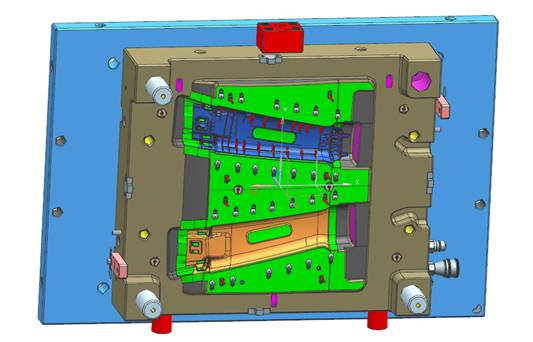

4. For the newly opened mold, attention should be paid to the design of the mold gate and runner. Since the TPE adhesive coating is generally thin, with a thickness of 1-2mm, and the size of the adhesive coating is generally tens or even hundreds of mm, it must be ensured that the TPE soft adhesive can fill the mold cavity, without lack of adhesive or splitting, and ensure the adhesion between TPE and nylon.