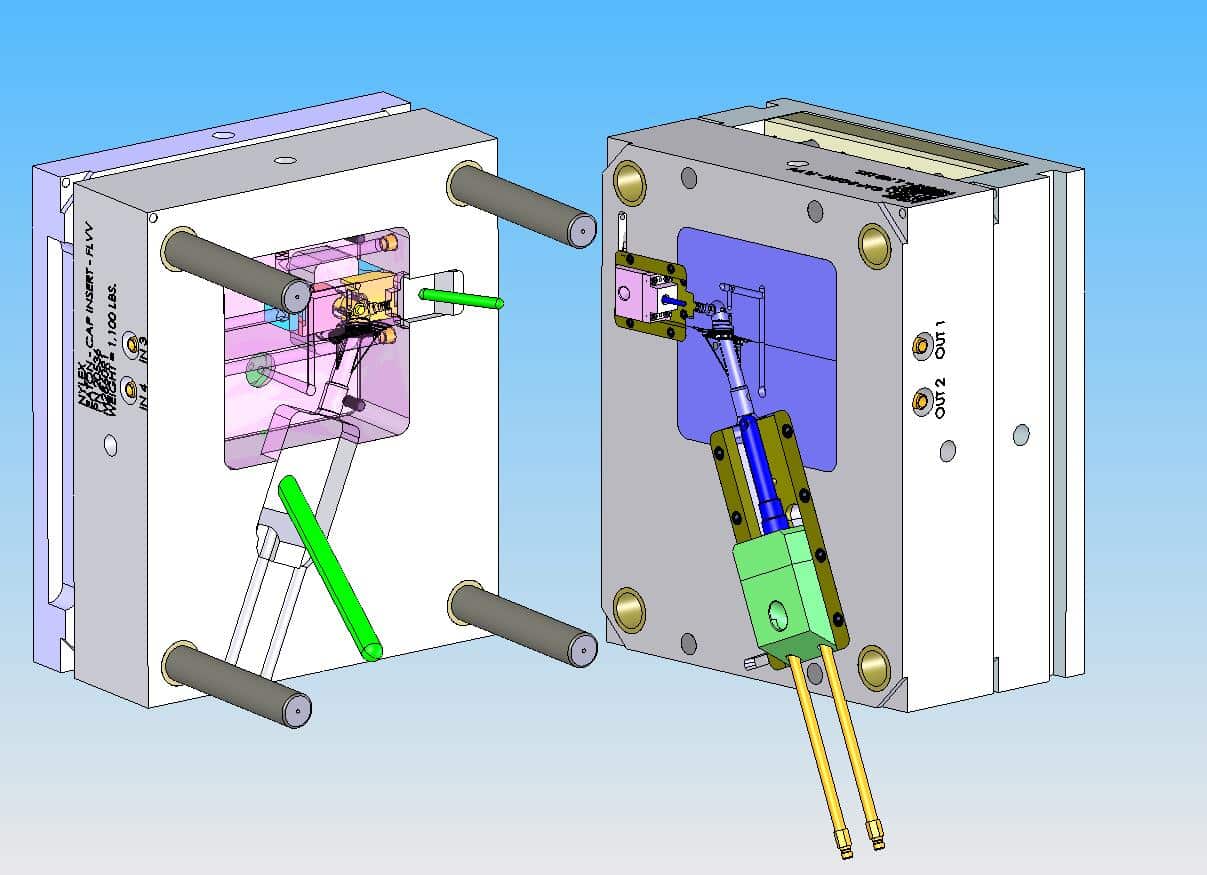

For the automobile lamp reflector mold, the main design points are:

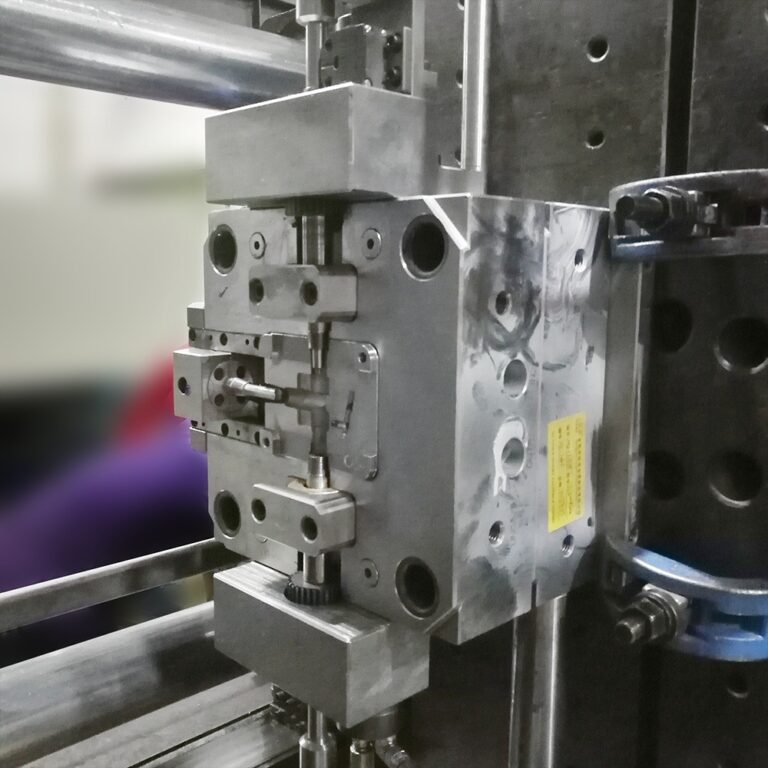

(1) Special injection molding process equipment is required, and injection molding machines specialized in producing BMC plastics are used. The requirements for injection molding process equipment are very strict.

(2) BMC material belongs to super hard plastic. In mold design, heating system and parting surface layout system need to be designed. Molding parts must be quenched to improve wear resistance and mold life.

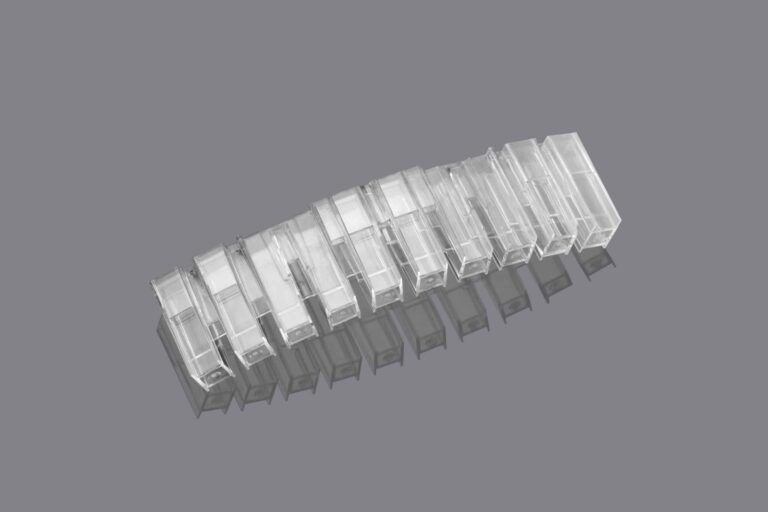

(3) The reflector plastic part is a device for preventing the direct light, reflecting the light and avoiding the direct light on the car lamps, and the light distribution requirements are strict. Plastic parts are the most important appearance parts of automobiles. There are many patterns on the surface of plastic parts for the purpose of decoration and beauty.

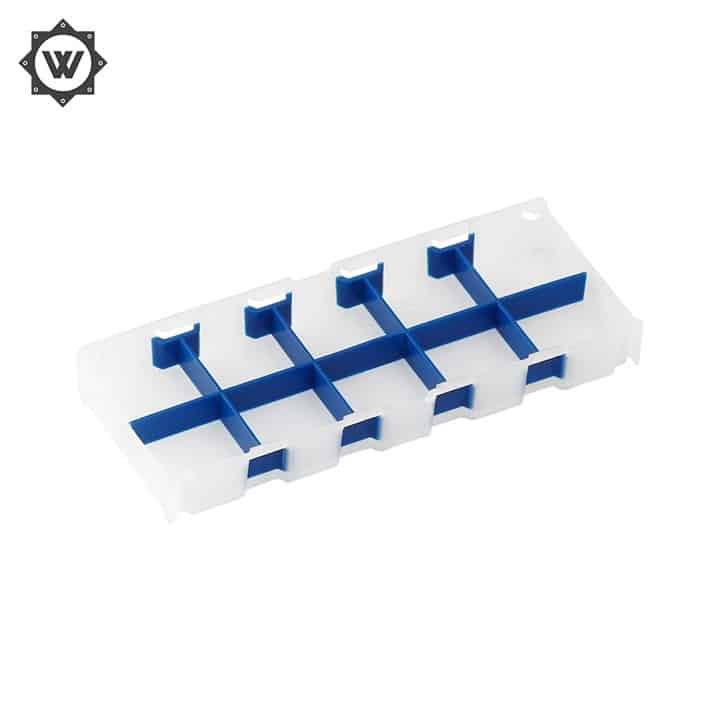

(4) The ejection system of BMC material mold design shall be balanced, and the push rod specification shall be designed as large as possible and the number shall be as large as possible, otherwise it will cause difficulty in demoulding plastic parts.

(5) Because it is difficult to demould the high photoelectric plated parts because the demoulding slope is too small, the side wall demoulding slope of the mirror plastic parts should be designed as large as possible, generally recommended to be 5 °~10 °. Of course, the premise is that the function and shape of the plastic parts cannot be affected.

(6) Plastic parts shall not have sharp corners and sharp edges, and all corners shall be designed as rounded corners, because the formed parts of the die are prone to stress cracking after quenching.

(7) Note that the left and right reflector lamp cap holes and the pattern on the surface of the plastic parts are translated from side to side, and cannot be designed to be mirror symmetrical, because the bulb and lamp cap are not left and right, and the other features are mirror symmetrical.