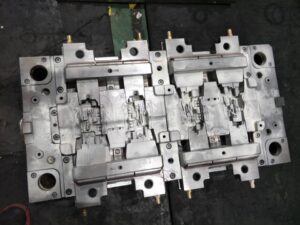

Several Factors That Determine The Price Of Mould

Several factors that determine the price of mould. Mould is also a commodity. The common requirements of objective conditions for moulds, that is, the technical and economic indicators of moulds, can be summarized in four aspects: the precision and rigidity of moulds, the production cycle of moulds, the production cost of moulds and the life of moulds. In all aspects of the mold manufacturing process, attention should be paid to the four requirements of