Standards for testing hot runner systems for plastic moulds

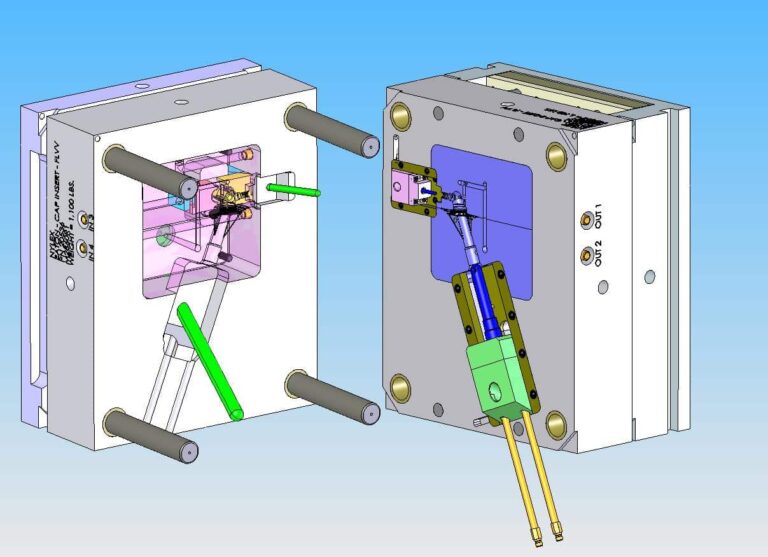

The hot runner is heated to ensure that the plastic in the runner and gate remains molten, the hot runner system is generally composed of hot nozzles, manifolds, temperature control boxes and accessories, etc. The hot nozzles generally include two types: open hot nozzles and needle valve hot nozzles, as the form of hot nozzles directly determines the choice of hot runner system and the manufacture of moulds, and therefore often correspondingly divided into open hot runner system and Needle valve hot runner system.

Plastic mould hot runner system design and processing after how to test it, we can from the following points to test its performance and conformity:

1. hot runner wiring layout should be reasonable, easy to access, wiring number should correspond to one by one.

2. the hot runner should be tested for safety, insulation resistance to ground is greater than 2MW.

3. temperature control cabinet and hot nozzle, hot runner should be standard parts.

4. The main flow port sleeve is connected to the hot runner with threads and the bottom surface flat contact seal.

5. The hot runner is in good contact with the heating plate or heating rod, and the heating plate is fixed with screws or studs with a good surface fit.

6. J-type thermocouples should be used and matched to the temperature control meter.

7. each group of heating elements should have thermocouple control, and the thermocouple position is reasonably arranged.

8. the nozzle should meet the design requirements.

9. the hot runner should be reliably positioned, with at least two positioning pins, or screwed in place.

10. Heat insulation pads should be provided between the hot runner and the template.

11. the temperature control table set temperature and the actual display temperature error should be less than ± 5 ° C, and temperature control sensitive.

12. the cavity and the nozzle installation hole should be penetrated.

13. the hot runner wiring should be tied and covered with a pressure plate.

14. two sockets of the same size should be clearly marked.

15. The control wires should be sheathed and undamaged.

16. The temperature control cabinet is structurally sound and has no loose screws.

17. The socket is mounted on the bakelite and does not exceed the maximum size of the formwork.

18. the electric wire is not exposed outside the mould.

19. all contact points between the hot runner or the formwork and the wires should have rounded corners.

20. all wiring is free from short-circuiting before the formwork is assembled.

21. all wiring should be properly connected and well insulated.

22. All wiring should be checked again with a multimeter after the formwork has been clamped on.