Summary of Die Technology for Side Plate of Air Conditioner Condenser

1.Condenser side plate product introduction

Condenser side plate is one of the most common parts in air conditioning mold manufacturing products. Therefore, the mold has high requirements for design, short manufacturing cycle and high production efficiency; It is an important and only part for connecting radiator in air conditioning mold manufacturing.

2.The dimension requirements of condenser side plate products are as follows:

(1) The size of the hole diameter for flanging is required to be high, and the tolerance within 0.05MM must be guaranteed. Only in this way can we ensure that the dimensional requirements of threading and the requirements of air conditioner die manufacturing and assembly are met after pipe expansion

(2) The requirements for bud diameter and height at the side are high. So as to ensure the fastening of the connecting piece of this part

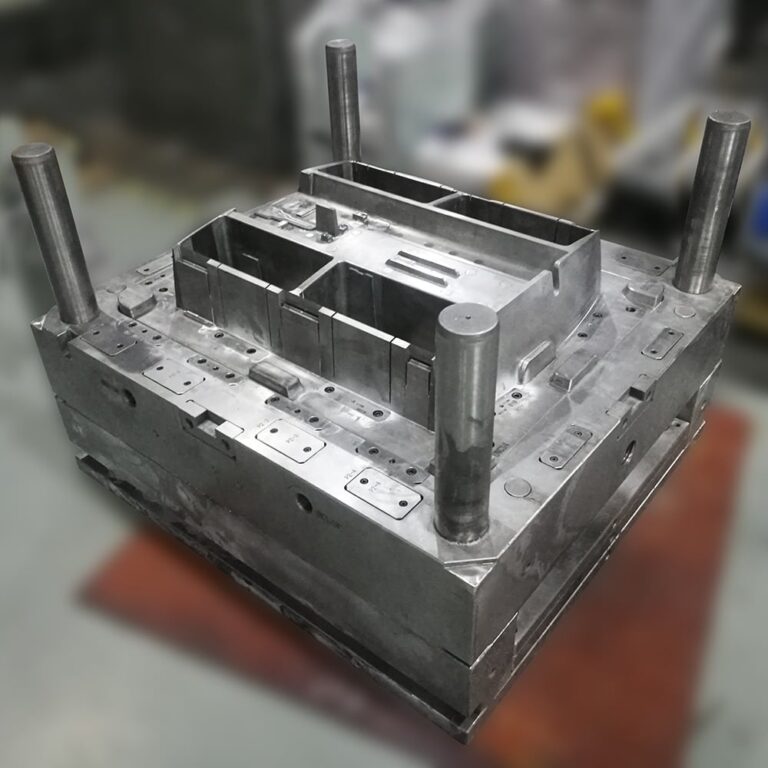

3.Summary of die technology for condenser side plate

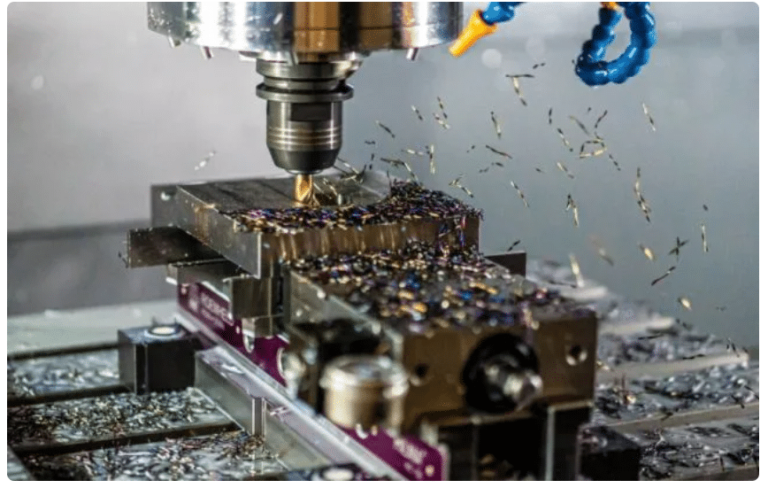

(1) Such products are generally made into continuous die structures. Finished products are completed through punching, flanging, forming and cutting processes. Continuous use can effectively improve production efficiency

(2) The difficulty of the die is mainly in the punching and flanging process. On the one hand, ensure the dimensions of all punches and the clearance between male and female dies; On the other hand, it should be convenient to repair the mold and maintain it.