Structure composition and classification of injection mold push-out mechanism

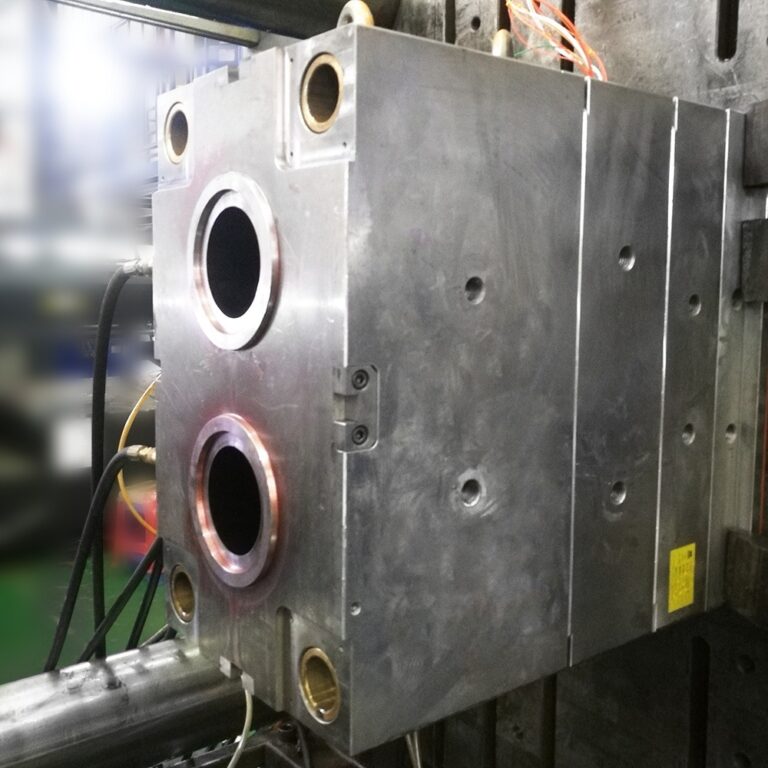

Before the injection parts are removed from the injection mold, there is a process of releasing the molded parts from the injection mold. The action of the push-out mechanism is done by the top bar or hydraulic cylinder mounted on the mold closing mechanism of the injection molding machine.

(A) the composition of the launch mechanism

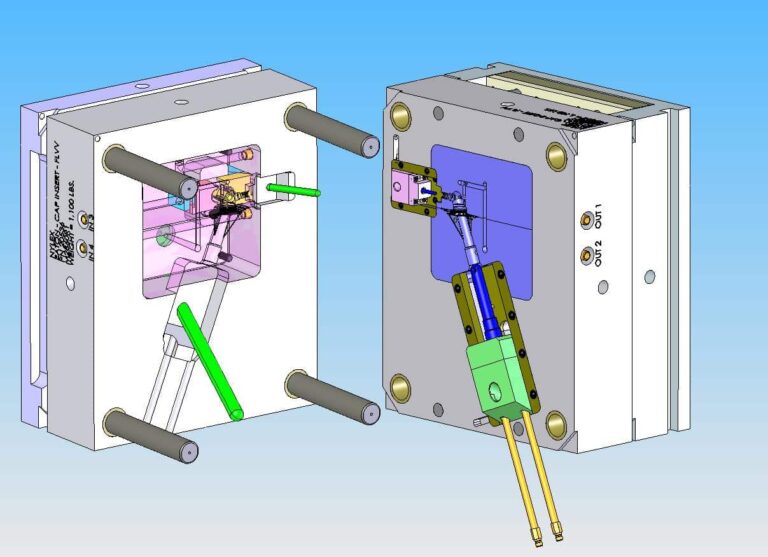

In the injection mold, the push out mechanism is composed of push rod, pull rod, push rod fixed plate, push plate, push plate guide column, push plate guide sleeve and reset rod. When the mold is opened, the movable part of the mold moves to the left. After the mold is opened for a certain distance, when the top bar of the injection machine touches the push plate of the injection mold, the push rod, the pull rod, together with the push rod fixing plate and the push plate, will be stationary, and when the movable part of the mold continues to move to the left, the plastic part will be pushed out from the convex mold by the push rod.

The design principles of the injection mold launch mechanism, launch mechanism, where direct contact with the plastic parts, and the plastic parts out of the cavity or core parts called launch parts. Commonly used push out parts are push rod, push tube, push piece plate, molding push rod, etc., push rod. Push rod fixed and push the plate by the screw connection, used to fix the launch parts. In order to ensure the launch of parts, after the mold can return to the original position, need to set the reset mechanism, for the reset lever. Push out mechanism, from the point of view of ensuring a smooth and flexible push out, usually also has a guide device, for the push plate guide column and push plate guide bush. In addition, there is also a pulling rod to ensure that the main stream of the pouring system is pulled out from the gate sleeve of the fixed mold and left on the side of the moving mold. Some injection molds are also equipped with support pegs to form a gap between the push plate and the base plate, which is easy to ensure the flatness requirements and is conducive to the removal of waste and debris, in addition, the thickness of the support pegs can be adjusted to control the launch distance.

(B) the introduction of the classification of institutions

The launch mechanism can be divided into manual launch mechanism, motorized launch mechanism, hydraulic and pneumatic launch mechanism according to the power source of the launch action. The manual push-out mechanism is used to push out the plastic parts by the manually operated push-out mechanism after the injection mold is opened, which is generally used in the case that the plastic parts are left on the side of the fixed mold; the motorized push-out mechanism uses the opening action of the injection machine to drive the push-out mechanism on the injection mold to realize the automatic release of the plastic parts; the hydraulic and pneumatic push-out mechanism relies on the special hydraulic and pneumatic devices set on the injection machine to push out or blow out the plastic parts from the injection mold. The hydraulic and pneumatic push-out mechanism relies on special hydraulic and pneumatic devices installed on the injection machine to push out or blow out the plastic parts from the injection mold. Push-out mechanism can also be classified according to the type of parts to be pushed out, which can be divided into push rod push-out mechanism, push tube push-out mechanism, push part plate push-out mechanism, concave mold or molding push-out mechanism, multiple integrated push-out mechanism and so on. In addition, it can also be classified according to the structural characteristics of the mold, such as simple push out mechanism, movable and fixed mold push out mechanism, sequential push out mechanism, secondary push out mechanism, casting system condensate release mechanism, and the release mechanism of the mold with threaded plastic parts, etc.