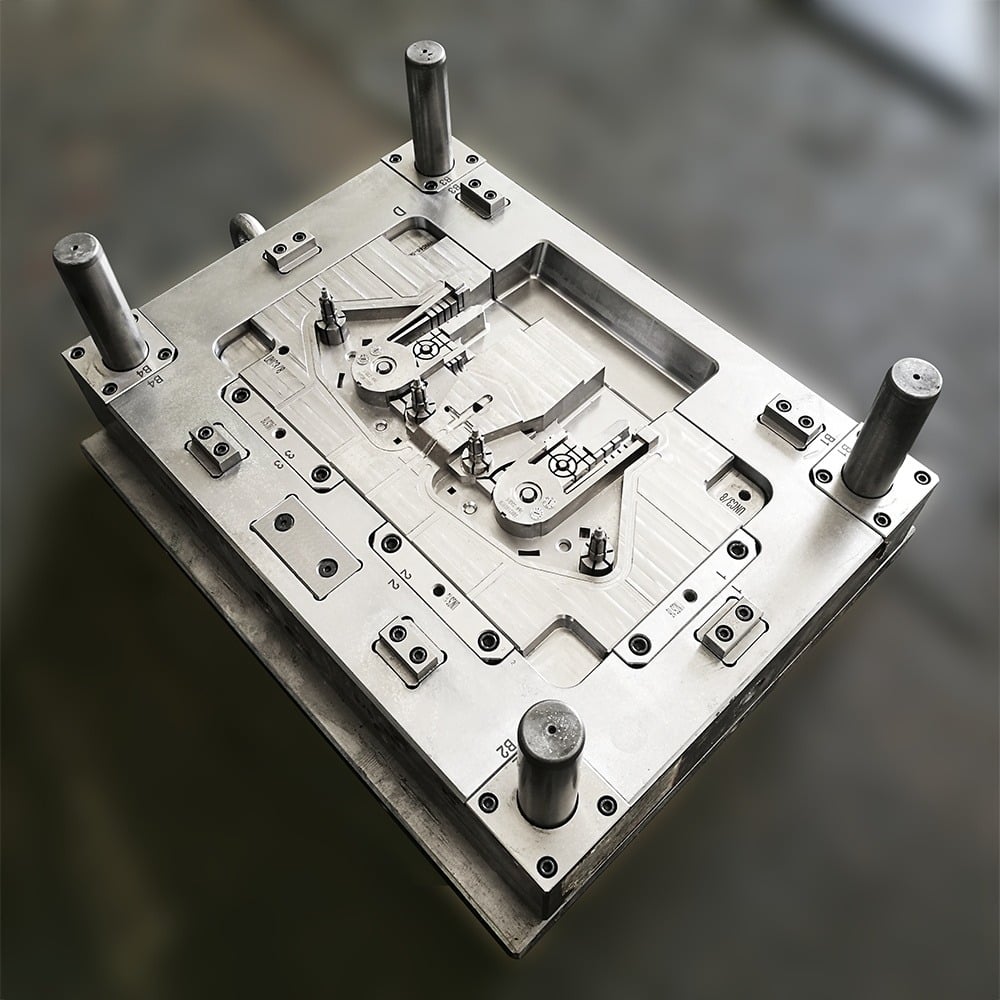

The main role of die etching

Die etching plays a role in decorating products, making them more beautiful and elegant: it overcomes the shortcomings of printing and painting, which are easily worn off.

Die etching meets the visual requirements:.

As the surface of the product as smooth as a mirror is very easy to scratch, easy to get dust and fingerprints, and the blemishes, silk marks and ripples produced in the formation process will be exposed on the smooth surface of the product, and some decorative patterns such as leather pattern, orange peel pattern, wood pattern, rain pattern, matte surface, etc. can hide the shortcomings produced on the surface of the product in the forming process, making the product beautiful in appearance and catering to the visual needs.

The production of patterns can make the surface of the product and the surface of the cavity can accommodate a little air, not to form a vacuum adsorption, making it easy to release the mold anti-slip, anti-rotation, and have a good feel. Make linen surface or matte surface to prevent light reflection, eliminate eye fatigue, etc.