The basic process of injection molding mold design

After a clear understanding of the plastic products to be produced, you can start to design a specific mold program, the specific design process is as follows.

(1) Factors to be determined before design

The factors to be determined before design include the type of plastic to be used and the shrinkage rate of the mold, the allowable tolerance range of the product and the appropriate release slope, the parameters of the injection molding machine, the number of cavities to be used in the injection mold and the production cost of the injection mold, etc.

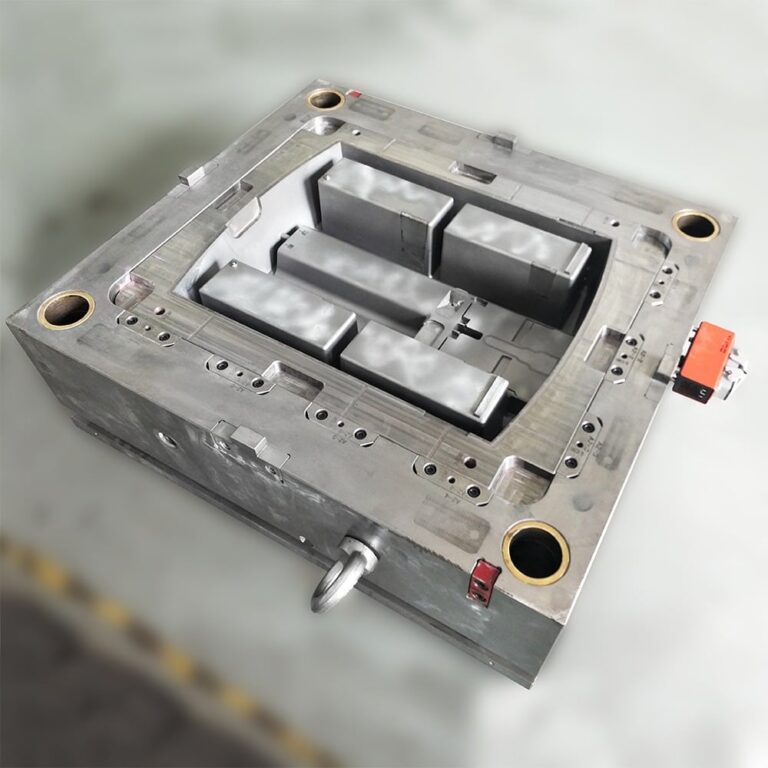

(2) Determine the basic structure of the injection mold

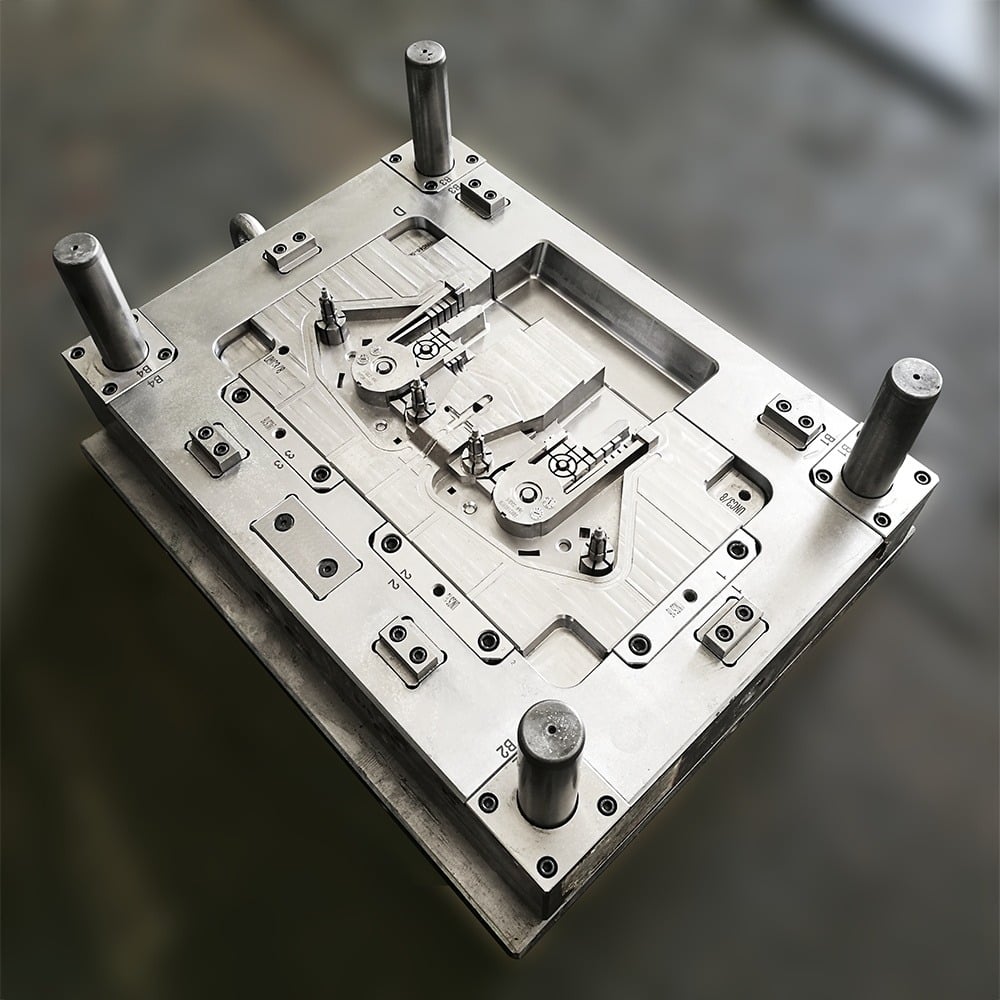

Based on the known factors, we determine the dimensions of the designed injection mold, choose the reasonable parting surface of the product, determine the type of pouring system to be used in the injection mold, determine the way of pushing out the plastic product from the mold and the basic composition of the mold cavity. In determining the basic structure of the mold, we should also consider whether the mold cavity adopts lateral parting mechanism, whether the mold cavity is combined, the cooling method of the mold cavity and the discharge of gas in the mold cavity.

(3) Determine the standard parts used in the injection mold

In the injection mold design, we should choose as many standard parts as possible, including standard mold frame, template, standard guide pillar, guide sleeve, gate sleeve and push rod, etc.. The use of standard parts can improve the precision of injection mold manufacturing, shorten the mold production cycle, and reduce production costs.

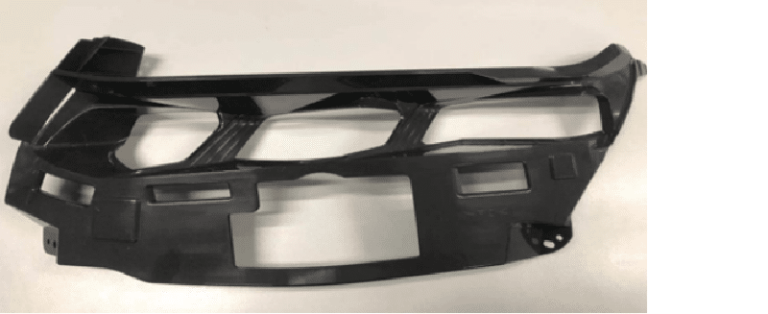

(4) Determine the molding size of the mold cavity in the injection mold

According to the basic size of the plastic parts, use the molding size formula to determine the molding size of each part of the injection mold cavity.

(5) Determine the materials used in the injection mold and perform the necessary strength and stiffness checks.

According to the strength and stiffness calibration formula, the strength and stiffness of the parting surface, cavity, core, support plate and other mold parts can be checked to ensure that they meet the requirements of use.

(6) Complete the design drawings of the injection mold pattern

This includes the assembly drawing of the injection mold design and the mold processing parts drawing. In determining the design of injection mold, in order to improve efficiency, we can use the method of “analogy”, that is, the mold structure of similar products previously designed and manufactured is applied to the mold structure of new products, which can simplify the design process.