The design principle of injection mold launch mechanism

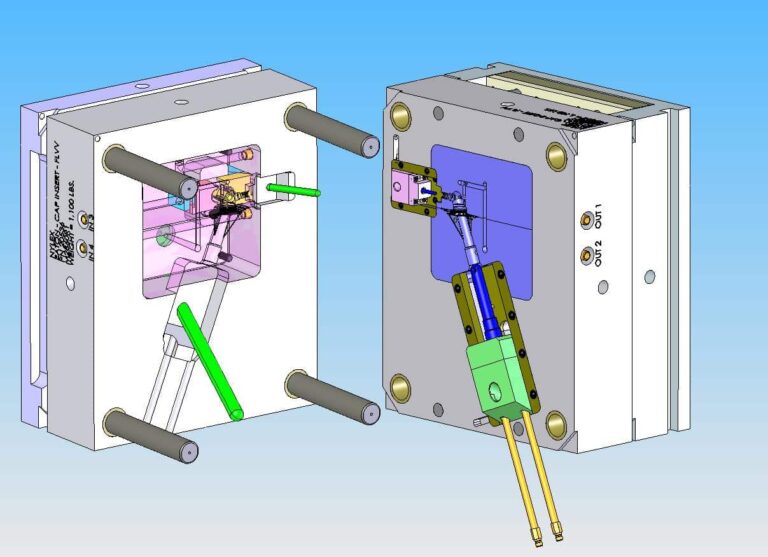

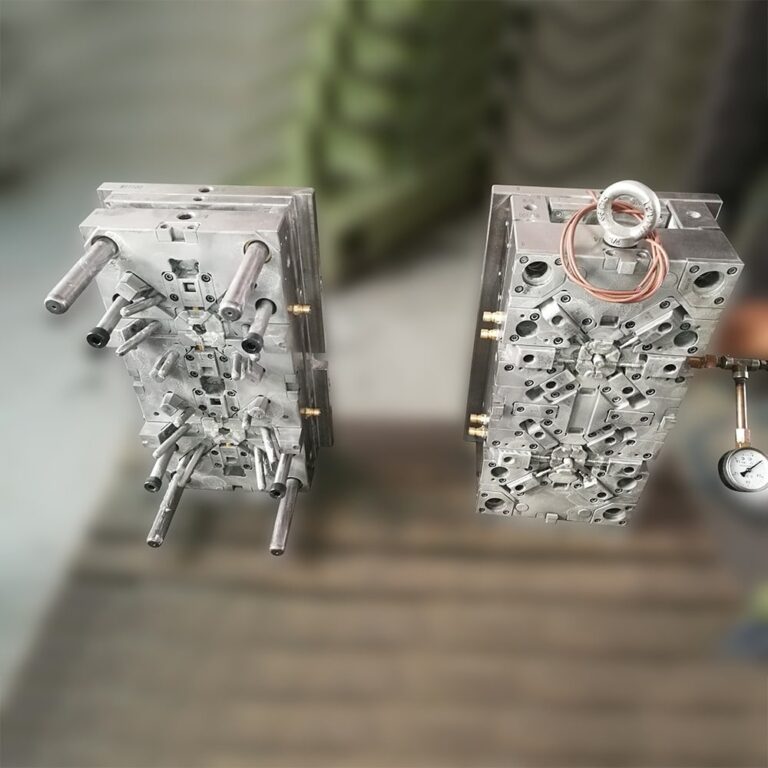

(1) Push out mechanism should be set on the side of the moving mold as far as possible: Since the action of the push out mechanism is driven by the top bar installed on the injection molding mechanism, in general, the push out mechanism is located on the side of the moving mold. Because of this, the parting surface should be designed in such a way that the molded part can stay on the side of the moving mold after opening the mold.

(2)To ensure that the plastic part is not deformed and damaged by the launch: Dongguan Machico Injection Mould Factory, in order to ensure that the plastic part is not deformed and damaged during the launch, the design should carefully analyze the size of the clamping force and adhesion force of the plastic part to the injection mould, and reasonably choose the launch mode and launch position, so that the plastic part is evenly stressed, not deformed and not damaged.

(3) Simple and reliable mechanism: the launch mechanism should make the launch action reliable, flexible and easy to manufacture, the mechanism itself should have sufficient strength, rigidity and hardness to withstand the role of various forces in the launch process, to ensure the smooth release of the plastic parts.

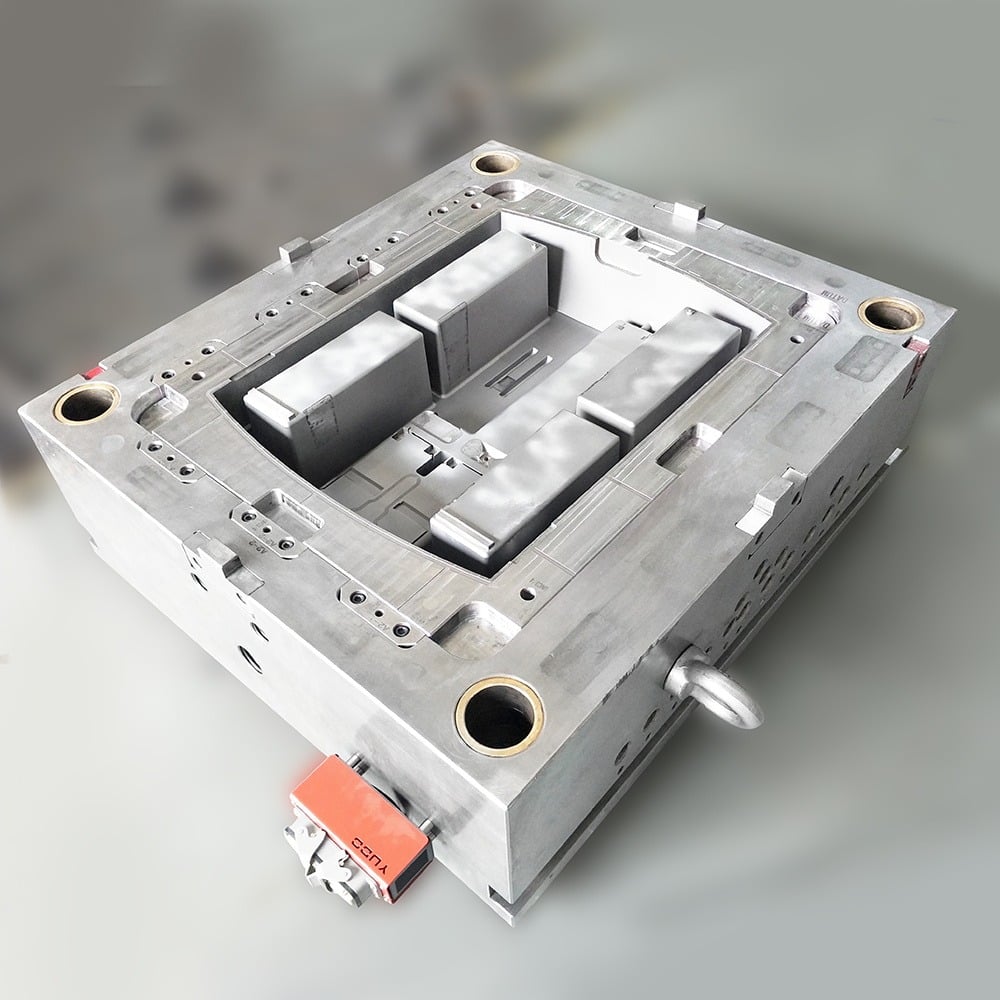

(4) Good appearance of the plastic part: the location of the plastic part should be located inside the plastic part as far as possible, so as to avoid the introduction of traces affecting the quality of the appearance of the plastic part.

(5) The correct reset when closing the mold: When designing the launch mechanism, we must also consider the correct reset of the mechanism when closing the mold, and ensure that it does not interfere with other injection mold parts.