The role of injection mold gate

It is a channel that connects the main flow channel (or manifold) to the cavity. The cross-sectional area of the channel can be equal to that of the main flow path (or manifold), but it is usually reduced. Therefore, it is the smallest part of the entire runner system. The shape and size of the gate have a great influence on the quality of the product.

The function of the gate is to

1. Control the material flow rate

2. prevent backflow during injection due to early solidification of the melt stored in this part, make the melt through the strong shear and increase the temperature, thus reducing the apparent viscosity to improve the flowability and facilitate the separation of the product from the runner system. The design of gate shape, size and location depends on the nature of the plastic, the size and structure of the product.

The general shape of the gate cross-section is rectangular or circular, with a small cross-sectional area and a short length, not only for the above reasons, but also because it is easier to make a small gate larger and more difficult to make a large gate smaller. The location of the gate should generally be chosen in the thickest part of the product without affecting the appearance. The design of the gate size should take into account the nature of the plastic melt. The cavity is the space in the mold where the plastic product is molded.

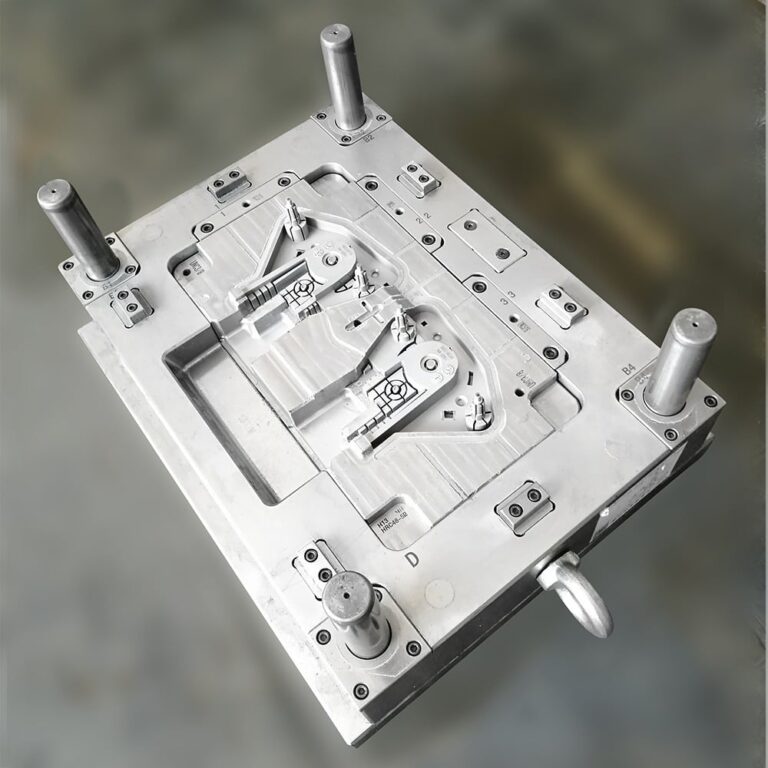

The components used to form the cavity are collectively referred to as molding parts. Each molding part often has a special name. The molding part that forms the shape of the product is called the concave mold (also known as the negative mold), and the one that forms the internal shape of the product (such as holes, slots, etc.) is called the core or convex mold (also known as the positive mold). When designing molding parts, the first step is to determine the overall structure of the cavity according to the properties of the plastic, the geometry of the product, dimensional tolerances and use requirements.

The second is to select the location of the parting surface, gates and venting holes and the release method according to the determined structure. Finally, the design of each part and the combination of each part are determined according to the size of the control product.

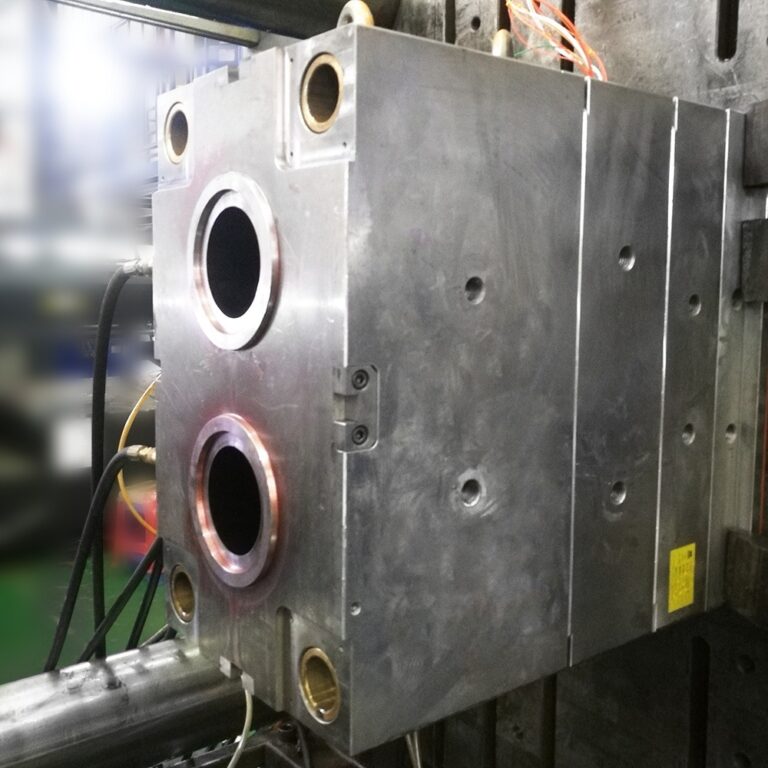

The plastic melt enters the cavity with high pressure, so the molding parts should be reasonably selected and checked for strength and stiffness. In order to ensure the surface of the plastic products and easy to take off the mold, the surface in contact with the plastic, its roughness Ra>0.32um, and to resist corrosion. Formed parts are generally heat-treated to improve the hardness, and the choice of corrosion-resistant steel manufacturing.